Wood gluing device

A gluing device and wood technology, which is applied in the field of wood processing, can solve the problems of low work efficiency and wood glue solidification, and achieve the effects of low cost, improved work efficiency and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

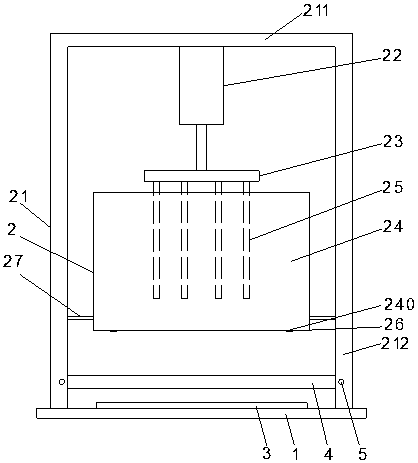

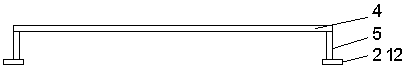

[0016] The present invention as Figure 1-2 Shown, comprise workbench 1, glue dispensing mechanism 2, conveyer belt 3 and scraper 4, described glue dispensing mechanism comprises n-shaped stand 21, motor 22, stirring disc 23 and glue tank 24, and described stand 21 is set On the workbench 1, the stand includes a cross bar 211 and a pair of vertical bars 212, the motor is arranged at the bottom of the cross bar, the motor drives a stirring plate, and the stirring plate is provided with a stirring tube 25, so The glue tank is located between a pair of vertical rods, the glue tank 24 is connected to the vertical rods through a support rod 27, the stirring tube 25 is located in the glue tank, and the bottom of the glue tank 24 is provided with an outlet 240. a closure 26 is provided;

[0017] The transmission belt 3 is arranged on the workbench, the transmission belt 3 is located between a pair of vertical bars, and the transmission belt is located directly below the glue tank; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com