High-power-factor high-voltage non-stroboscopic LED linear drive circuit

A high power factor, linear drive technology, applied in the field of LED drive, can solve the problem that the traditional linear LED drive circuit cannot be flicker-free, and achieve the effect of high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

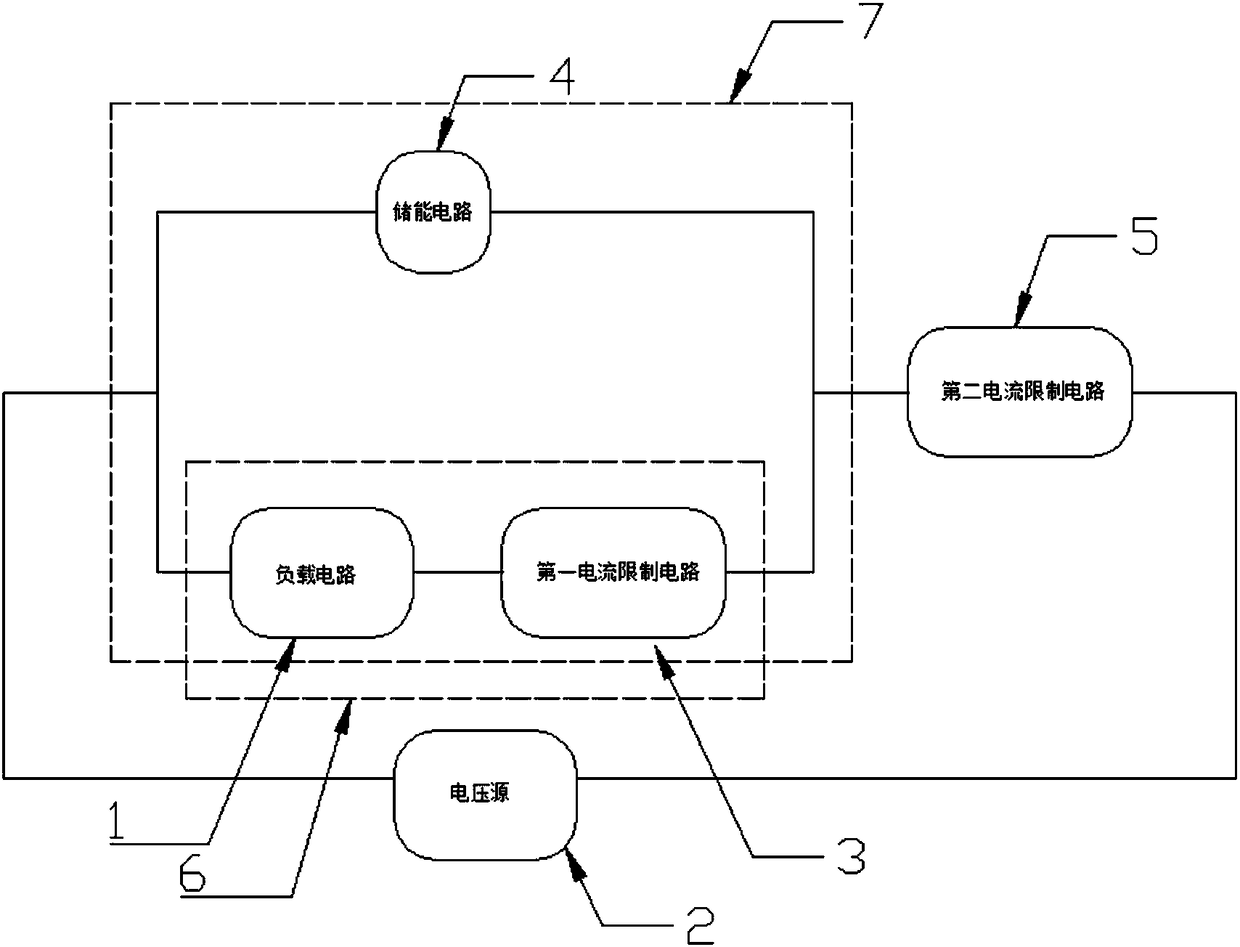

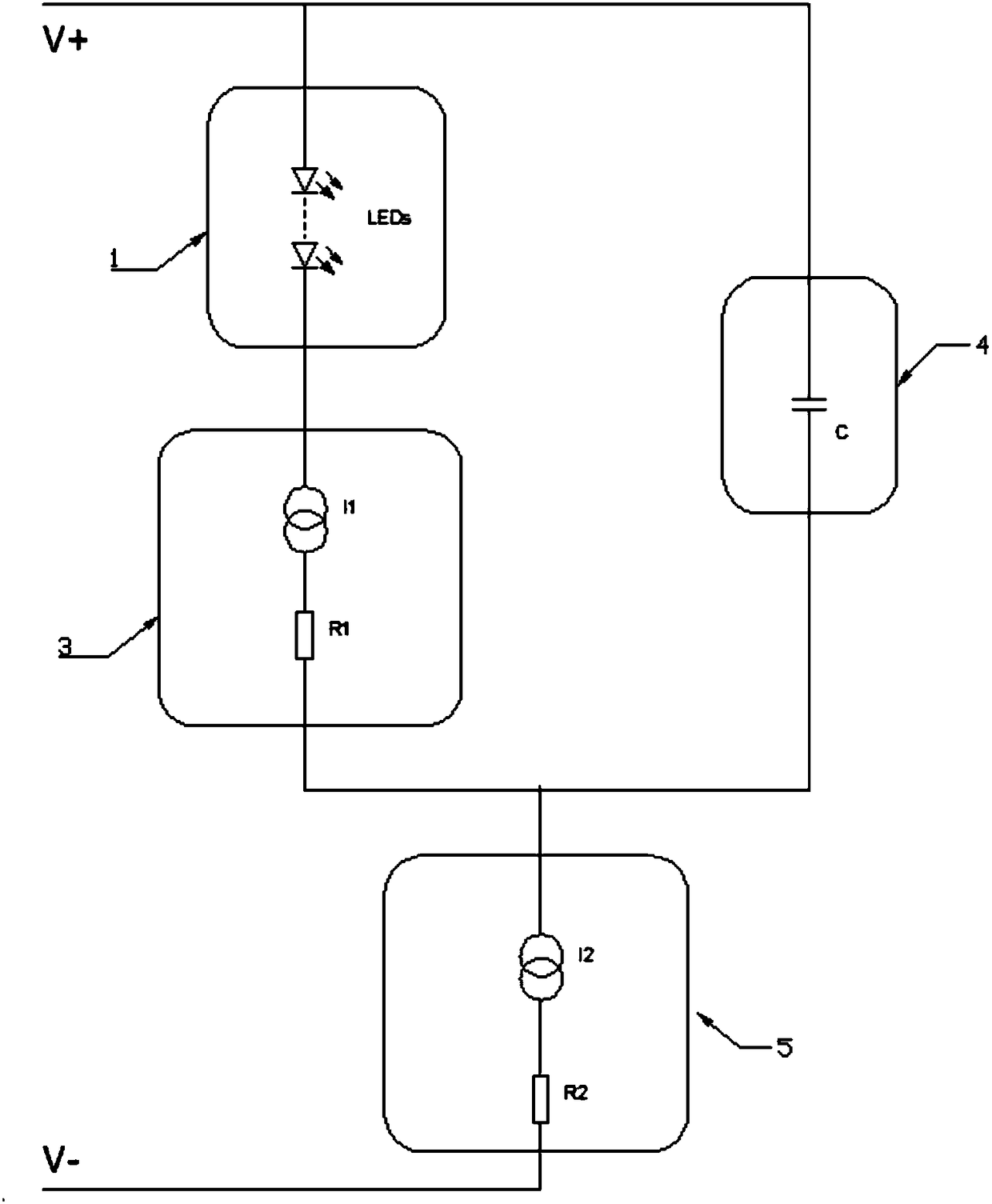

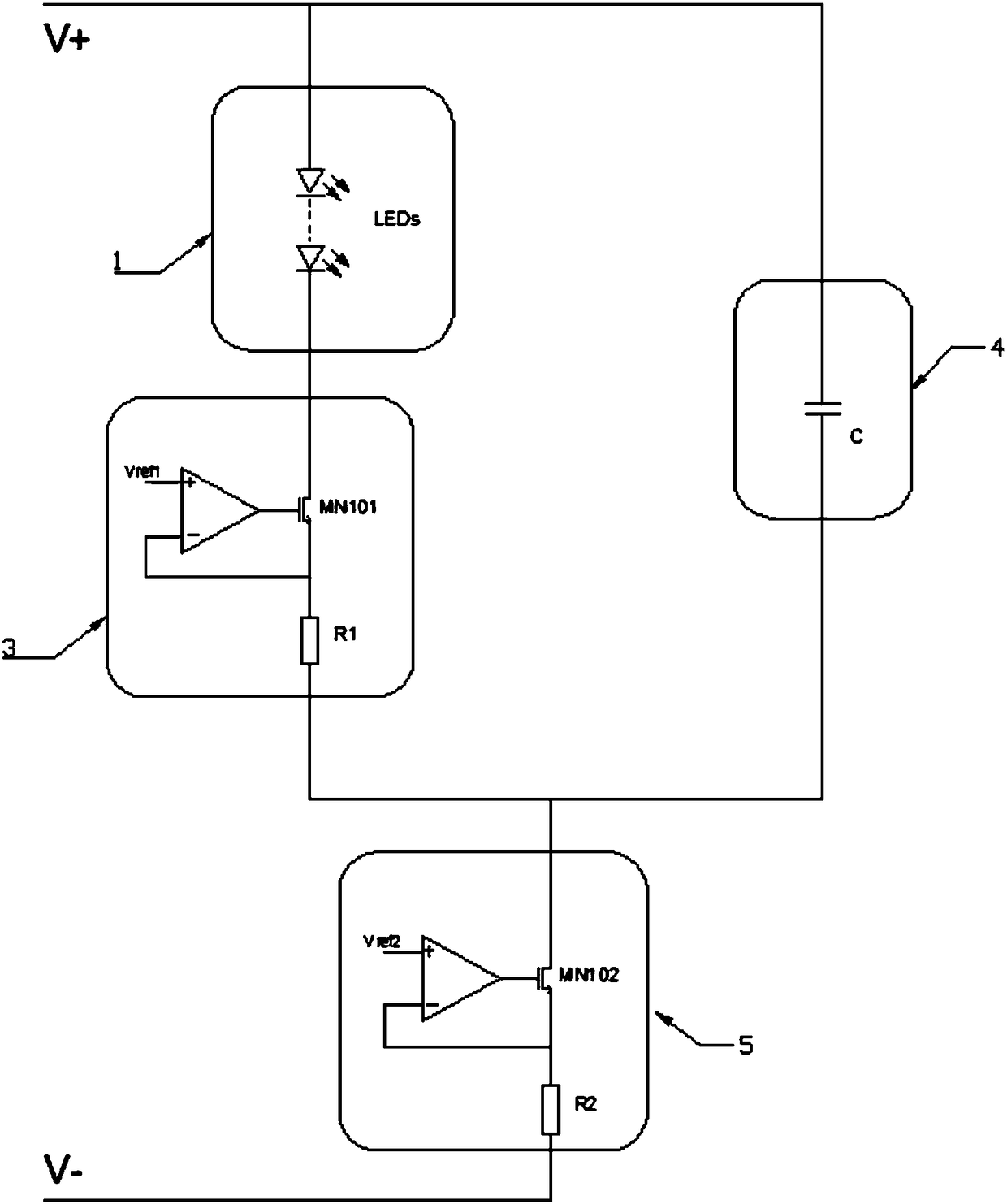

[0046] In order to achieve the purpose of the present invention, in some embodiments of a high power factor high-voltage flicker-free LED linear drive circuit, such as figure 1 As shown, a high power factor high-voltage flicker-free LED linear drive circuit includes:

[0047] A load circuit 1, including a plurality of LEDs connected in series;

[0048] Voltage source 2 for powering the LEDs;

[0049] The first current limiting circuit 3 is connected in series with the load circuit 1 to form a series module 6, the first current limiting circuit 3 is used to control the constant current flowing through the load circuit 1;

[0050] An energy storage circuit 4, which is connected in parallel with a series module 6 to form a parallel module 7, and the energy storage circuit 4 is used for storing electricity;

[0051] The second current limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com