Combined hoop for fixing cable

A combined, cable technology, applied in electrical components and other directions, can solve the problems of inability to meet various needs, poor corrosion resistance, easy to be stolen, etc., and achieve the effect of light weight, cost reduction and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

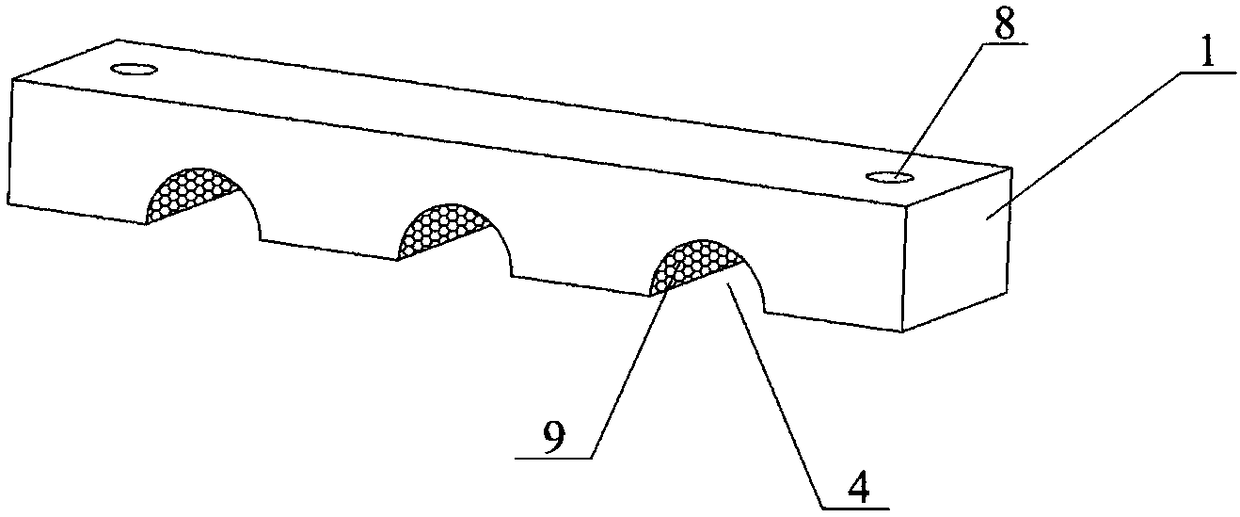

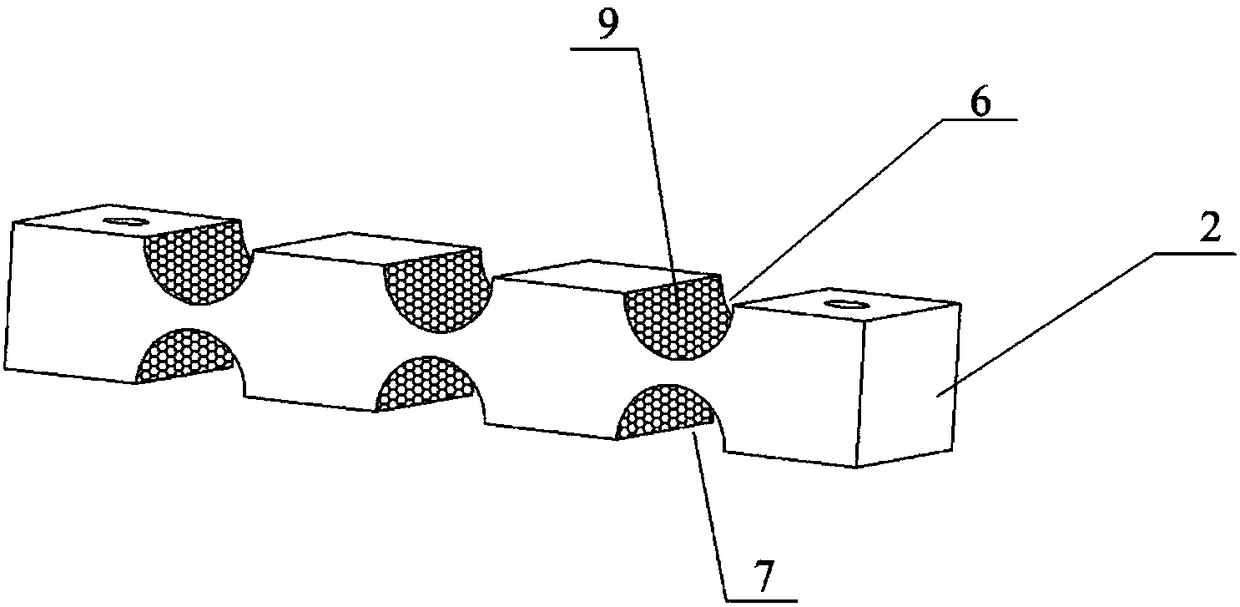

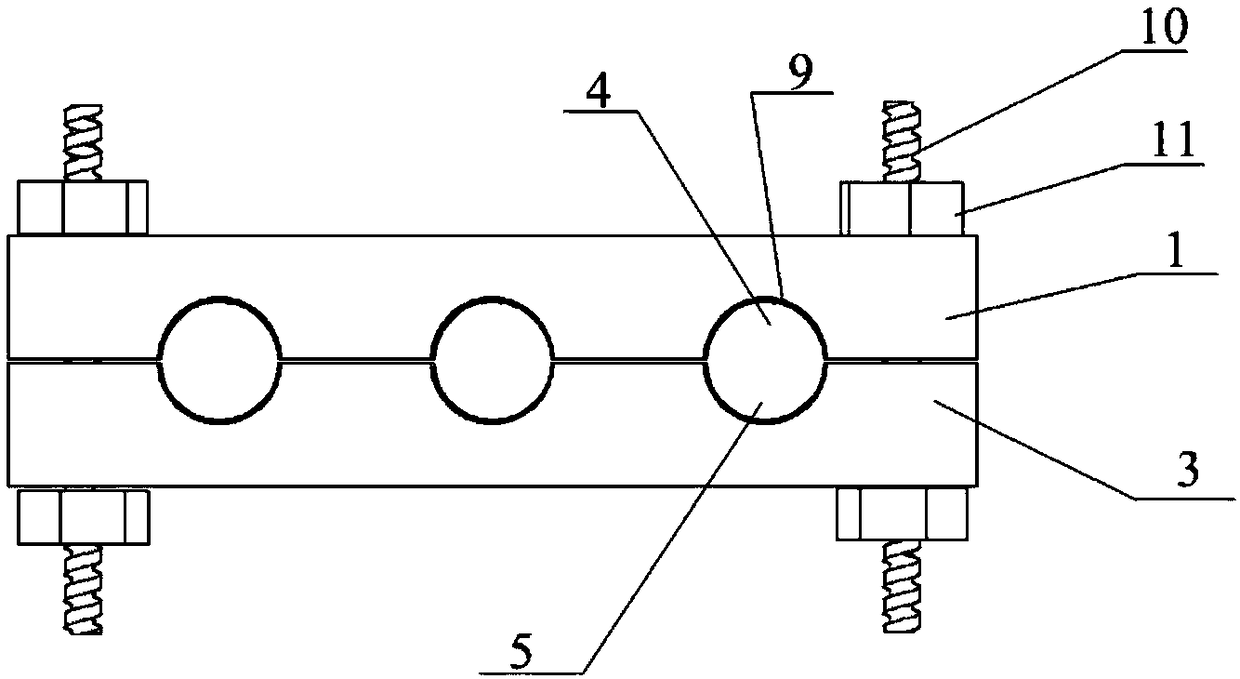

[0018] A combined hoop for fixing cables, including an upper hoop 1, a middle hoop 2, a lower hoop 3 and fasteners, the upper hoop 1, middle hoop 2 and lower hoop 3 are respectively integrated structure, the upper hoop 1, the middle hoop 2 and the lower hoop 3 are all cuboid in shape, wherein a first semicircular groove 4 is provided below the upper hoop 1, and a first semicircular groove 4 is provided above the lower hoop 3. The second semicircular groove 5, the top of the middle hoop 2 is provided with the third semicircular groove 6, the bottom of the middle hoop 2 is provided with the fourth semicircular groove 7, the first semicircular The size of the groove 4, the second semicircular groove 5, the third semicircular groove 6 and the fourth semicircular groove 7 is equal, and the upper hoop 1, the middle hoop 2 and the lower hoop 3 There are through holes 8 at the corresponding positions of the two ends, and the through holes 8 are matched with fasteners, and the upper ho...

Embodiment 2

[0024] A combined hoop for fixing cables, including an upper hoop 1, a middle hoop 2, a lower hoop 3 and fasteners, the upper hoop 1, middle hoop 2 and lower hoop 3 are respectively integrated structure, the upper hoop 1, the middle hoop 2 and the lower hoop 3 are all cuboid in shape, wherein a first semicircular groove 4 is provided below the upper hoop 1, and a first semicircular groove 4 is provided above the lower hoop 3. The second semicircular groove 5, the top of the middle hoop 2 is provided with the third semicircular groove 6, the bottom of the middle hoop 2 is provided with the fourth semicircular groove 7, the first semicircular The size of the groove 4, the second semicircular groove 5, the third semicircular groove 6 and the fourth semicircular groove 7 is equal, and the upper hoop 1, the middle hoop 2 and the lower hoop 3 There are through holes 8 at the corresponding positions of the two ends, and the through holes 8 are matched with fasteners, and the upper ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com