Composite material fan blade leading edge metal reinforcement edge two kinds of blank processing dual-purpose fixture

A technology of fan blades and composite materials, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of complex numerical control program, poor corrosion resistance, narrow tool swing range, etc., to achieve good openness, The effect of preventing deviation from the processing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

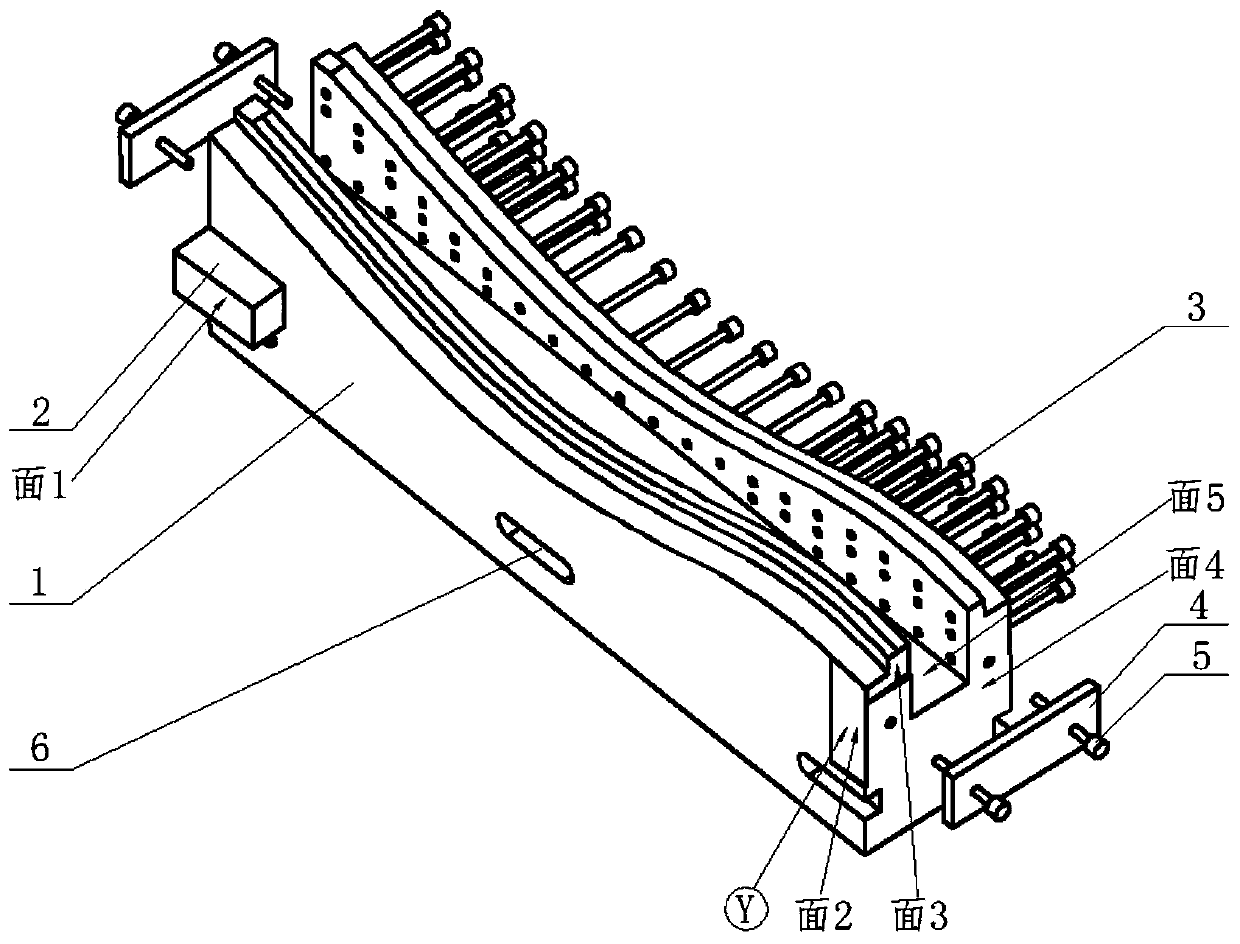

[0045] The structural principle and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

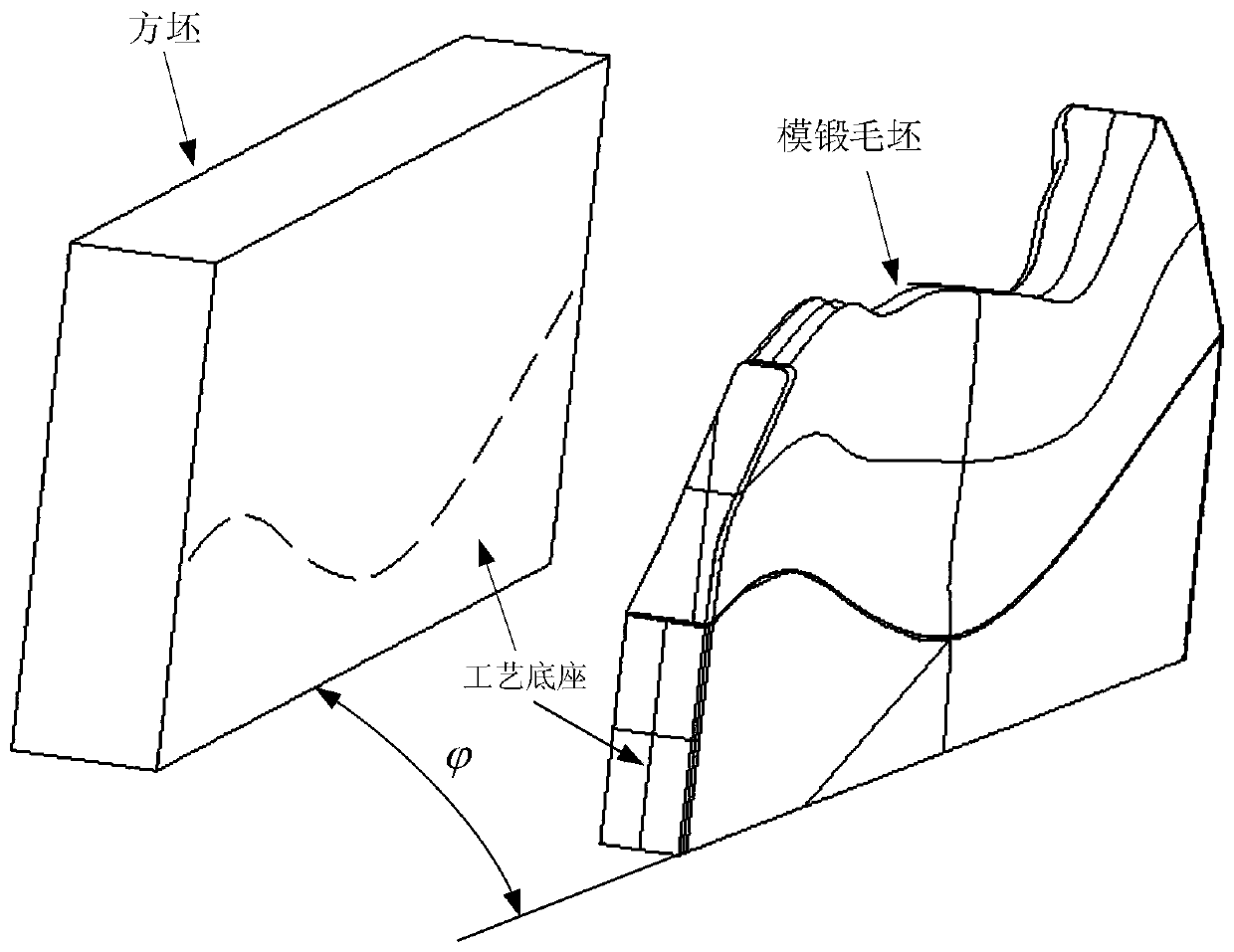

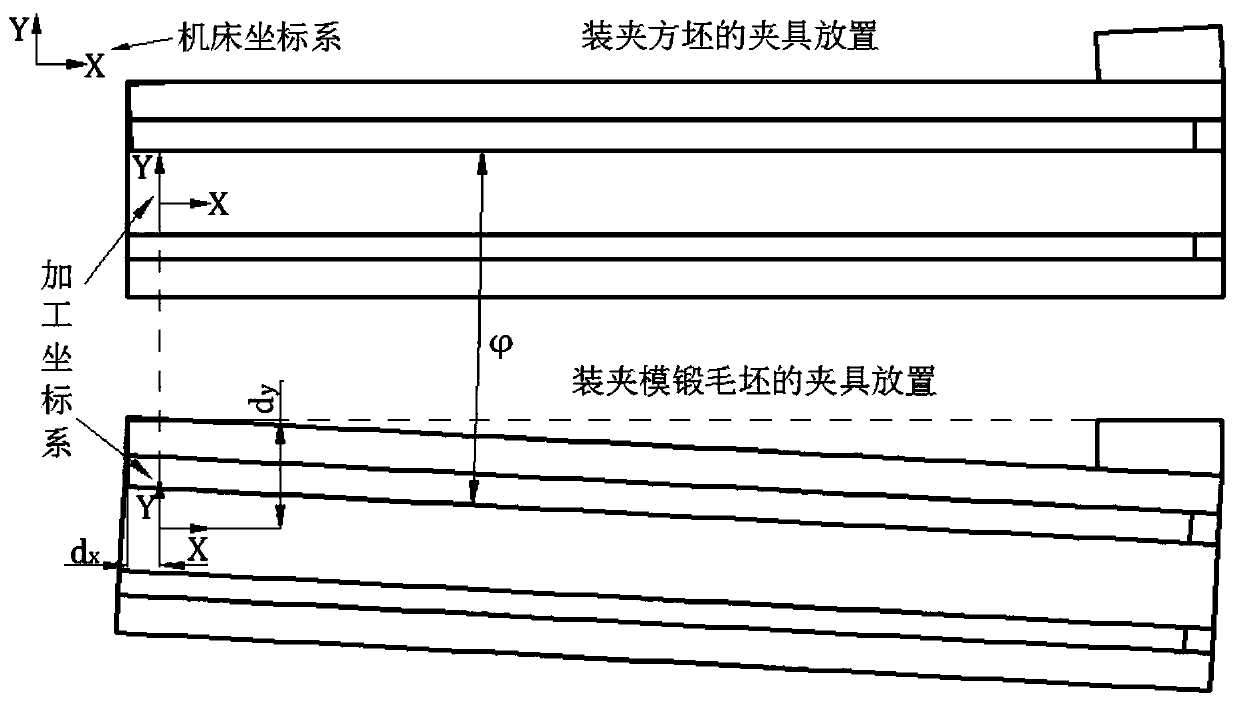

[0046] The present invention provides a composite material fan blade leading edge metal reinforcement edge two kinds of blank processing dual-purpose fixture, in order to describe this technical solution more clearly, but does not limit the direction of this technical solution, with image 3 Define the directions of the six faces of the base 1 as an example: the opening of the square slot is set as the top face of the base 1, and the opposite face is the bottom face; the side of the base 1 provided with the coordinate conversion block 2 is the front face, and the opposite face is the rear face , whose left and right sides are the left and right sides, respectively.

[0047] The fixture includes a hexahedral base 1, and the top surface of the base 1 is provided with square grooves running through the left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com