Manhole cutting auxiliary tool suitable for different round covers

A technology for auxiliary tooling and round covers, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of low efficiency and poor precision, and achieve small installation errors, high cutting precision, and good contour of manholes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

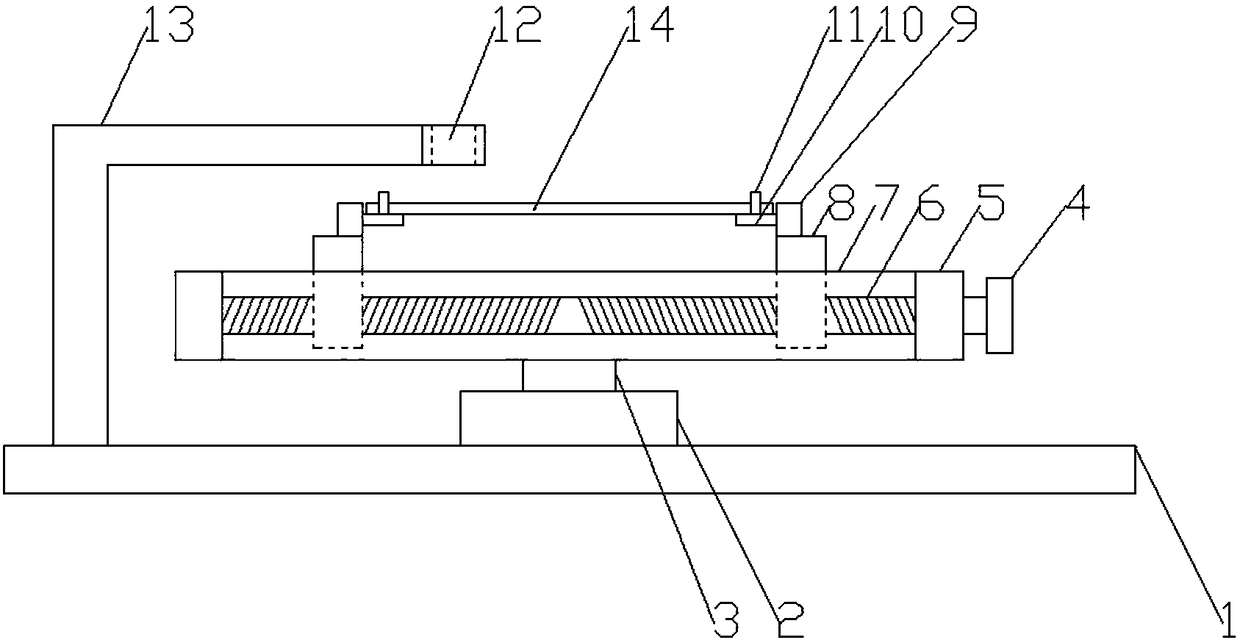

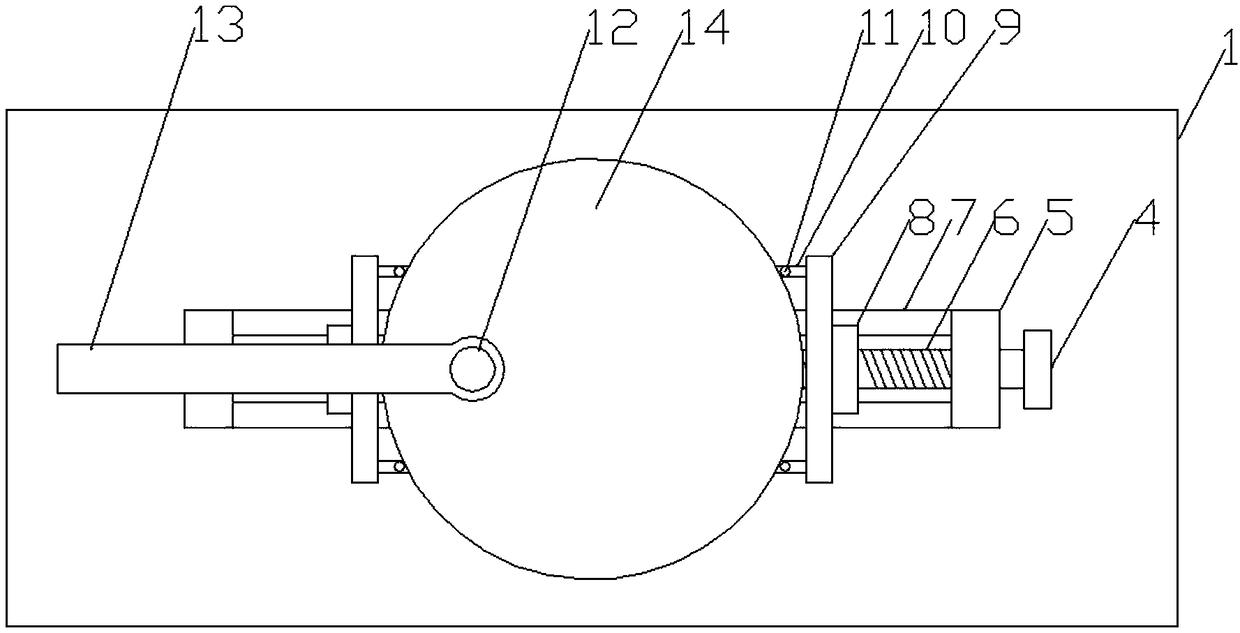

[0011] Figure 1-2 The specific embodiment of the present invention is shown: a manhole cutting auxiliary tool suitable for different round covers, including a base plate 1, a rotating seat 2 is provided on the upper end of the base plate 1, and a rotating shaft 3 is arranged inside the rotating seat 2. The upper end of the rotating shaft 3 is fixed with a slide table 7, the two ends of the slide table 7 are provided with a screw seat 5, and the two-way screw rod 6 is arranged in the screw seat 5, and the two-way screw rod 6 is located inside the slide table 7, so The center of the two-way screw rod 6 coincides with the center of the rotating seat 2, and the two-way screw rod 6 is provided with two center-symmetrical slide seats 8, and the upper end of the slide seat 8 is fixed with an upper support plate 9. The side of the plate 9 pointing to the center of the two-way screw rod 6 is provided with two support rods 10, the support rods 10 are symmetrical with respect to the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com