Ultra-soft cable for robot arm and processing method of ultra-soft cable

A robotic arm and ultra-soft technology, applied in bendable cables, insulating cables, insulating conductors/cables, etc., can solve the problems of thin conductors, conductive performance, reduced conductor service life, and low mechanical strength of soft copper wires, etc. Achieve the effect of improving flexibility and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

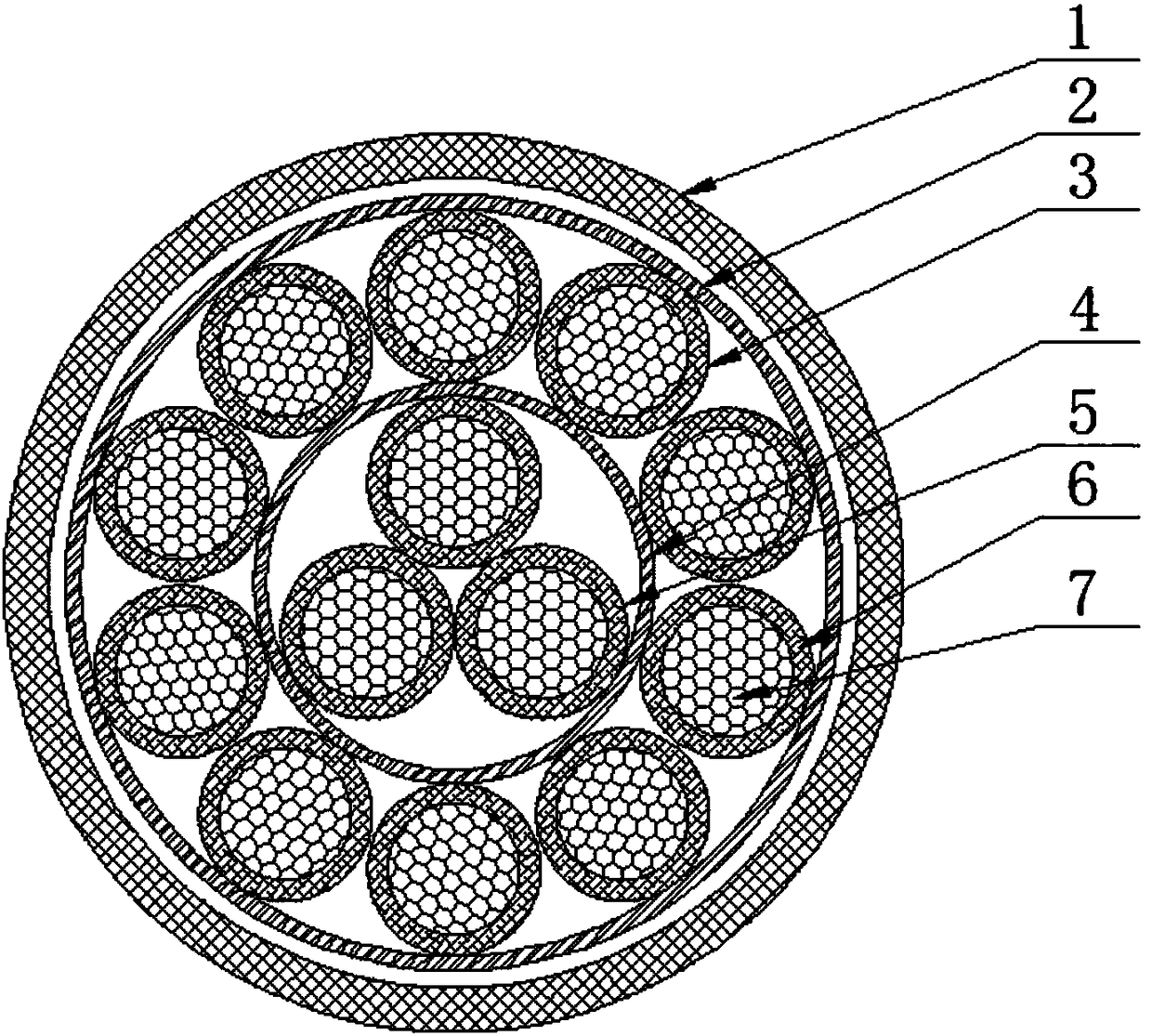

[0029] An ultra-soft cable for a robot arm, comprising one or more layers of insulated cable cores, in this embodiment figure 1 Among them, two layers of insulating cable cores are included, the inner insulating cable core 5 is three cores, and the outer insulating cable core 3 is ten cores. There is a sheath layer 1 on the outside of the outer insulating cable core, and each insulating cable core includes a conductor 7 and an insulating layer 6. synovial layer.

[0030] The outer surface of the outer insulating cable core between the outer insulating cable core and the sheath layer is wrapped with non-oriented polytetrafluoroethylene film to form an outer sliding film layer 2 . The outer surface of the inner insulating cable core between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com