Anti-clamping flushing-resistance material door and use method thereof

A technology that is resistant to erosion and materials, applied in valve details, cocks including cut-off devices, engine components, etc., can solve problems such as high flow rate, poor sealing effect, and large sealing surface erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

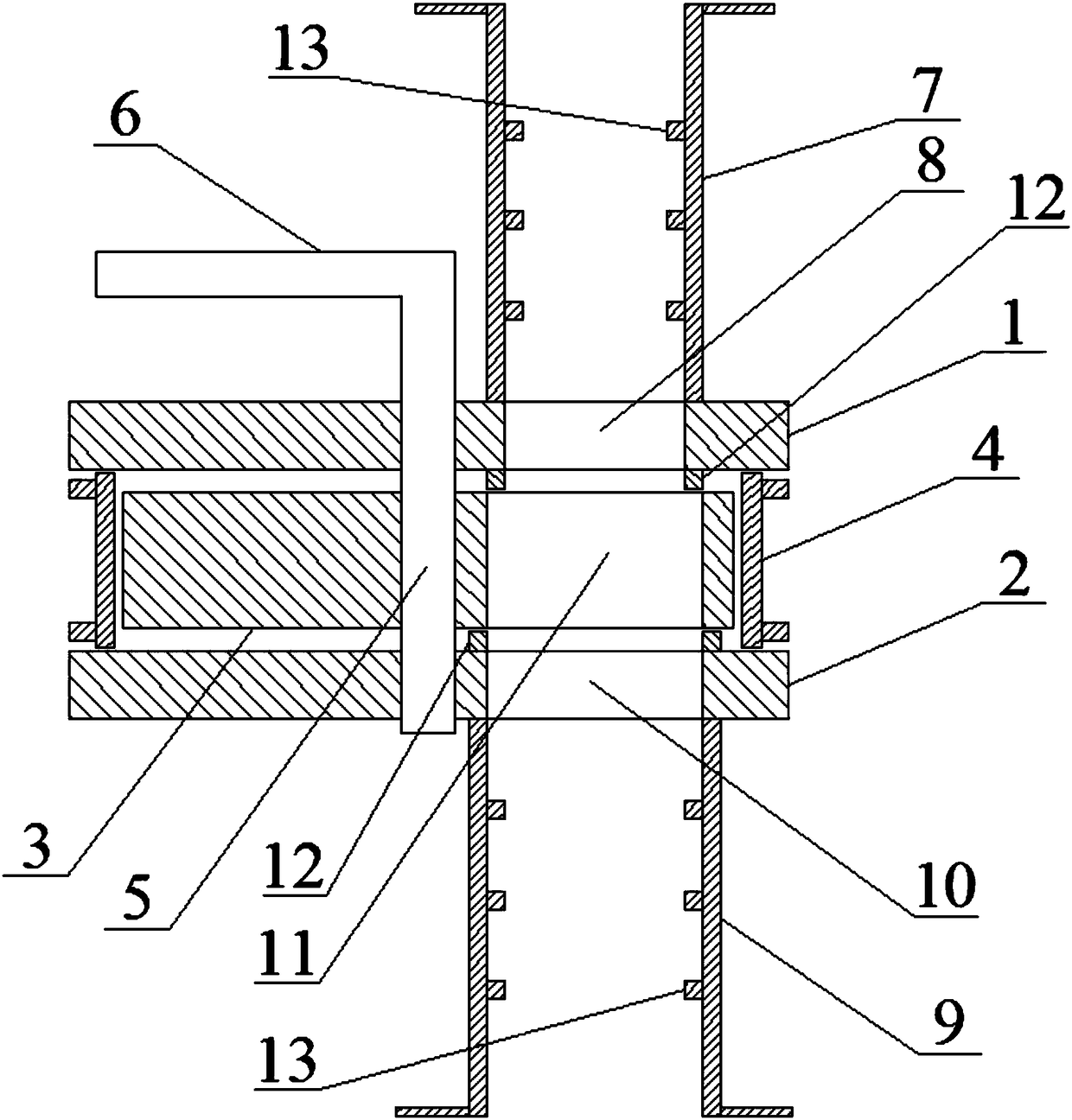

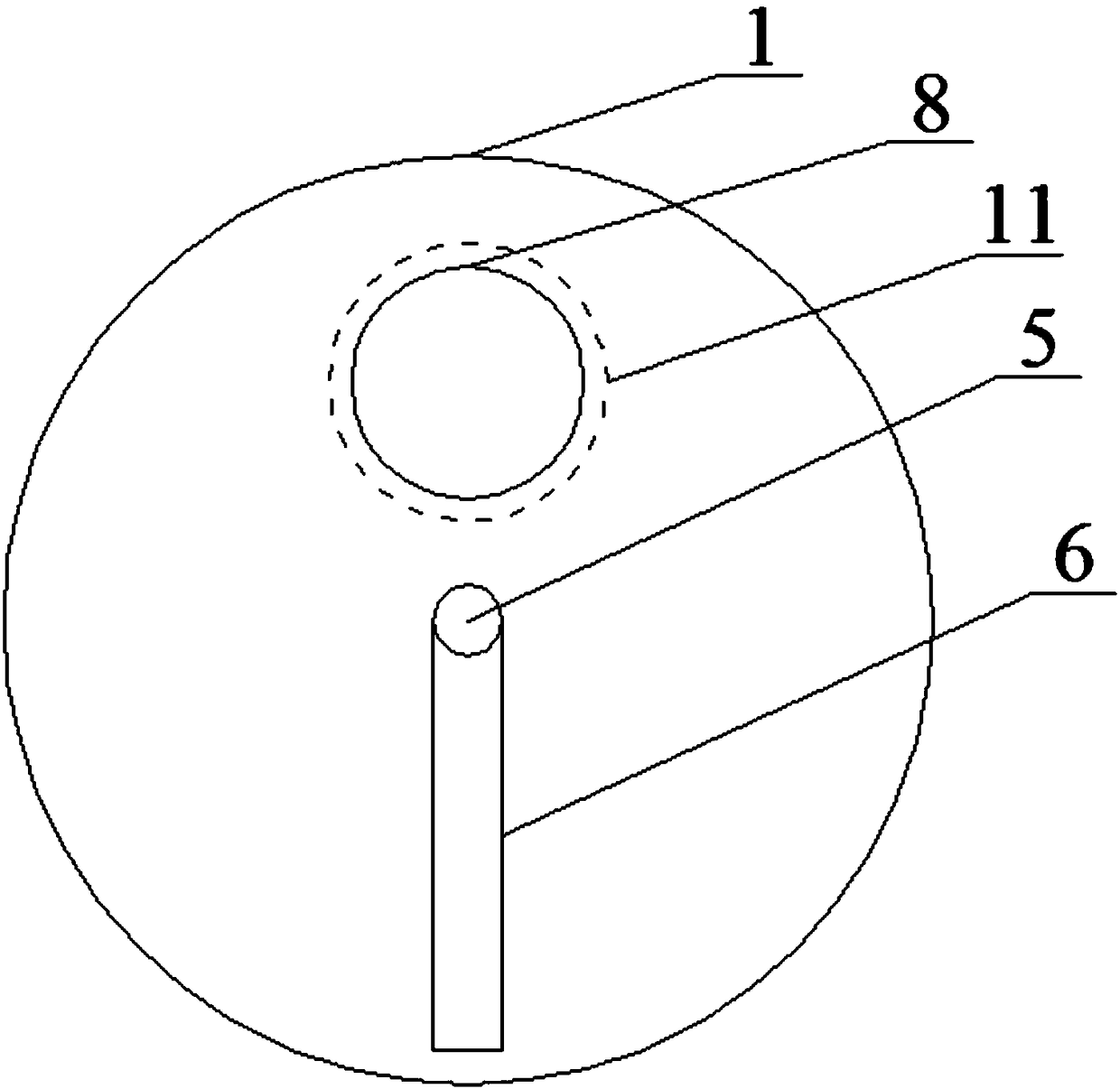

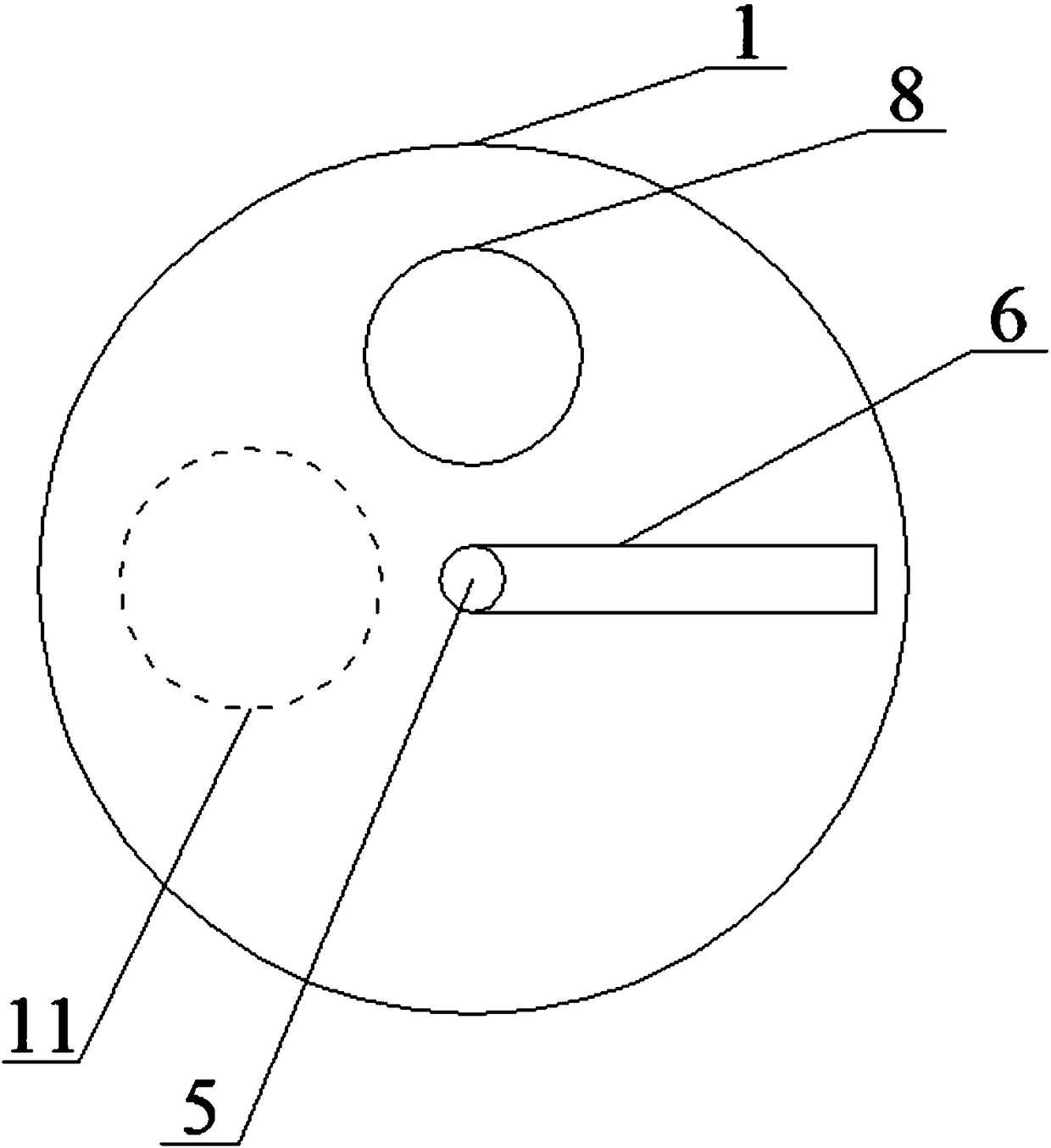

[0033] refer to figure 1 , in the first embodiment given in this paper, the anti-jamming and erosion-resistant material door includes an upper fixed valve plate 1, a lower fixed valve plate 2 and a rotating valve plate 3, and the rotating valve plate 3 is located between the upper fixed valve plate 1 and the lower fixed valve plate. Between the valve plates 2, all three are circular, concentric and parallel up and down. The radii of the upper fixed valve plate 1 and the lower fixed valve plate 2 are greater than the radius of the rotating valve plate 3, and a valve body 4 is arranged around the rotating valve plate 3, and the upper and lower sides of the valve body 4 are closely attached to the upper fixed valve plate 1 and the lower fixed valve plate respectively. The plate 2 protrudes from the part other than the rotating valve plate 3, so that the upper fixed valve plate 1, the lower fixed valve plate 2 and the valve body 4 surround the rotating valve plate 3. The turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com