Sunflower seed unhusking equipment for food

A technology for sunflower seeds and food, applied in the field of sunflower seed shelling equipment for food, can solve the problems of difficult batch shelling, decreased appetite, dull taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

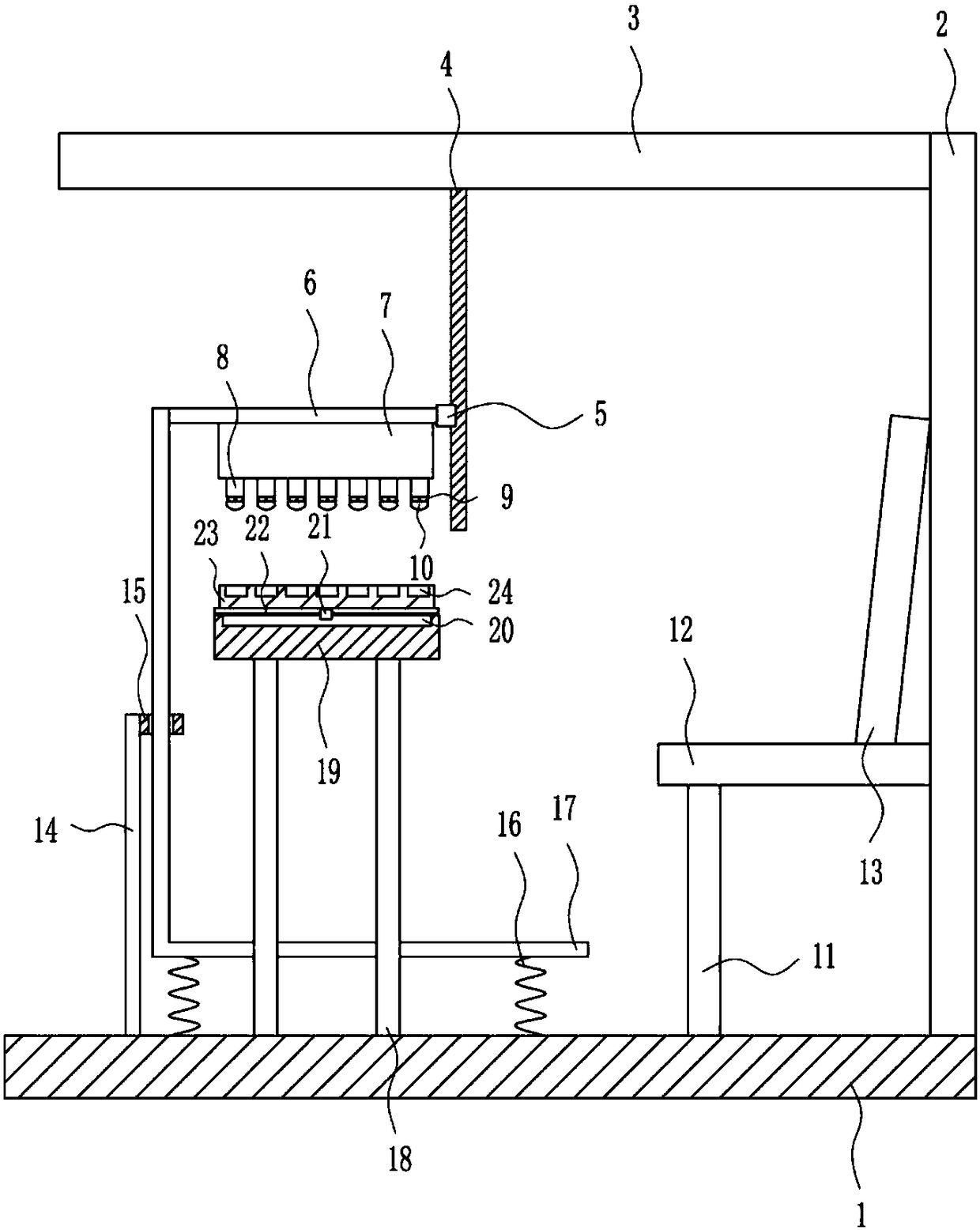

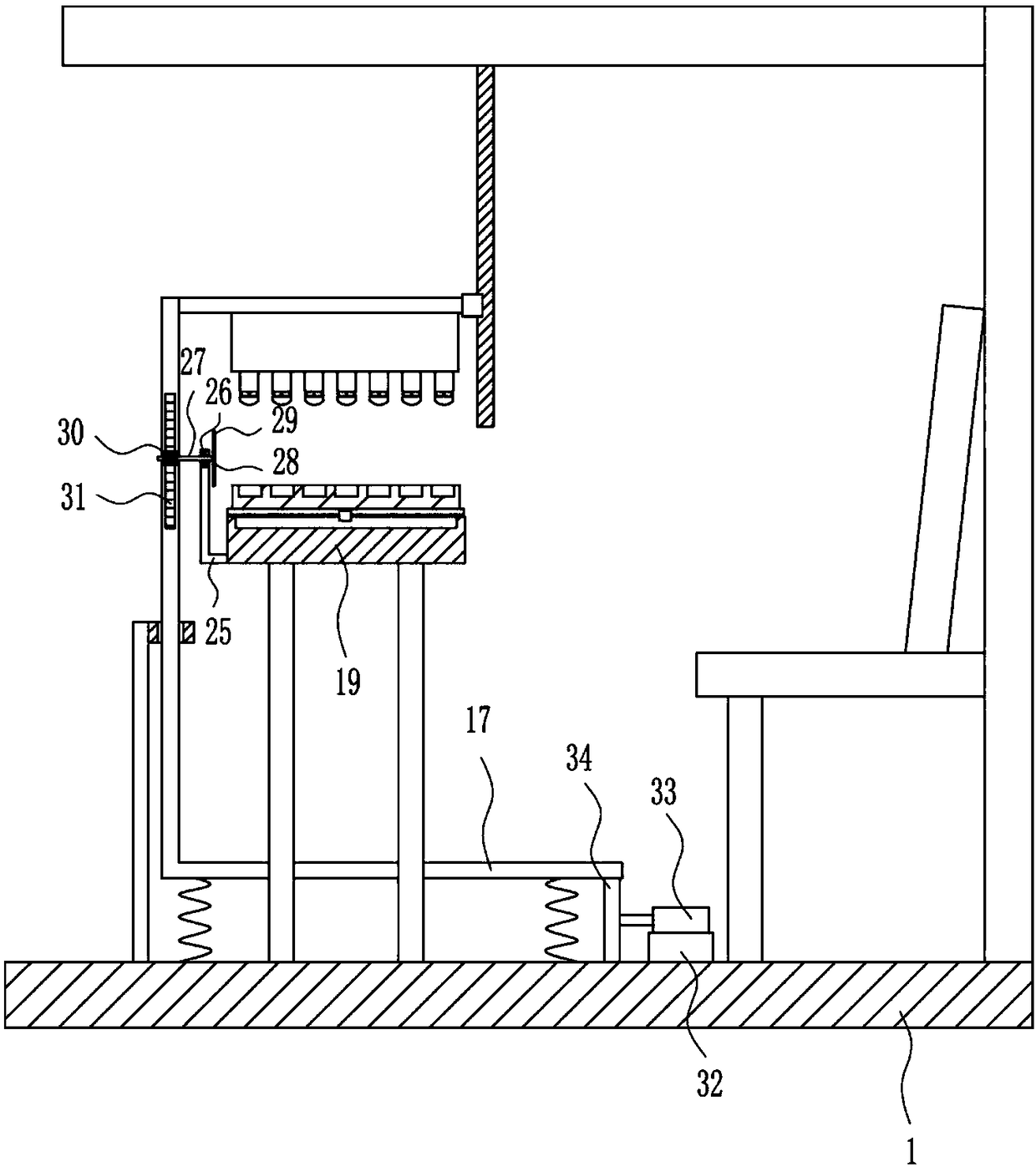

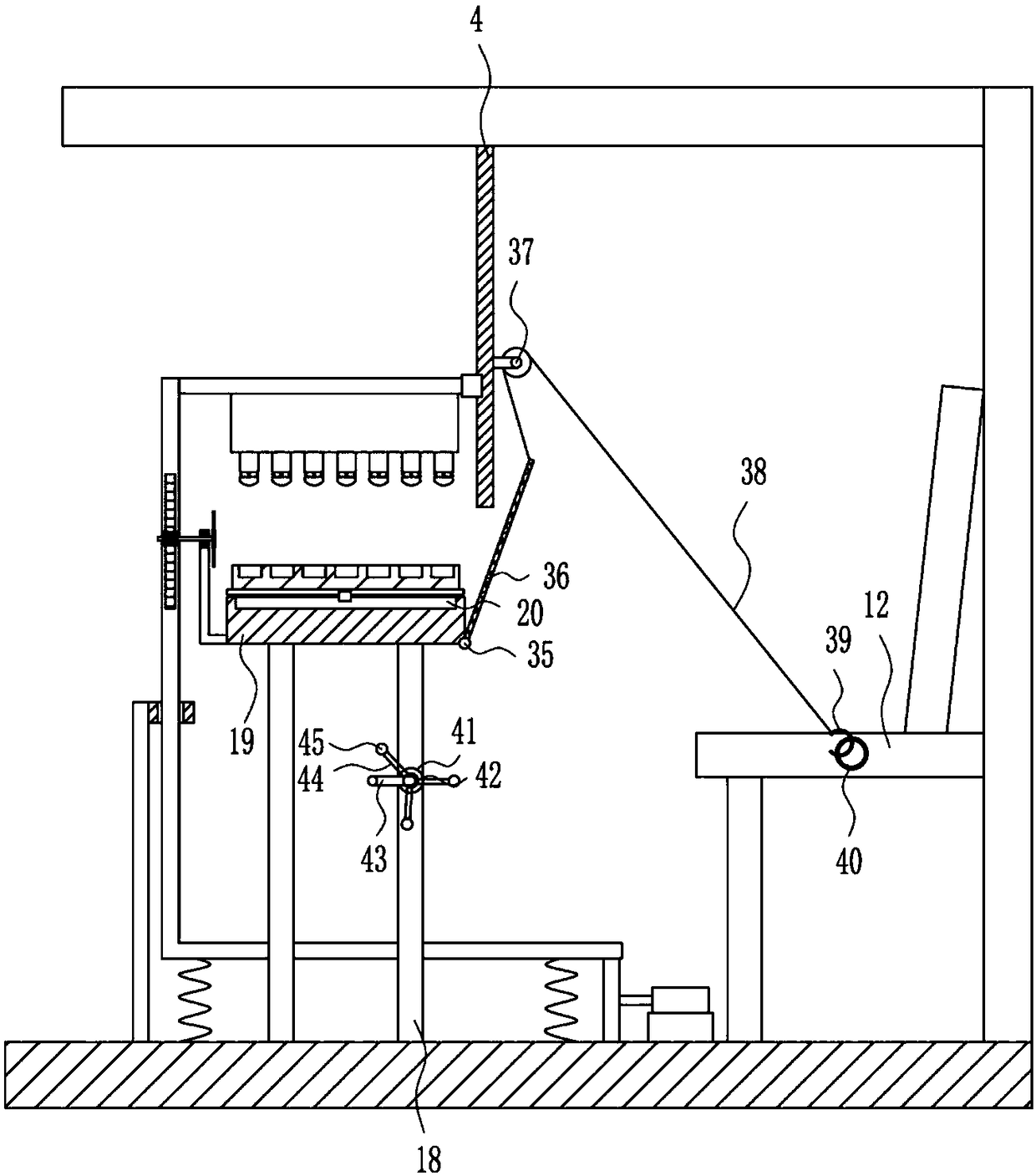

[0022] A food sunflower seed shelling equipment, such as Figure 1-3As shown, it includes a first mounting plate 1, a first support plate 2, a second support plate 3, a first slide rail 4, a first slider 5, a first moving rod 6, a second mounting plate 7, and a connecting rod 8 , the first spring 9, the rubber block 10, the installation rod 11, the seat plate 12, the backrest 13, the support rod 14, the sleeve 15, the second spring 16, the second moving rod 17, the first fixed rod 18, the console 19, The second slide rail 20, the second slide block 21, the moving plate 22 and the placement plate 23, the right side of the top of the first mounting plate 1 is connected with the first support plate 2, and the top of the first support plate 2 left side is connected with the first support plate 2. Two support plates 3, the middle of the bottom of the second support plate 3 is connected with a first slide rail 4, the first slide rail 4 is provided with a first slider 5, and the left...

Embodiment 2

[0024] A food sunflower seed shelling equipment, such as Figure 1-3 As shown, it includes a first mounting plate 1, a first support plate 2, a second support plate 3, a first slide rail 4, a first slider 5, a first moving rod 6, a second mounting plate 7, and a connecting rod 8 , the first spring 9, the rubber block 10, the installation rod 11, the seat plate 12, the backrest 13, the support rod 14, the sleeve 15, the second spring 16, the second moving rod 17, the first fixed rod 18, the console 19, The second slide rail 20, the second slide block 21, the moving plate 22 and the placement plate 23, the right side of the top of the first mounting plate 1 is connected with the first support plate 2, and the top of the first support plate 2 left side is connected with the first support plate 2. Two support plates 3, the middle of the bottom of the second support plate 3 is connected with a first slide rail 4, the first slide rail 4 is provided with a first slider 5, and the lef...

Embodiment 3

[0027] A food sunflower seed shelling equipment, such as Figure 1-3 As shown, it includes a first mounting plate 1, a first support plate 2, a second support plate 3, a first slide rail 4, a first slider 5, a first moving rod 6, a second mounting plate 7, and a connecting rod 8 , the first spring 9, the rubber block 10, the installation rod 11, the seat plate 12, the backrest 13, the support rod 14, the sleeve 15, the second spring 16, the second moving rod 17, the first fixed rod 18, the console 19, The second slide rail 20, the second slide block 21, the moving plate 22 and the placement plate 23, the right side of the top of the first mounting plate 1 is connected with the first support plate 2, and the top of the first support plate 2 left side is connected with the first support plate 2. Two support plates 3, the middle of the bottom of the second support plate 3 is connected with a first slide rail 4, the first slide rail 4 is provided with a first slider 5, and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com