Maximum power tracking method for vehicle waste heat power generation system

A technology of maximum power tracking and thermal power generation system, which is applied in the direction of control/regulation system, regulation of electrical variables, instruments, etc., to achieve the effects of improving system efficiency, high-precision maximum power operation, and reducing oscillation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited thereto.

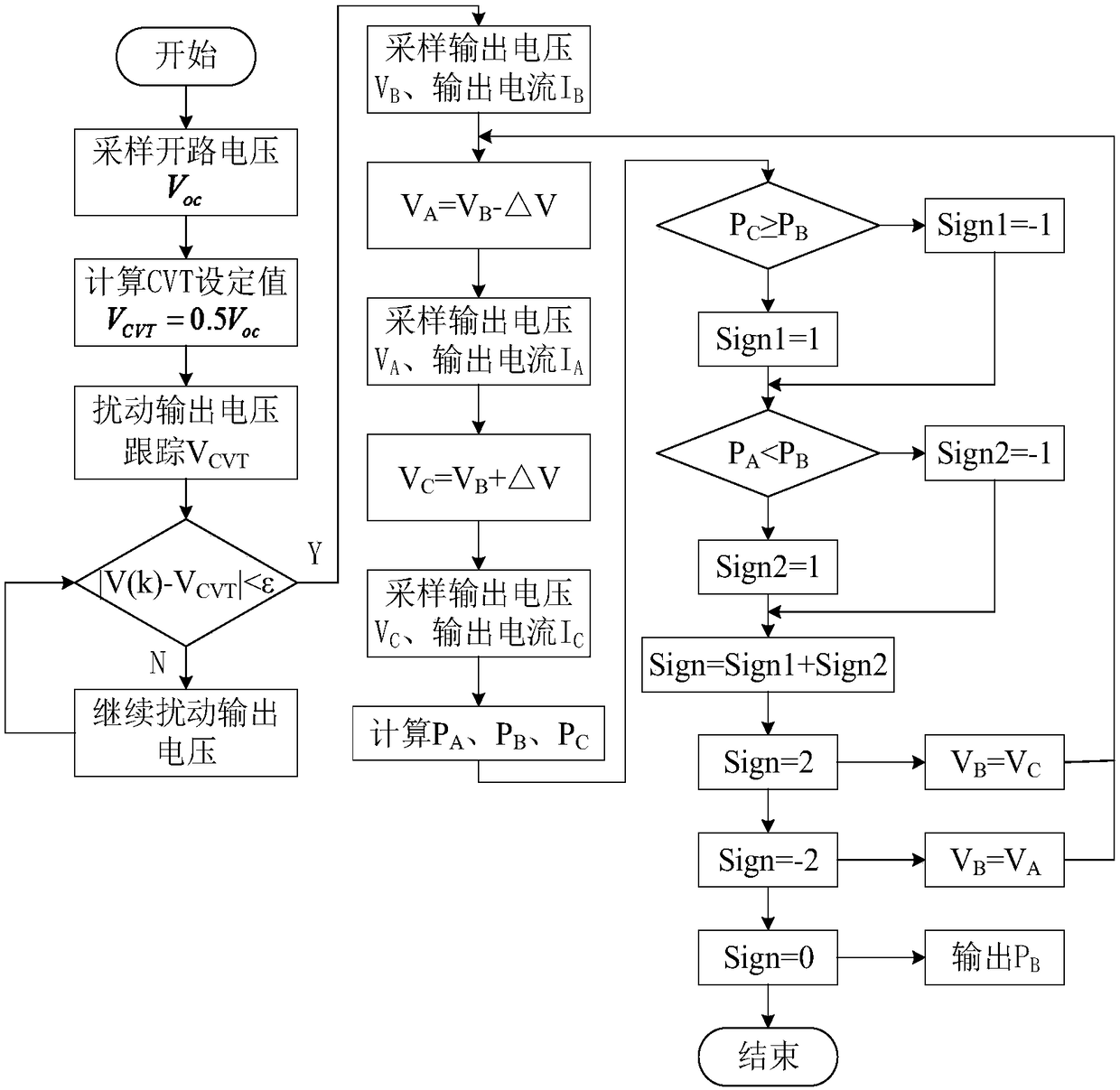

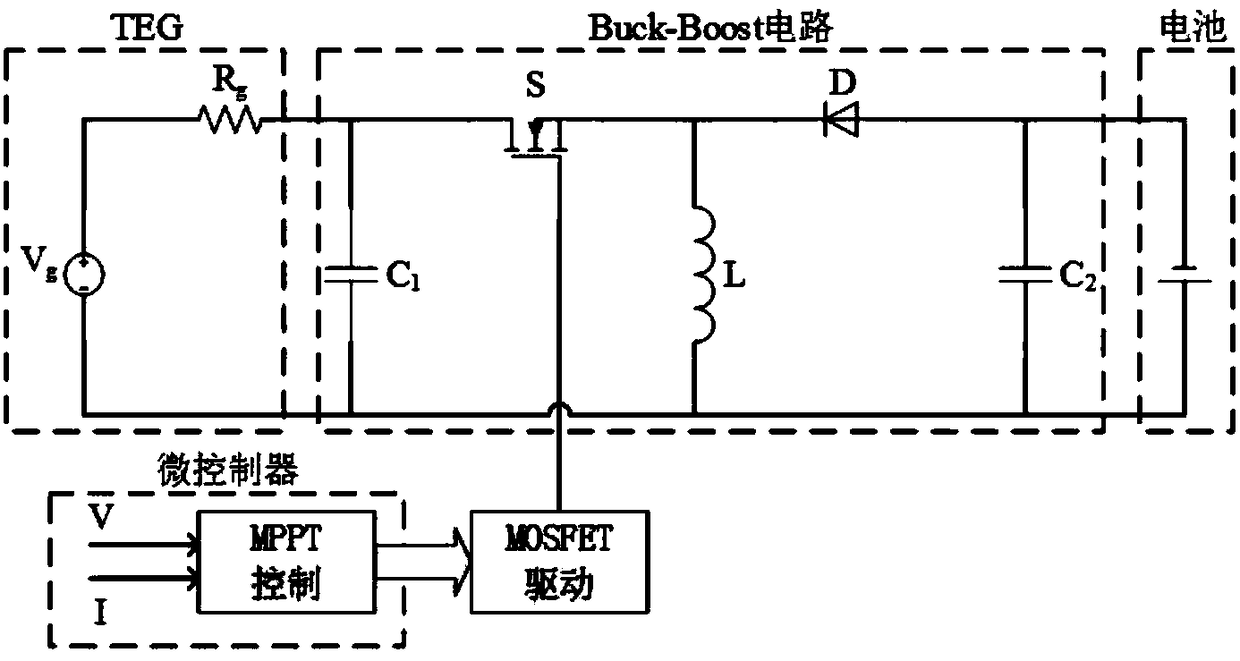

[0032] Such as figure 1 As shown, the maximum power tracking method of a vehicle waste heat power generation system designed in the present invention, the vehicle waste heat power generation system is a thermoelectric power generation system, which consists of a hot end (vehicle exhaust gas), a cold end (engine coolant or natural wind) and multiple The thermoelectric generators are connected in series and parallel. Follow the steps below:

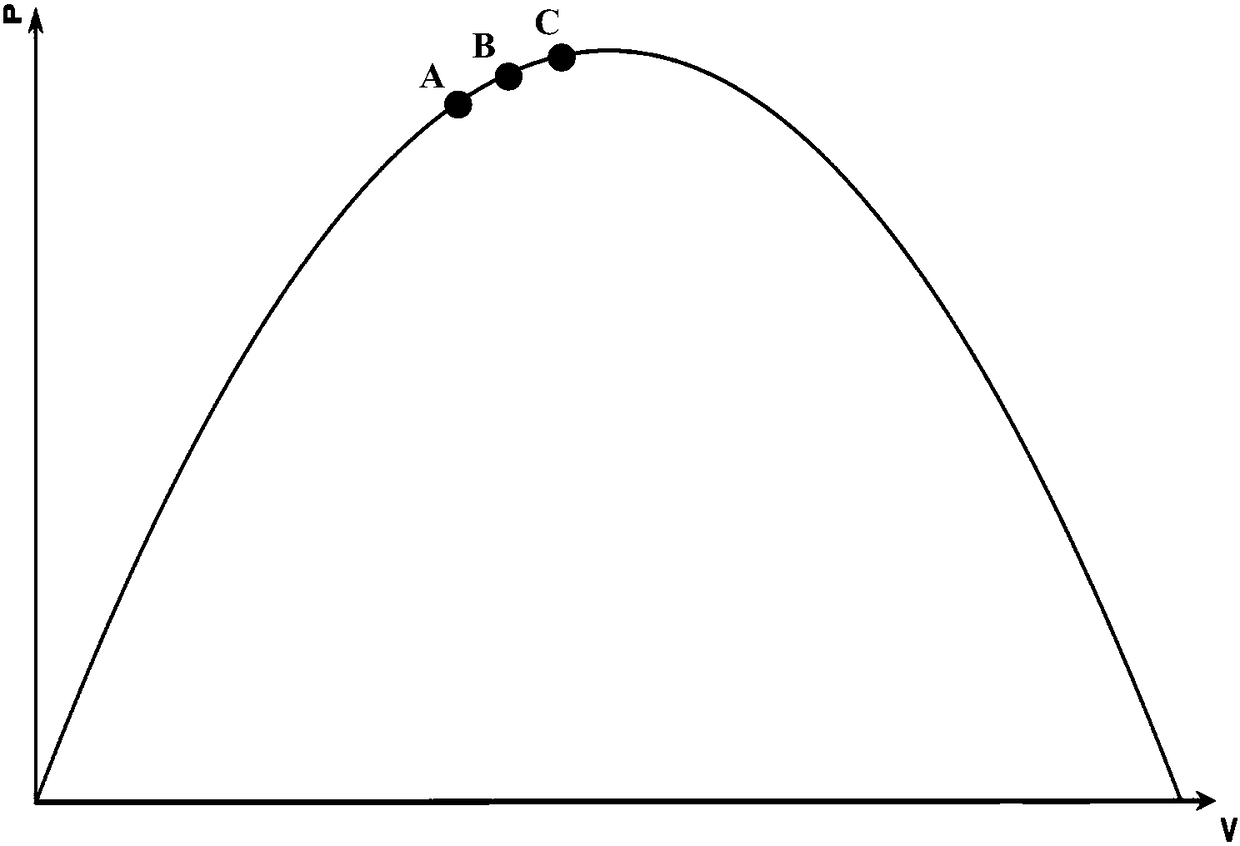

[0033] The maximum power tracking method combines the constant voltage method with the small-step hysteresis comparison method, and the open circuit voltage V of the thermoelectric module in the vehicle waste heat power generation system is oc When the external conditions change, the maximum power point voltage V of the thermoelectric module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com