Triple pressure safety protection system and method for thermal compounding loading equipment of explosive force

A technology for loading equipment and safety protection, which is applied in the direction of offensive equipment, electrical transmission signal system, ammunition, etc., can solve the problems of protection strength and effect, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] as attached figure 1 As shown, a triple pressure safety protection system for explosive force-heat composite loading equipment includes a mechanical hydraulic switch 5 located on the column 2 of the main engine 1, a measuring sensor 6 located on the main engine oil cylinder 3 and a safety sensor 7 located at the hydraulic station 4, The measurement sensor and the safety sensor realize the calculation and control of the measurement data through PLC.

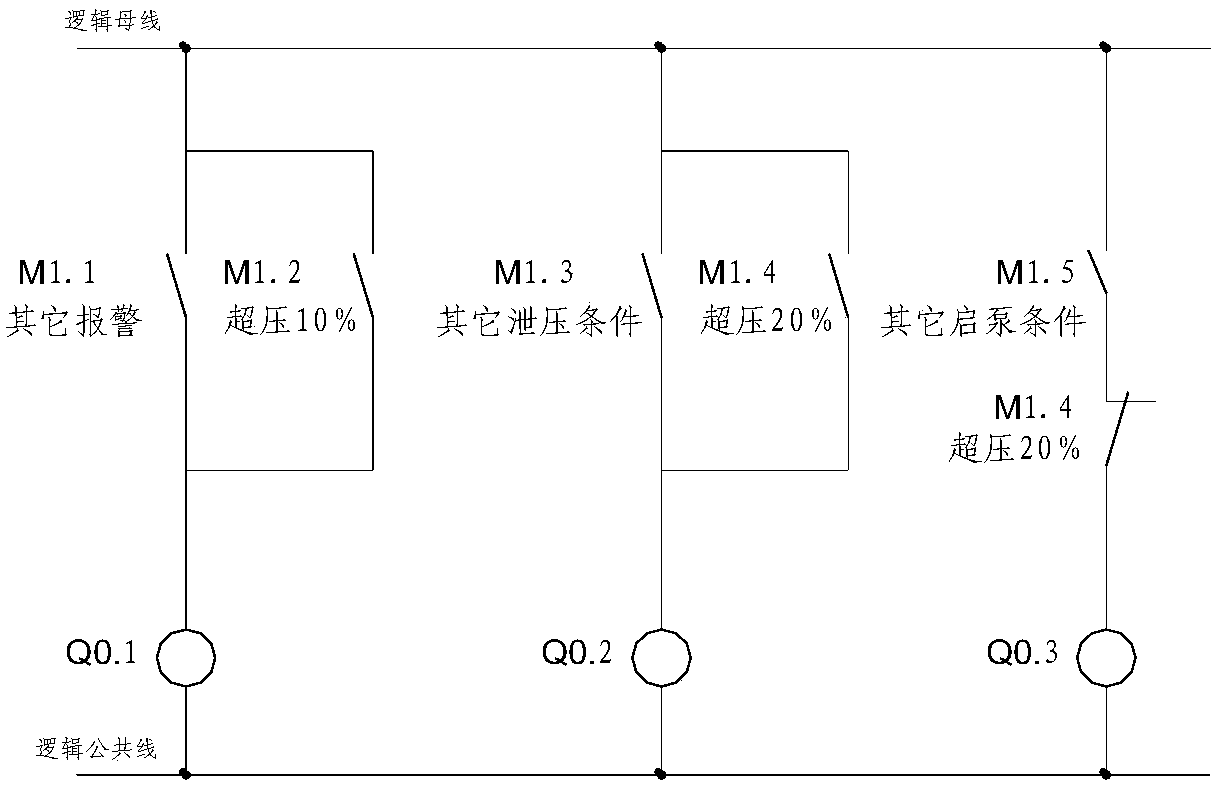

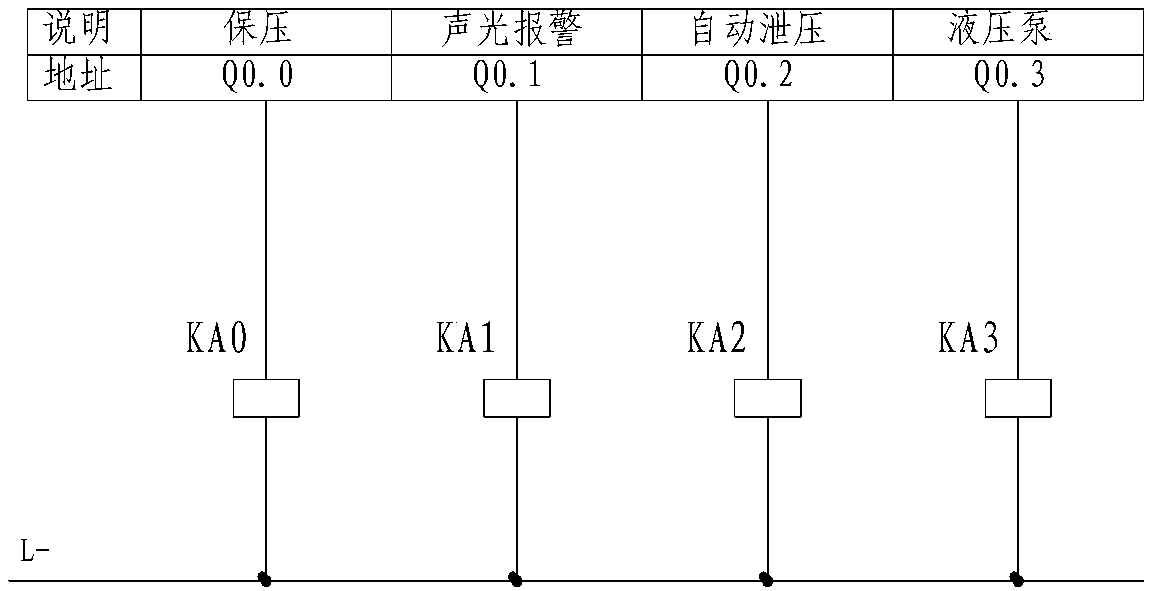

[0020] as attached figure 2 As shown, the pressure automatic protection logic control is realized by PLC. When the measurement sensor measures the current pressure value, the CPU automatically calculates it according to the set value. When it judges that the overpressure is 10%, the logic relay M1.2 is closed, so that the Q0.1 of the PLC is connected. If the measuring sensor fails, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com