A kind of preparation method of antistatic strong hydrophobic composite film layer

A composite film layer and hydrophobic technology, which is applied in the field of composite materials, can solve the problems of difficult film preparation, poor purity of polytetrafluoroethylene materials, damage to the matrix material, that is, the life of electronic devices, etc., to achieve easy control of thickness, less impurities, Effect that thickness is possible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

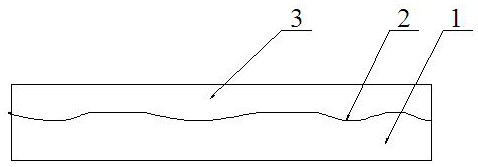

[0035] Such as figure 1 As shown, the composite film layer of the present invention includes a conductive metal layer, grooves and a polytetrafluoroethylene layer.

[0036] A preparation method for an antistatic strong hydrophobic composite film layer, comprising the following steps:

[0037] Step 1. Using the magnetron sputtering coating equipment, the substrate is used as the substrate of the equipment, and Ti is used as the target to perform magnetron sputtering coating, so that the surface of the substrate is coated with a 200nm thick Ti metal layer, and a metallized substrate is obtained. surface material;

[0038] Among them, the power of the magnetron sputtering coating equipment is 200~300W; the internal pressure of the chamber of the magnetron sputtering coating equipment is 0.5~0.8Pa. The electrons collide with the argon atoms under the action of the electric field, and a large amount of argon ions and electron plasma are ionized. Atoms of Ti metal target are depo...

Embodiment 2

[0046] Such as figure 1 As shown, the composite film layer of the present invention includes a metal layer, grooves and a polytetrafluoroethylene layer.

[0047] A preparation method for an antistatic strong hydrophobic composite film layer, comprising the following steps:

[0048] Step 1: Using magnetron sputtering coating equipment to prepare a metallized Al layer, the preparation process is: the power of the magnetron sputtering coating equipment is 200W; the internal pressure of the chamber is 0.5Pa during operation;

[0049] Step 2, using argon ions to bombard the surface of the metal layer, the preparation process is as follows: the process parameters of the IBE equipment are: screen voltage: 500V, screen current: 250mA, cavity Ar gas flow rate: 10sccm; groove depth: 80nm;

[0050] Step 3, using plasma enhanced chemical vapor deposition equipment to prepare Teflon film, the preparation process is as follows: the radio frequency power is 50W, and the upper and lower plat...

Embodiment 3

[0053] Such as figure 1 As shown, the composite film layer of the present invention includes a metal layer, grooves and a polytetrafluoroethylene layer.

[0054] A preparation method for an antistatic strong hydrophobic composite film layer, comprising the following steps:

[0055] Step 1: Use magnetron sputtering coating equipment to prepare a metallized Cu layer. The preparation process is: the power of the magnetron sputtering coating equipment is 280W; the internal pressure of the chamber is 0.8Pa during operation;

[0056] Step 2, using argon ions to bombard the surface of the metal layer, the preparation process is: the process parameters of the IBE equipment are screen voltage: 520V, screen current: 235mA, cavity Ar gas flow rate 12sccm; groove depth is 80nm;

[0057] Step 3, using plasma enhanced chemical vapor deposition equipment to prepare Teflon film, the preparation process is as follows: the radio frequency power is 80W, and the upper and lower plate voltages of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com