Temperature measurement system based on fracturing pump plunger

A measurement system and fracturing pump technology, which are applied in the fields of oil drilling and production engineering and petrochemical equipment, can solve the problems of fracturing safety accidents, blank research on inventions, etc., and achieve the effect of improving safety work and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

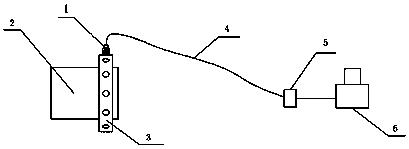

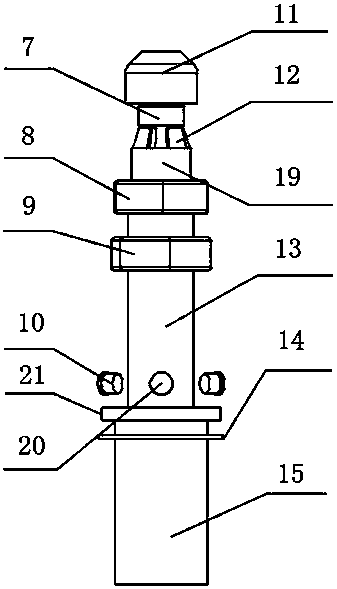

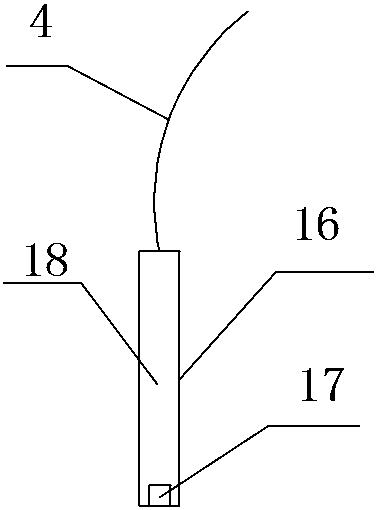

[0023] like figure 1 As shown, a temperature measurement system based on the surface of the fracturing pump plunger includes a plunger 2, a fracturing pump plunger seal assembly 3, a temperature sensor joint 1, a temperature sensor 18, a signal line 4, a data acquisition box 5 and a computer 6. The body of the sealing assembly 3 is provided with through holes evenly arranged according to a certain size, such as figure 2 As shown, the temperature sensor connector 1 is provided with a sensor outer connector 15 and a sensor inner connector 13, and is a hollow T-shaped column structure. The sensor outer connector 15 is placed in the through hole of the sealing assembly 3, and is controlled by a strong magnetic The gasket 14 is fixed on the sealing assembly 3, the sensor inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com