Matte film and preparation method thereof, and haze adjustment method

An adjustment method and technology of fog film, which is applied in the field of optical film, can solve the problems of high surface roughness of finished products, non-adjustable haze of fog film, poor adhesion, etc., and achieve good stability, surface roughness and adhesion improvement , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

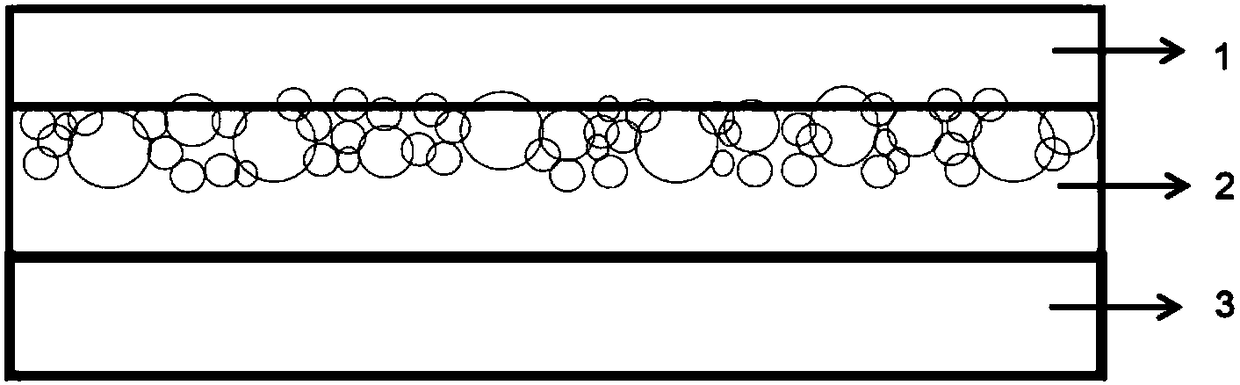

[0052] The matte film described in this embodiment includes a non-matte layer 1 , a matte layer 2 and a substrate layer 3 from top to bottom. The thickness of the non-matte layer 1 is 8 μm, the thickness of the matte layer 2 is 15 μm, and the thickness of the substrate layer 3 is 125 μm.

[0053] The refractive index of the non-matte layer 1 is 1.47. The non-matte layer 1 is formed by photocuring polyurethane acrylic resin (manufacturer: Zhangjiagang Kangdexin resin, model: PD series). The haze of the non-matte layer 1 is 2-3%.

[0054] The matte layer 2 is composed of 100 parts by weight of acrylic resin (manufacturer: Zhangjiagang Kangdexin, model: DBD series), polymethyl methacrylate particles (manufacturer: Sekisui Chemical Industry Co., Ltd., Model: EXM series) 30 parts, dispersant (manufacturer: German BYK Chemicals, model: BYK series) 0.3 parts, ethyl acetate 200 parts and solidified. The particle diameter of the polymethyl methacrylate particles is 5-10 μm, and its ...

Embodiment 2

[0061] The matte film described in this embodiment includes a non-matte layer 1 , a matte layer 2 and a substrate layer 3 from top to bottom. The thickness of the non-matte layer 1 is 8 μm, the thickness of the matte layer 2 is 15 μm, and the thickness of the substrate layer 3 is 125 μm.

[0062] The refractive index of the non-matte layer 1 is 1.47. The non-matte layer 1 is formed by photocuring polyurethane acrylic resin (manufacturer: Zhangjiagang Kangdexin resin, model: PD series). The haze of the non-matte layer 1 is 2-3%.

[0063] The matte layer 2 consists of 100 parts by weight of acrylic resin (KDX model: DBD series), 30 parts of polybutylmethacrylate particles (manufacturer: Soken Chemical Co., Ltd., model: KSR series), Dispersant (manufacturer: German BYK Chemicals, model: BYK series) 0.3 parts, 200 parts of ethyl acetate solidified. The particle size of the polybutyl methacrylate particles is 5-10 μm, and its refractive index is 1.59. The haze of the matte laye...

Embodiment 3

[0070] The matte film described in this embodiment includes a non-matte layer 1 , a matte layer 2 and a substrate layer 3 from top to bottom. The thickness of the non-matte layer 1 is 8 μm, the thickness of the matte layer 2 is 15 μm, and the thickness of the substrate layer 3 is 125 μm.

[0071] The refractive index of the non-matte layer 1 is 1.47. The non-matte layer 1 is formed by photocuring polyurethane acrylic resin (manufacturer: Zhangjiagang Kangdexin resin, model: PD series). The haze of the non-matte layer 1 is 2-3%.

[0072] The matte layer 2 is composed of 100 parts by weight of acrylic resin (manufacturer: Zhangjiagang Kangdexin, model: DBD series), 30 parts of polyurethane particles (manufacturer: Negami Chemical, model: C series), dispersed Agent (manufacturer: German BYK, model: BYK series) 0.3 parts, 200 parts of ethyl acetate solidified. The particle size of the PU particles is 5-10 μm, and its refractive index is 1.49. The haze of the matte layer 2 is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com