Logistics goods storage system and method

A storage system and cargo technology, which is applied in the field of logistics cargo storage system, can solve the problems of increased labor intensity and low efficiency, and achieve the effects of improving work efficiency, improving storage efficiency, and increasing travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

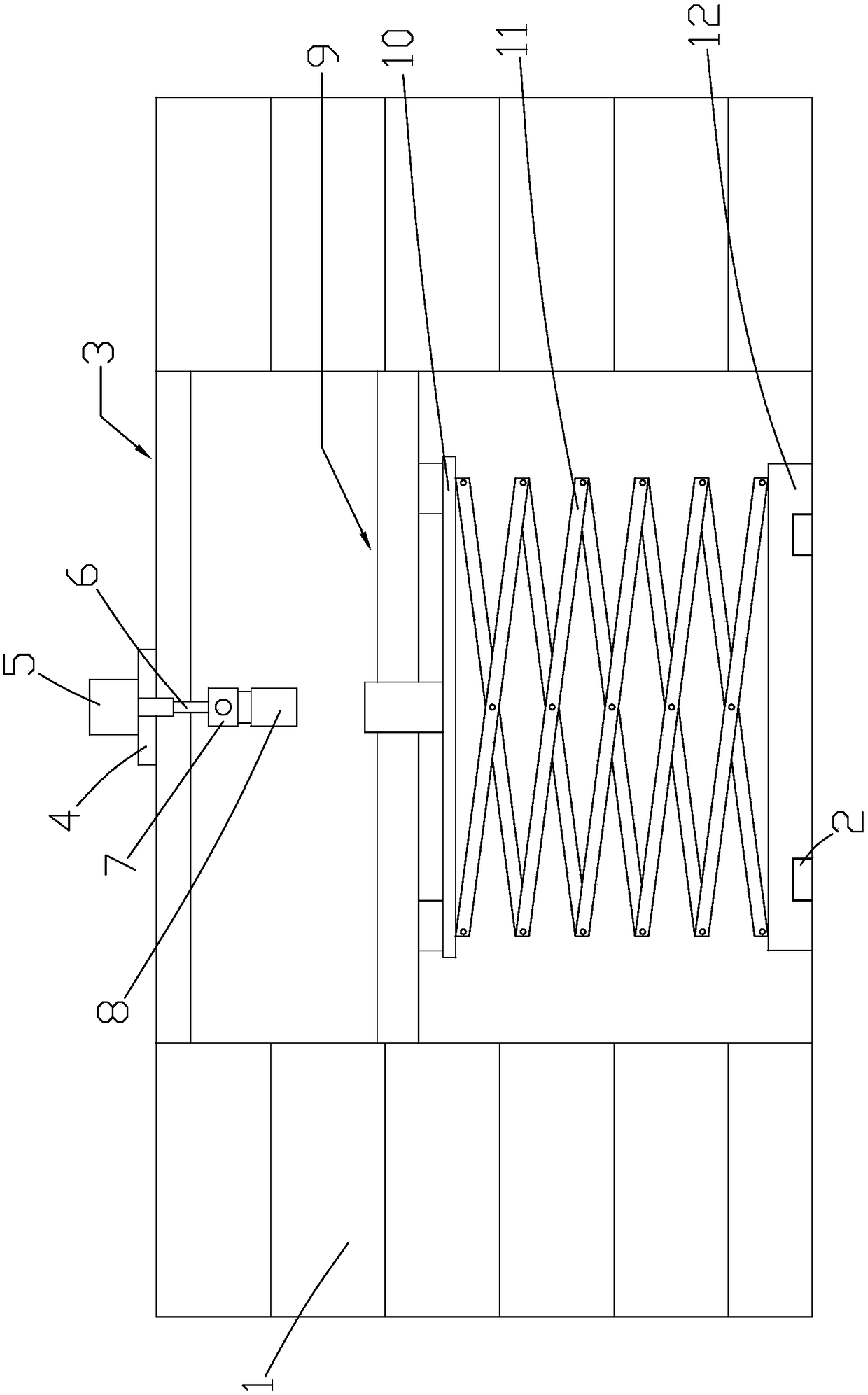

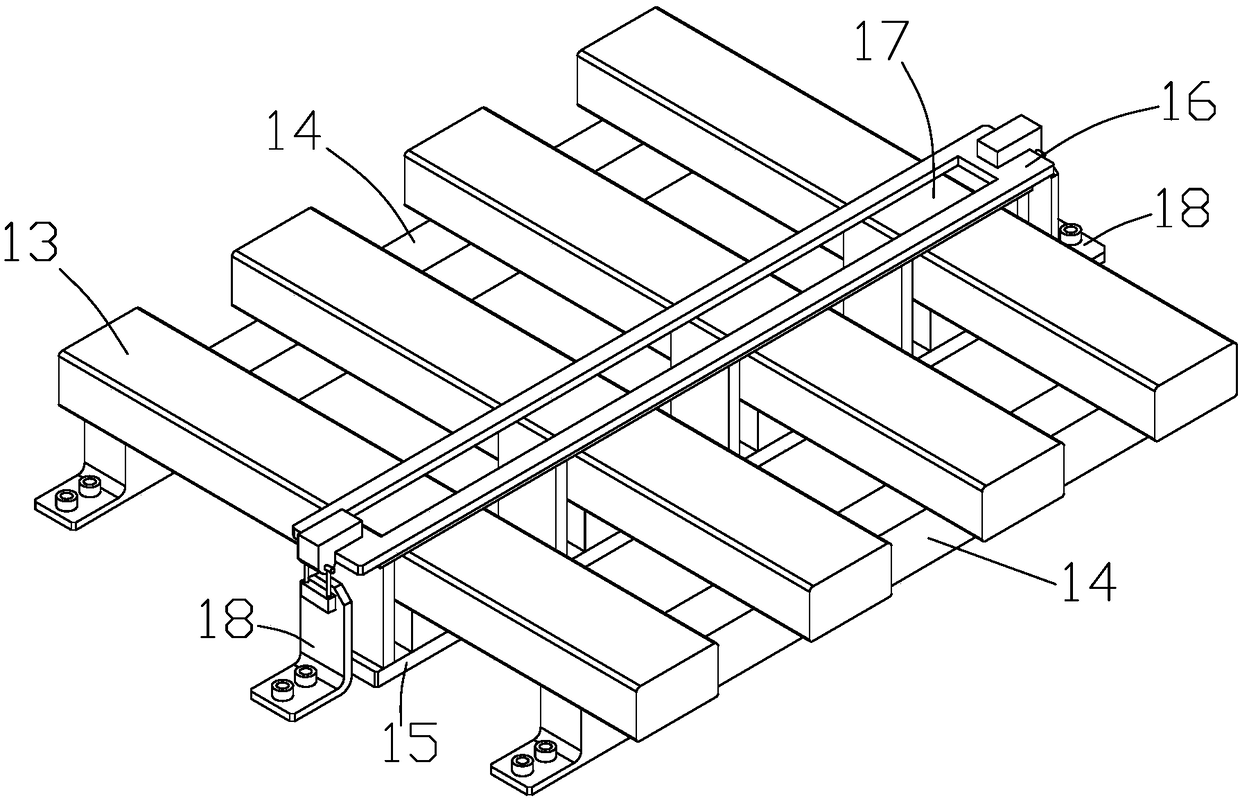

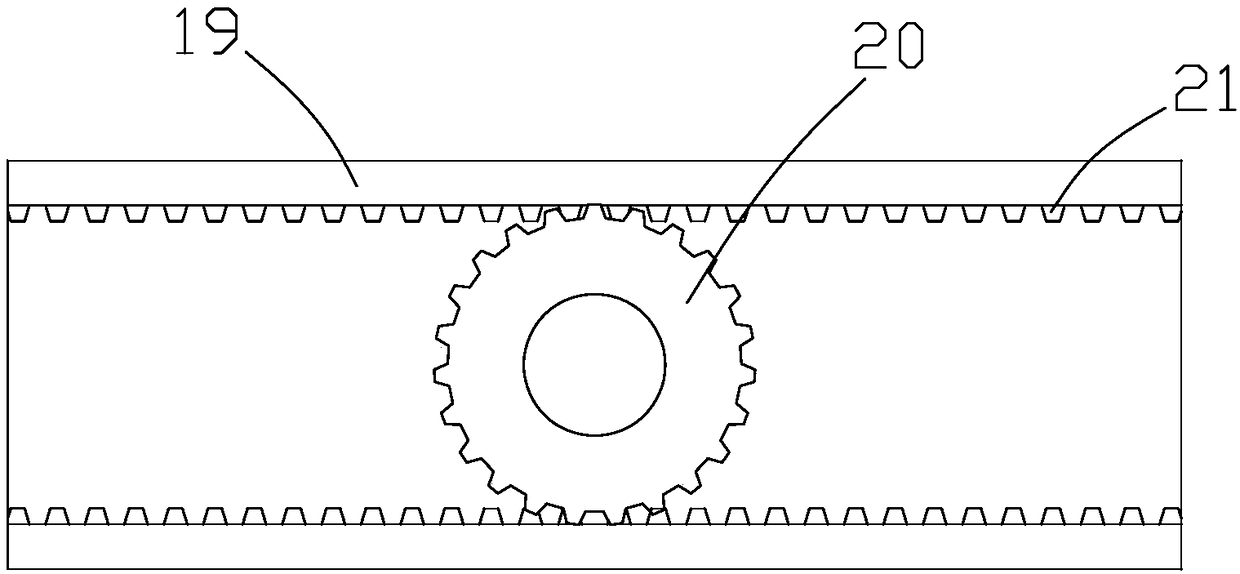

[0046] Such as Figure 1 to Figure 6 As shown, it is a logistics cargo storage system of the present invention, including a storage rack 1, an automatic storage device 9, a suspension mechanism 3, a horizontal booster mechanism 7 and a clamping mechanism 8, and the automatic storage device 9 is located on two storage racks 1 Among them, the automatic storage device 9 includes four conveying mechanisms 13 arranged parallel to each other. The conveying mechanisms 13 are fixedly connected to the lifting plate 10 through the first support frame 14 and the second support frame 15. The two first support frames 14 are symmetrically arranged. On both sides of the second support frame 15, the top surface of the second support frame 15 is fixedly connected with a top plate 16, the top plate 16 is located above the conveying mechanism 13, and the top plate 16 is provided with a limiting groove 17, and the two sides of the top plate 16 pass through auxiliary The block 18 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com