Waterproof type optical fiber connector

An optical fiber connector, waterproof technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of not being a whole, not small enough, inconvenient to use, etc., to achieve a reasonable and compact structure, strong self-locking function, plug Pull the easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

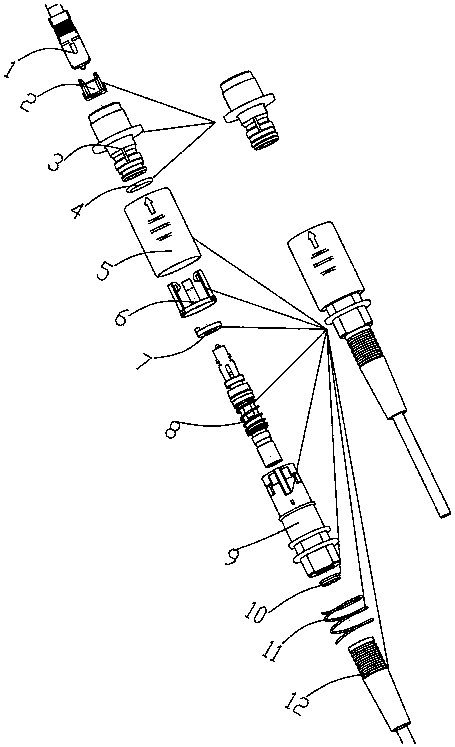

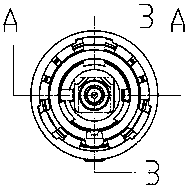

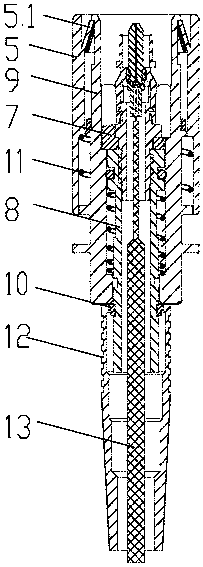

[0025] An embodiment of the present invention, as shown in the drawings, includes two parts: an adapter assembly and a connector assembly, the adapter assembly includes an adapter cylinder 3, and the adapter cylinder includes a front end and a rear end , a stop shoulder with a larger outer diameter is set between the front and rear ends, a sealing groove is arranged in front of the outer periphery of the front end head, and a sealing ring 4 is installed in the sealing groove, and a sealing ring 4 is arranged behind the outer periphery of the front end head There is an annular clamping groove with a trapezoidal radial cross-section, and the inner hole of the adapter cylinder is a stepped inner hole, which is small at the front and large at the rear; a guide flange 3.1 is also provided on the outer periphery of the front end, which is connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com