Onion peeling method and peeling machine

A peeling machine and onion technology, applied in the fields of application, food processing, food science, etc., can solve the problems that workers can hardly tolerate onion blowing and cold blowing, increased processing costs, poor working environment, etc., and achieve the effect of peeling Good, save processing cost, simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

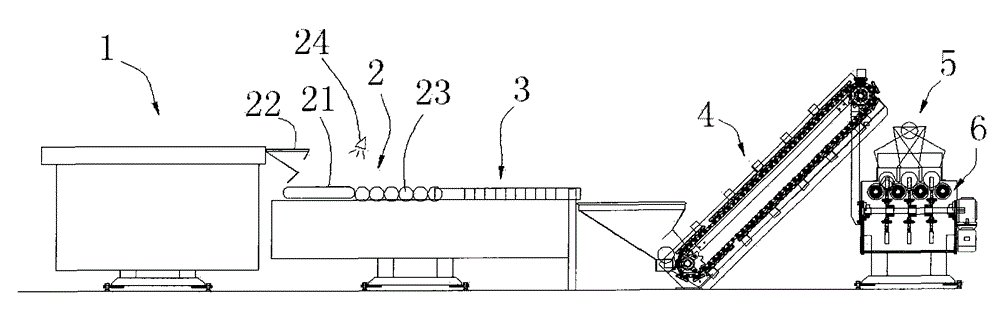

[0027] Example: see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a kind of onion peeling method, it is characterized in that, it comprises the following steps:

[0028] (1) Pour the onion on the feeding platform 1, and through the cleaning and conveying platform 2, the small pieces of garbage, soil clods, and extra small onions are leaked from the grid on the cleaning and conveying platform 2, and at the same time, it is cleaned manually or by a machine. Pick out larger garbage, clods, and moldy onions with your hands.

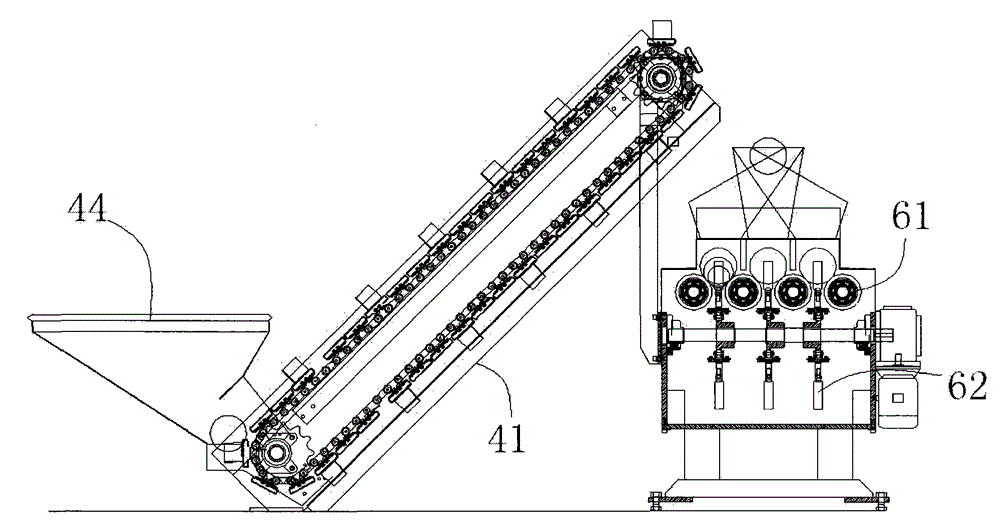

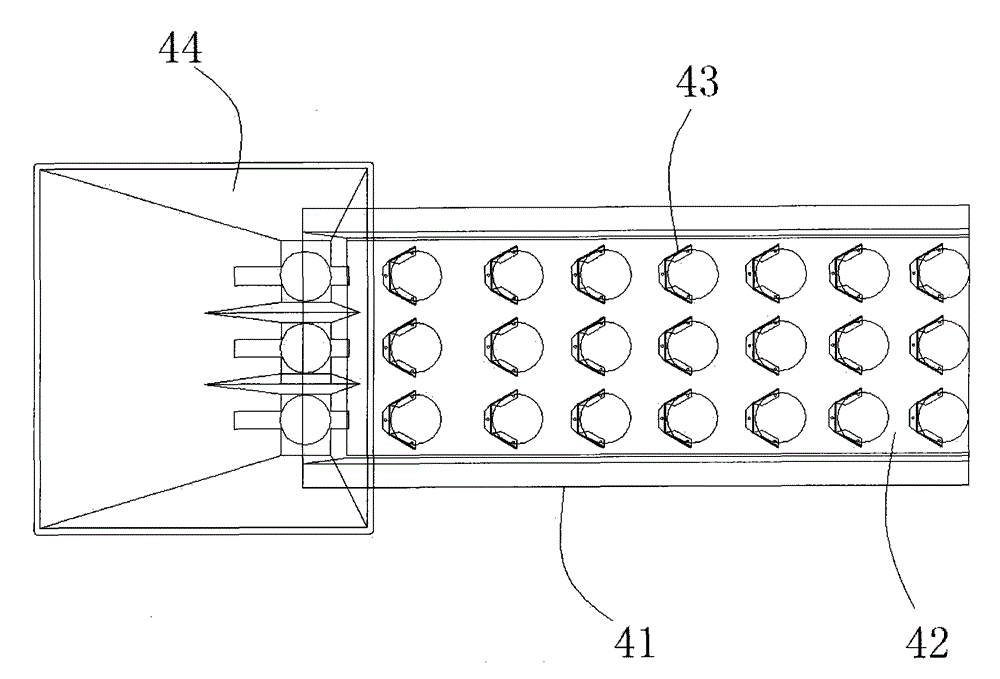

[0029] (2) The onions that have been preliminarily selected are transported to the grading and screening mechanism 3 by the cleaning and conveying platform 2, and the grading and screening mechanism 3 performs a screening process on the onions, removes the onions that do not meet the size, and then transports the onions that meet the requirements To the lifting conveyor 4; in the step (2), the grading and screening me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com