Automatic punching and threading binding machine

A binding machine, automatic technology, applied in binding and other directions, can solve the problems of cumbersome operation and low efficiency of binding machine, and achieve the effect of continuous wire feeding and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

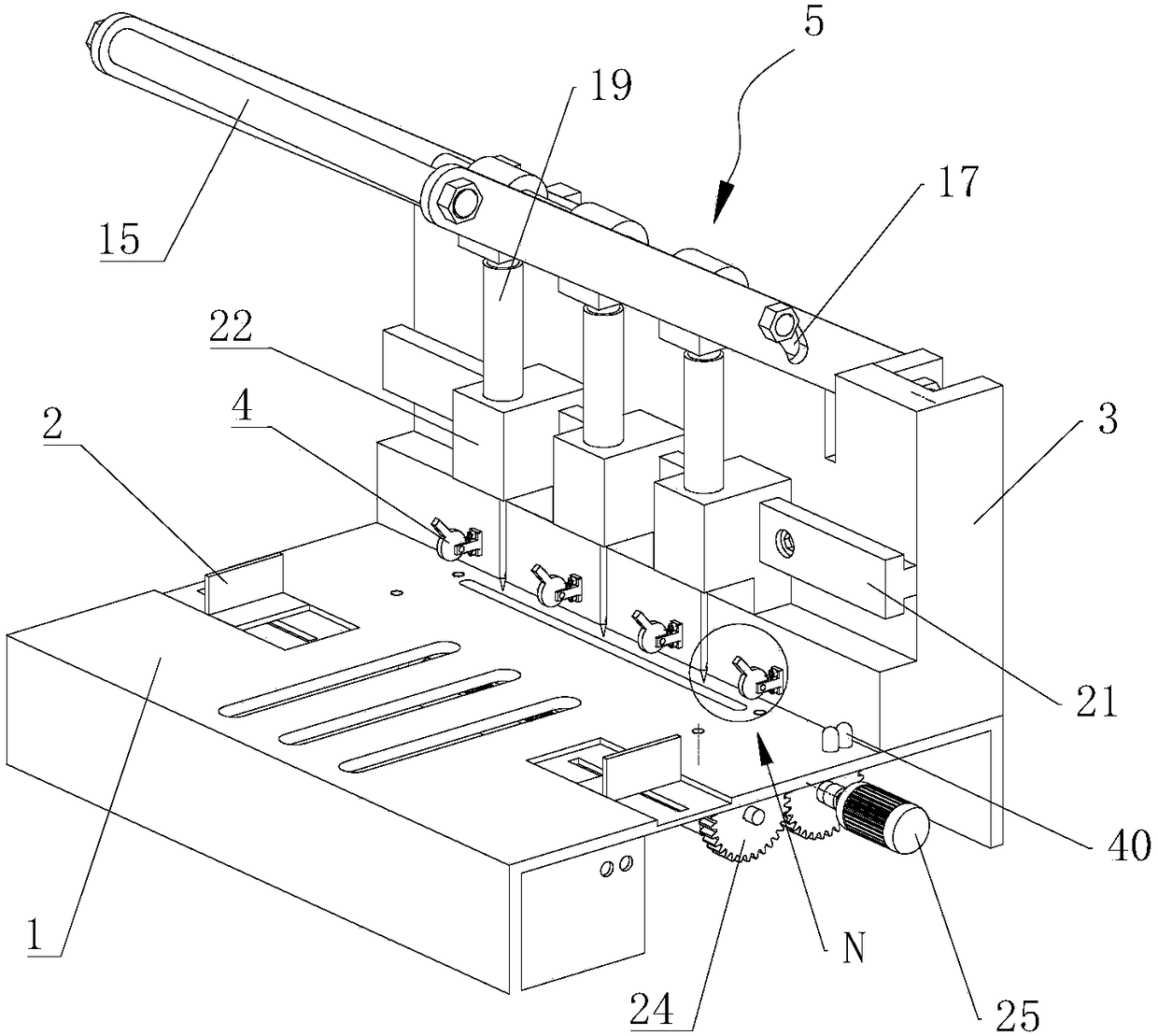

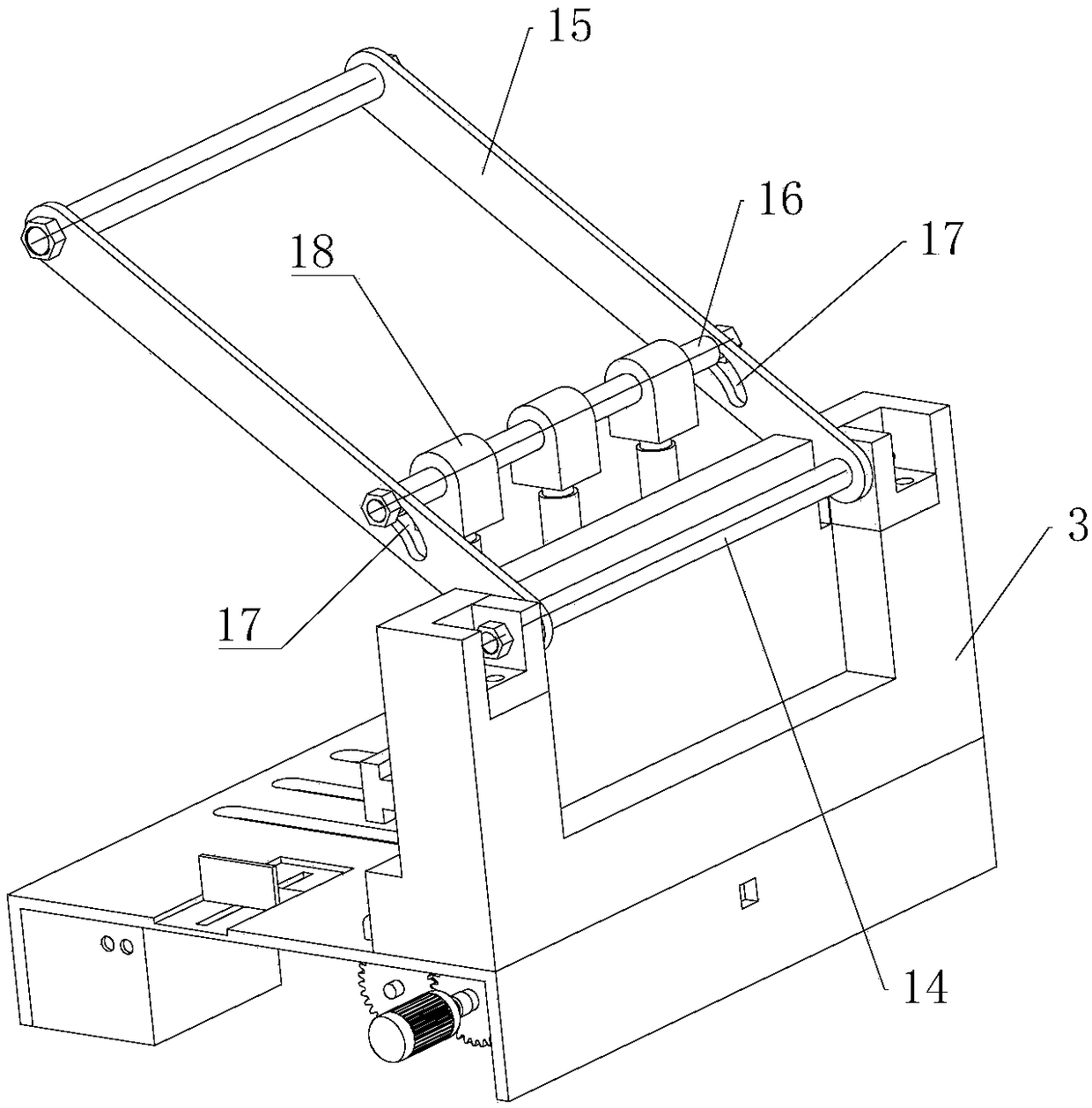

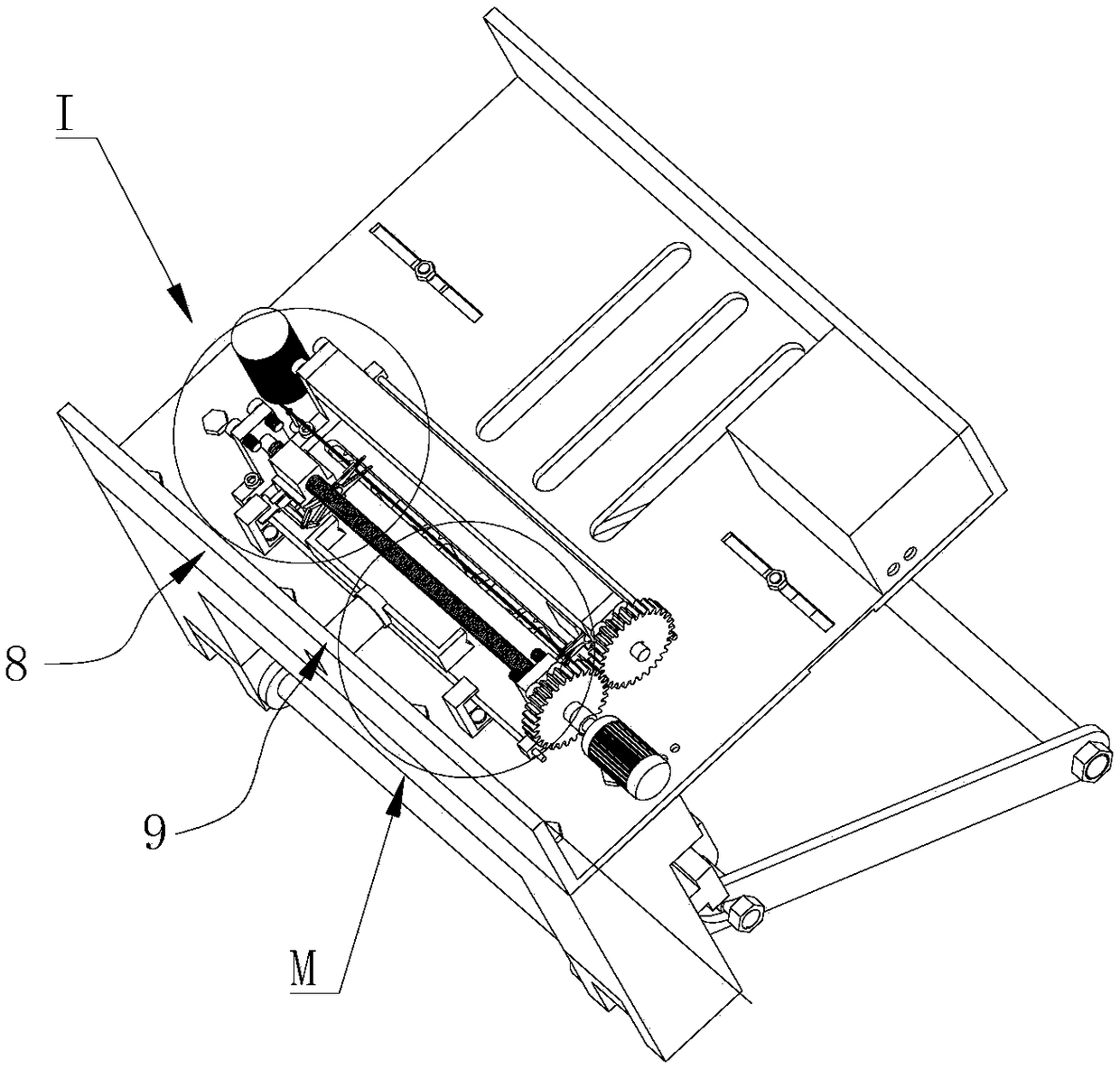

[0047] Such as figure 1 , figure 2 and image 3 As shown together, they are structural schematic diagrams of three different viewing angles of an embodiment of an automatic punching and threading binding machine of the present invention. This embodiment is mainly composed of the following parts: a paper placing table 1, a rear support table 3, and a paper pressing mechanism 4 , needle pressing mechanism 5, thread feeding and trimming mechanism 8, and thread pushing mechanism 9. The structure of each mechanism will be described in detail below.

[0048] The upper surface of the paper table 1 is arranged horizontally so that the papers to be bound are laid flat, and the paper table 1 is provided with a cardboard stopper 2. The paper stopper 2 is a relatively common structural feature in the prior art, and its structure will not be repeated here. repeat. A rear support platform 3 is fixed behind the paper placing table 1, and the rear support platform 3 is mainly used as a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com