Multi-scale soil-rock-mixture-bed rock interface shearing mechanical characteristic test device and method

A soil-rock mixture and testing device technology, applied in the direction of measuring device, strength characteristics, testing the strength of materials by applying a stable shear force, etc. The test device is simple, the operation is convenient, and the measurement accuracy is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The multi-scale soil-rock mixture-bedrock interface shear characteristic testing device in this embodiment includes a specimen system, a loading system, a balance control system, a servo control system and a data acquisition system, and the specimen system includes an upper rectangular tempered glass shear box 9. The lower rectangular steel shear box 18, soil-rock mixture sample 11, rock sample 19, antifriction lubricant 10, bedrock interface 33, loading plate 34, the upper rectangular tempered glass shear box 9 is composed of four It is composed of a transparent toughened glass plate and bolts. By changing the position of the bolts, the aspect ratio (1:1, 1.5:1 and 2:1) of the upper rectangular tempered glass shear box 9 can be changed, and the lower rectangular steel shear box 9 can be changed. Box 18 is made up of five steel plates and bolts, by changing the position of bolts, the aspect ratio of the lower rectangular steel shear box 18 corresponds to the aspect ratio...

Embodiment 2

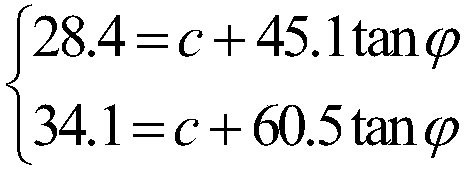

[0075] Consider bedrock interface morphology. The bedrock interface roughness coefficients of this example are J1=11.2 and J2=15.4 respectively.

[0076] 1) A rock sample with a certain bedrock interface roughness is processed by cutting in water. The size of the rock sample is 200mm×200mm×400mm, and the interface roughness coefficient is 15.4. Under this interface roughness coefficient, two identical size rock samples;

[0077] 2) Connect the front, rear, left, right and bottom five steel iron plates with bolts to form a lower rectangular steel shear box, and ensure that the aspect ratio of the lower rectangular steel shear box is equal to the length of the rock sample. The width ratio is consistent, which is then loaded into the lower rectangular steel shear box;

[0078] 3) Put the lower rectangular steel shear box and the rock test into the iron box as a whole, and make the centerlines of the three coincide with each other through the bolt, and then put the lower rectang...

Embodiment 3

[0094] Consider bedrock interface size effects. The aspect ratios of the bedrock interface in this example are l:d=1:1 and l:d=1:1.5, respectively.

[0095] Repeat steps 1) to 13), when l:d=1:1, the cohesive force of the bedrock interface is 16kPa, and the internal friction angle is 21°; when l:d=1:1.5, the cohesive force of the bedrock interface is 21kPa , the internal friction angle is 28°

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com