A semiconductor light-emitting diode manufacturing equipment

A technology of light-emitting diodes and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low safety, potential safety hazards, inconvenient assembly and replacement of rotary knives, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

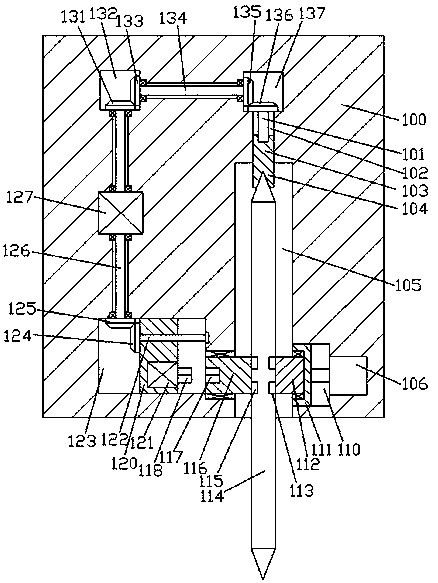

[0014] Combine below Figure 1-4 The present invention will be described in detail.

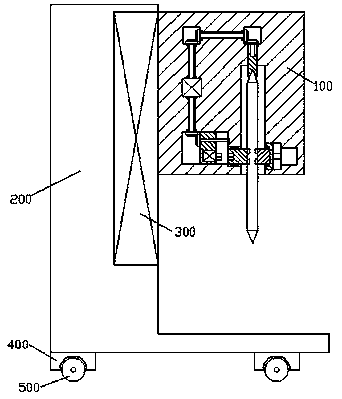

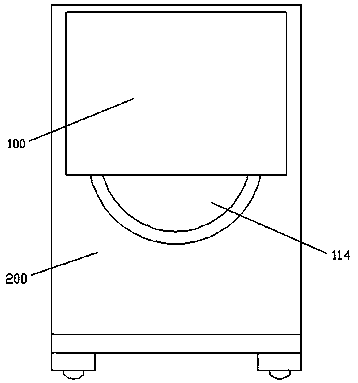

[0015] refer to Figure 1-4 According to an embodiment of the present invention, a semiconductor light-emitting diode manufacturing equipment includes a manufacturing frame body 100, the manufacturing frame body is installed on the right end surface of the support 200 through a lifting device 300, and the bottom end surface of the support 200 is fixed around A foot column 400 is provided, and a roller 500 is installed for rolling fit in the bottom end surface of the foot column 400, and a fitting cavity 105 is arranged in the bottom end surface of the manufacturing frame body 100, and a rotating knife is installed in the fitting cavity 105 for rotation fit. 114, the inner wall on the right side of the fitting cavity 105 is provided with a snap-fit assembly for locking and fitting connection with the rotary knife 114, and the inner wall of the manufacturing frame 100 on the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com