Combine harvester online monitoring system

A technology of combine harvester and monitoring system, applied in general control system, control/regulation system, measuring device, etc., can solve the problems of irreparable, damaged, affecting the normal operation of combine harvester, etc., and achieve the effect of easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

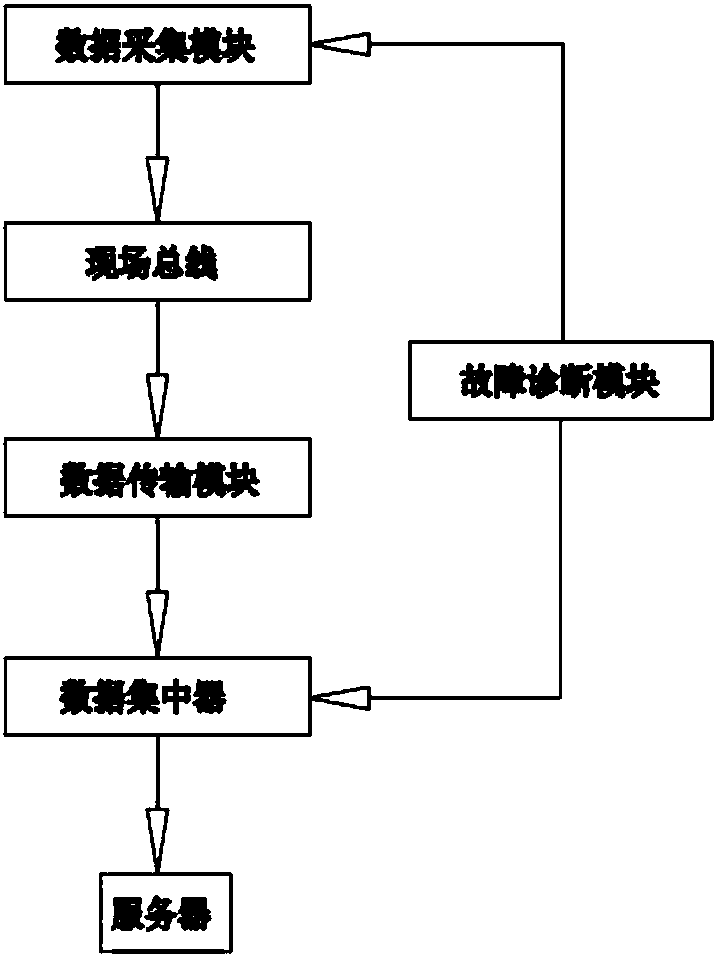

[0014] Such as figure 1 As shown, the present invention mainly includes a data acquisition module, a field bus, a fault diagnosis module, a data transmission module, a data concentrator and a server.

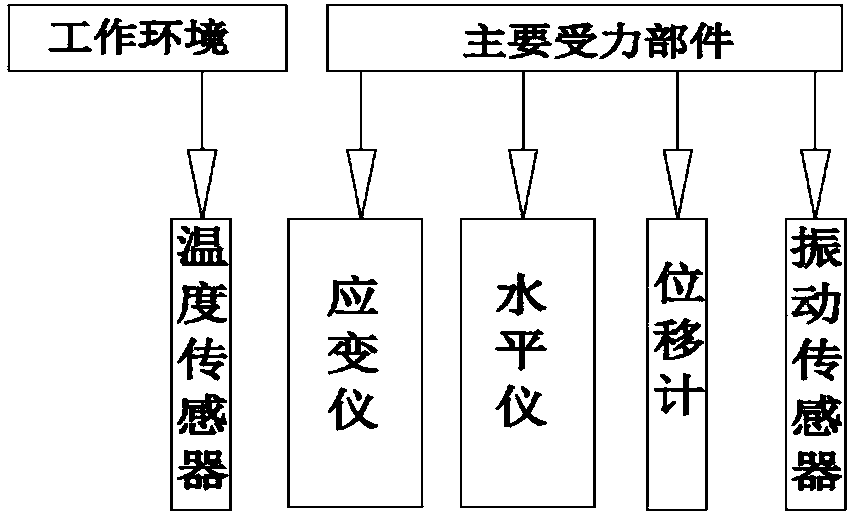

[0015] Such as image 3 As shown, the data acquisition module includes a strain sensor for monitoring the deflection of the main force-bearing parts of the combine harvester, a level meter for monitoring the inclination of the main force-bearing parts, a displacement meter for monitoring the relative deformation of the main force-bearing parts, and a sensor for monitoring the vibration of the main force-bearing parts. Vibration sensor, temperature sensor to monitor ambient temperature. The strain sensor monitors the deflection of the main stress-bearing parts, the level gauge monitors the inclination angle of the main stress-bearing parts, the displacement meter monitors the relative deformation of the main stress-bearing parts, and the vibration sensor monitors the vibration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com