Electromagnetic reversing valve and valve body thereof

A technology of electromagnetic reversing valve and valve body, which is applied in the direction of valve details, multi-way valves, valve devices, etc., which can solve the problems of small amount of dirt contained, increased pollution of machine parts, and inconvenient assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

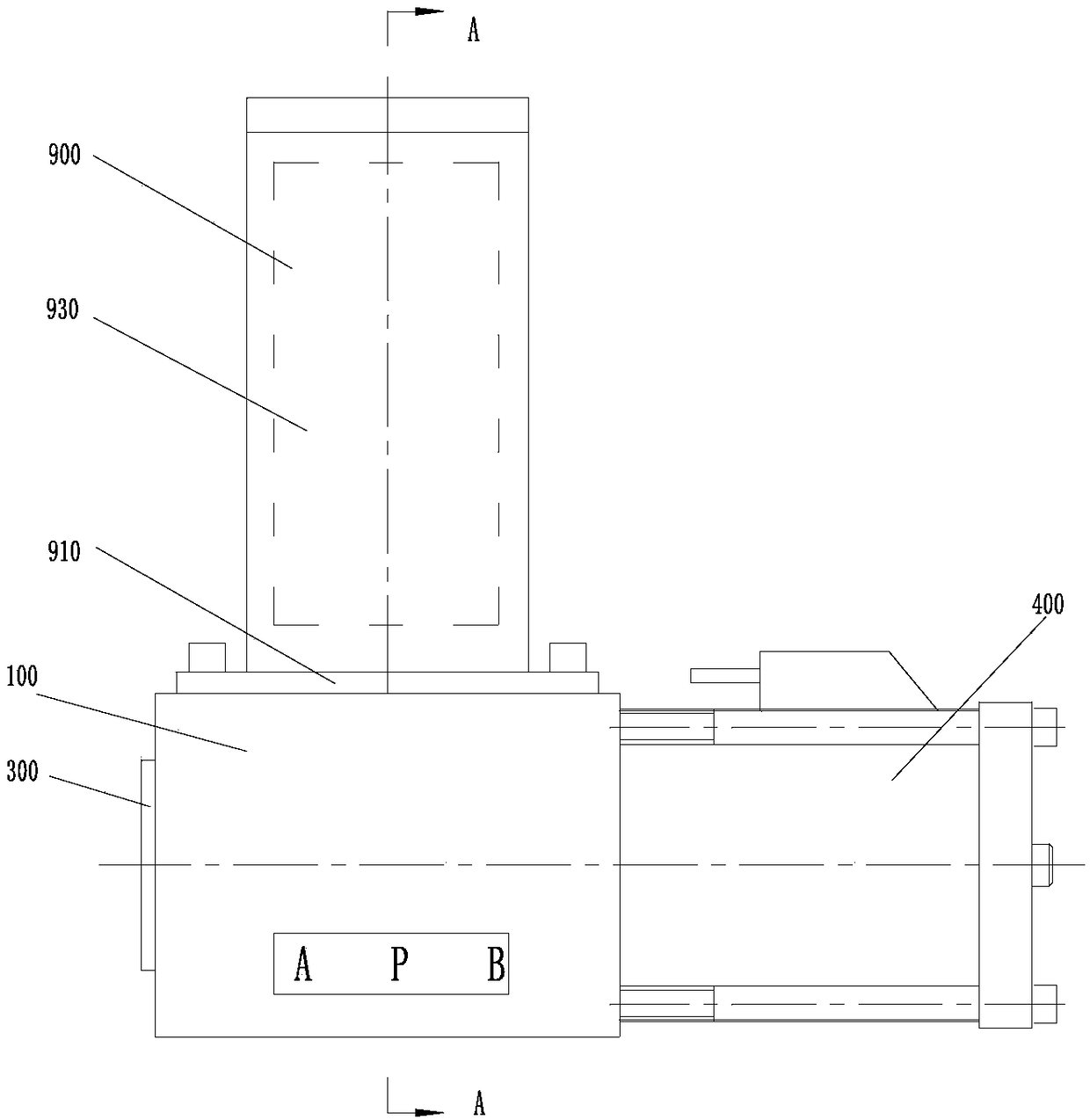

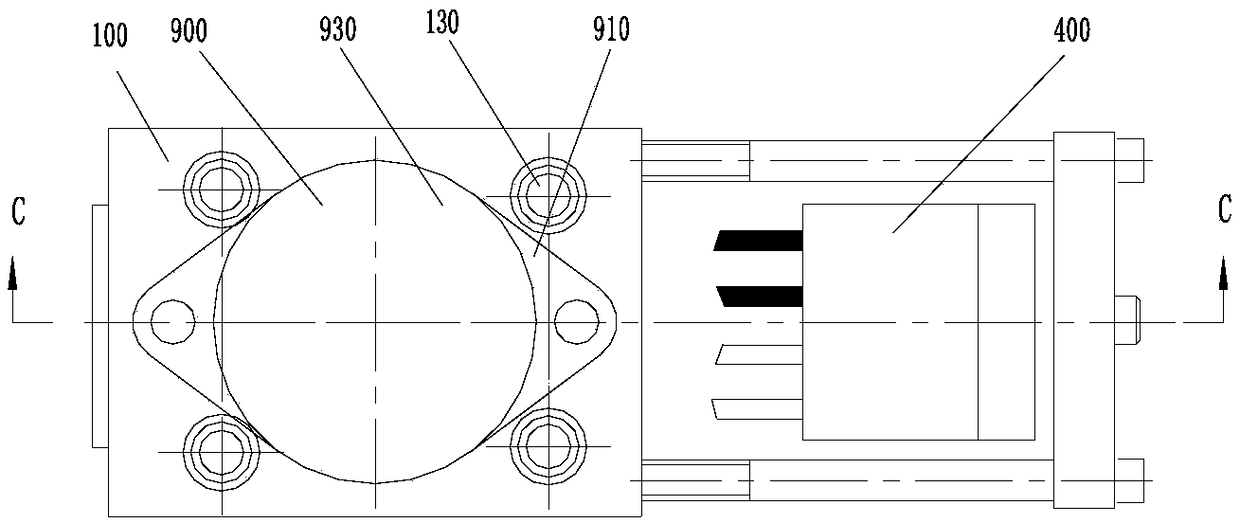

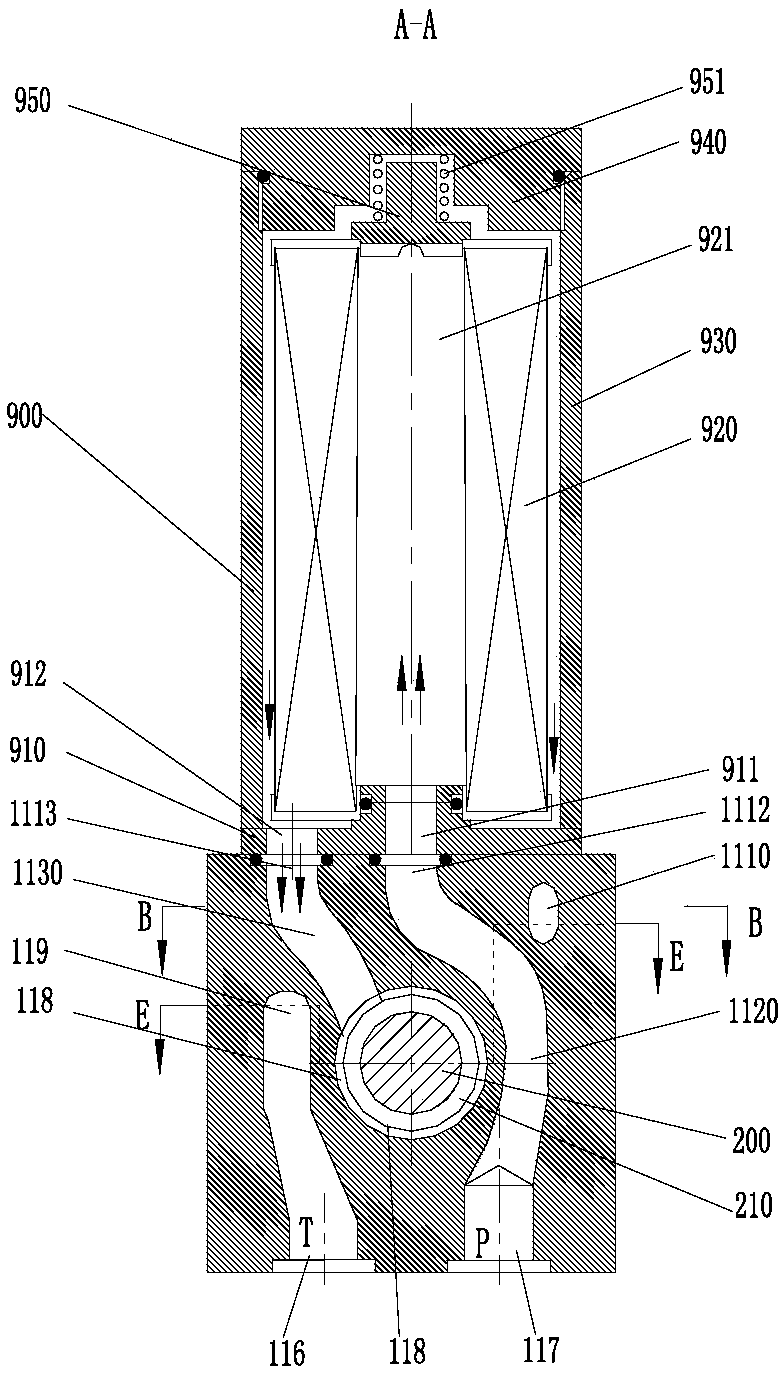

[0058] Such as Figure 1-12 As shown, a valve body 100 of an electromagnetic reversing valve, the valve body 100 includes a first oil port 114, a second oil port 115, an oil return port 116, an oil inlet 117 and a main hole of the valve body arranged along its axial direction 118, and the first oil passage 111, the second oil passage 112 and the third oil passage 113 arranged axially along the inner wall of the main hole 118 of the valve body, the first oil port 114 communicates with the first oil passage 111, the second The oil port 115 communicates with the third oil passage 113, and both the first oil passage 111 and the third oil passage 113 communicate with the main hole 118 of the valve body;

[0059] Such as Figure 7 As shown, the valve body 100 is provided with an oil return channel 119, the oil return port 116 is connected with the oil return channel 119, and the two ends of the oil return channel 119 are respectively located at the ends of the first oil channel 111...

Embodiment 2

[0067] Such as Figure 1-12 As shown, an electromagnetic reversing valve includes a valve body 100 , a valve core 200 , a valve body end cover 300 and an electromagnet assembly 400 .

[0068] Such as Figure 4 , 7 As shown, the valve body 100 includes a first oil port 114, a second oil port 115, an oil return port 116, an oil inlet port 117, and a main hole 118 of the valve body along its axial direction, and along the inner wall of the main hole 118 of the valve body The first oil passage 111, the second oil passage 112 and the third oil passage 113 are separately arranged in the upper axial direction, the first oil port 114 is connected with the first oil passage 111, and the second oil port 115 is connected with the third oil passage 113 The first oil passage 111 , the second oil passage 112 and the third oil passage 113 are all in communication with the main hole 118 of the valve body.

[0069] Such as Figure 7 As shown, the valve body 100 is provided with an oil retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com