AB-type water glue laminating process for cambered 3D touch screen or display screen

A touch screen and display technology, applied in the direction of material gluing, data processing input/output process, instruments, etc., can solve the problem of unable to obtain the same shape, and achieve the effect of strong thixotropy, good thixotropy and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

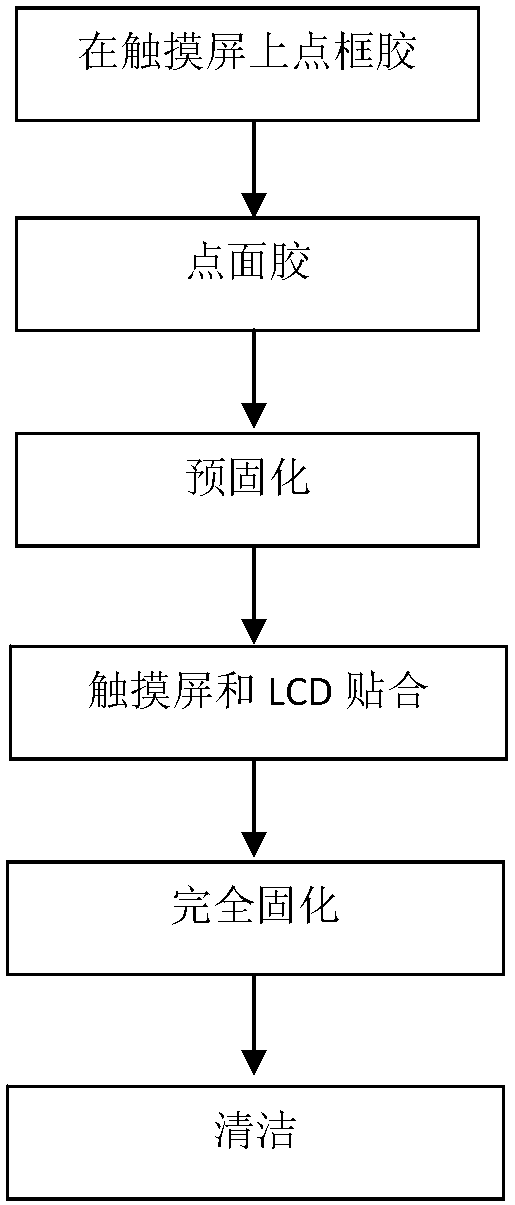

Method used

Image

Examples

Embodiment Construction

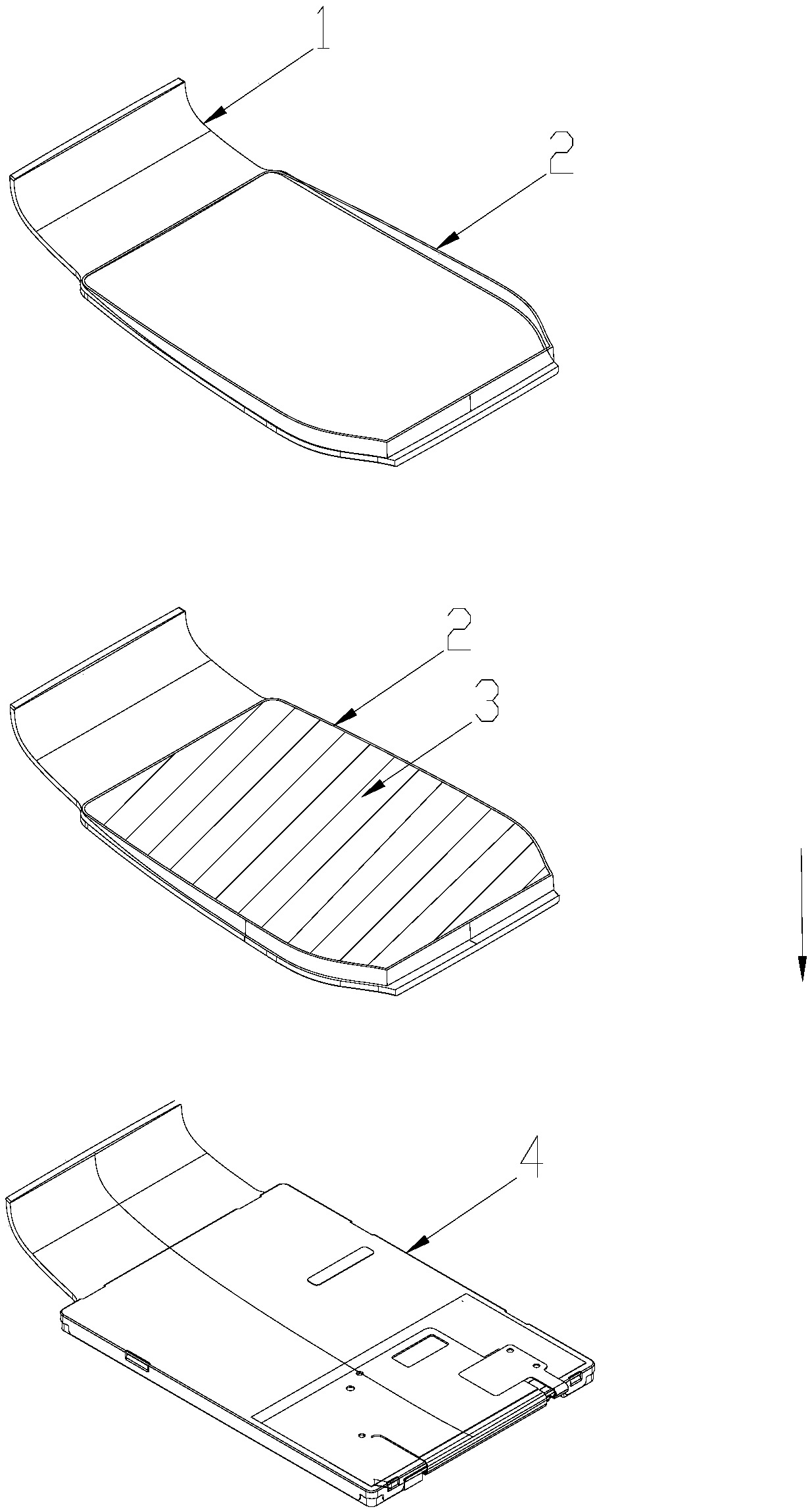

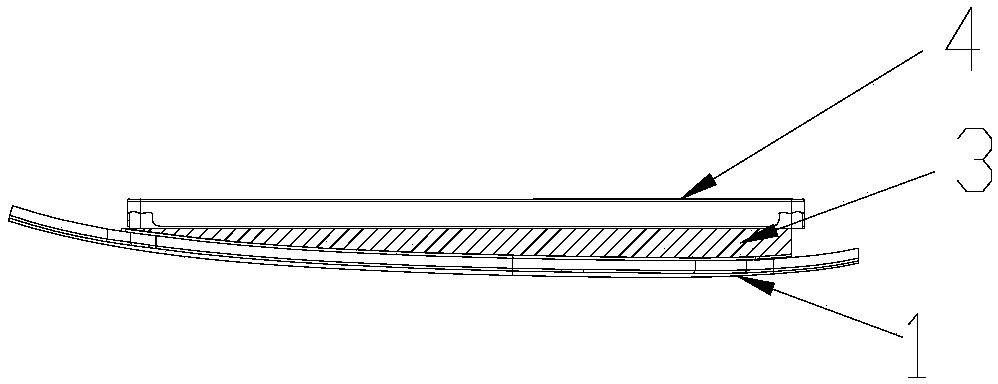

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Refer to attached picture. The glass cover plate 1 of the 3D touch screen of the mobile terminal is a curved 3D structure.

[0021] In the laminating process, the glue A is used as the dam glue, and the surface glue is added with the curing catalyst B glue. Before the surface glue is cured and after curing under the curing conditions, the dam glue is always in a gel state, so that the dam The glue always maintains good thixotropy, and the process method of the present invention does not require the dam glue and surface glue to maintain high-precision flatness, so that the bonding of the curved 3D touch screen has good manufacturability.

[0022] Among them, the B glue and the A glue use the same type of glue, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com