In-situ protection of pressure pipelines crossing deep foundation pits and retaining structures and construction methods

A technology for retaining structures and deep foundation pits, which can be used in infrastructure engineering, excavation, construction, etc., to solve problems such as inability to meet on-site construction and failure to achieve reinforcement effects, and to reduce the possibility of water seepage, water leakage, landslides, and thickness reduction. , the effect of good piling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

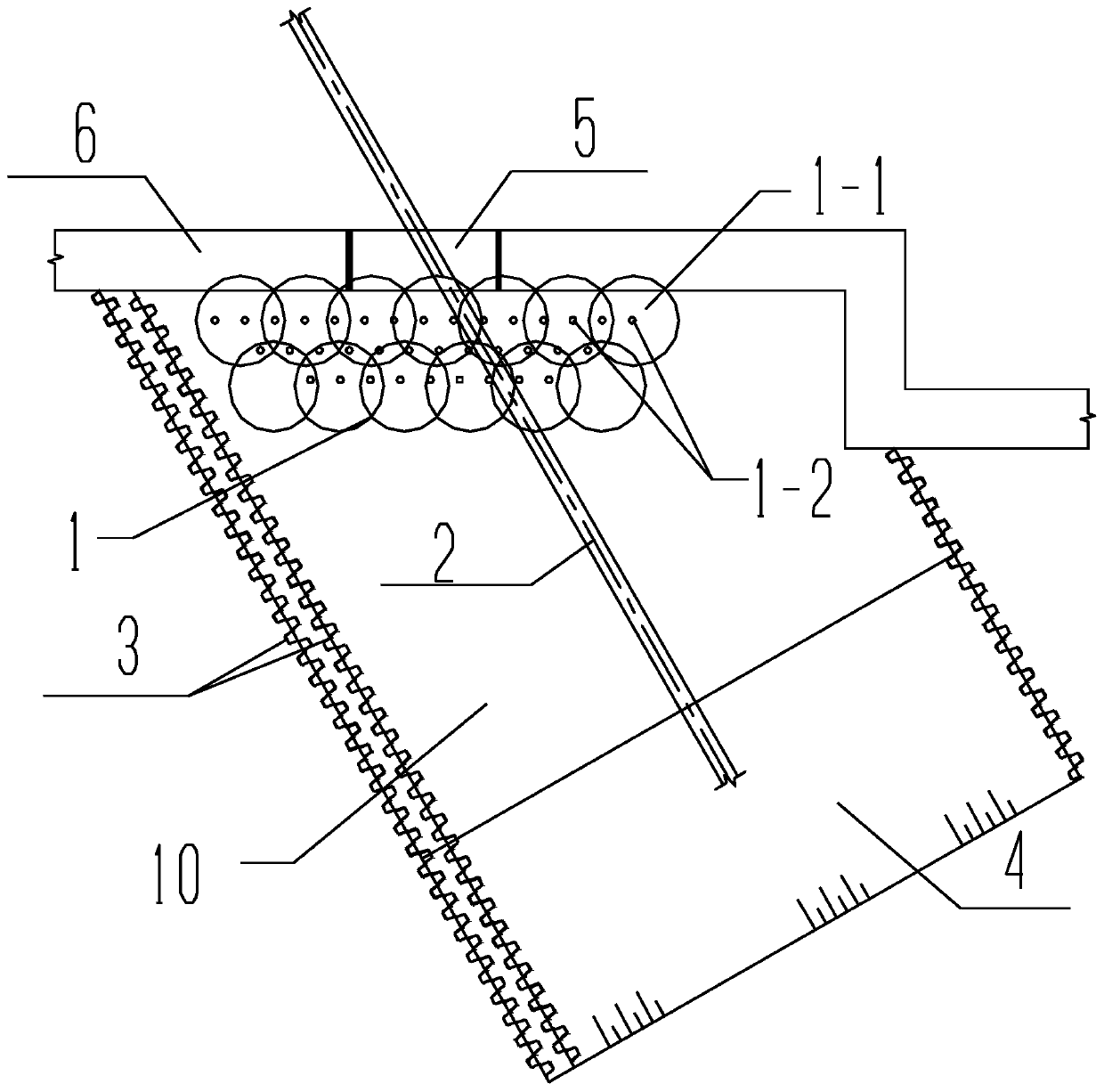

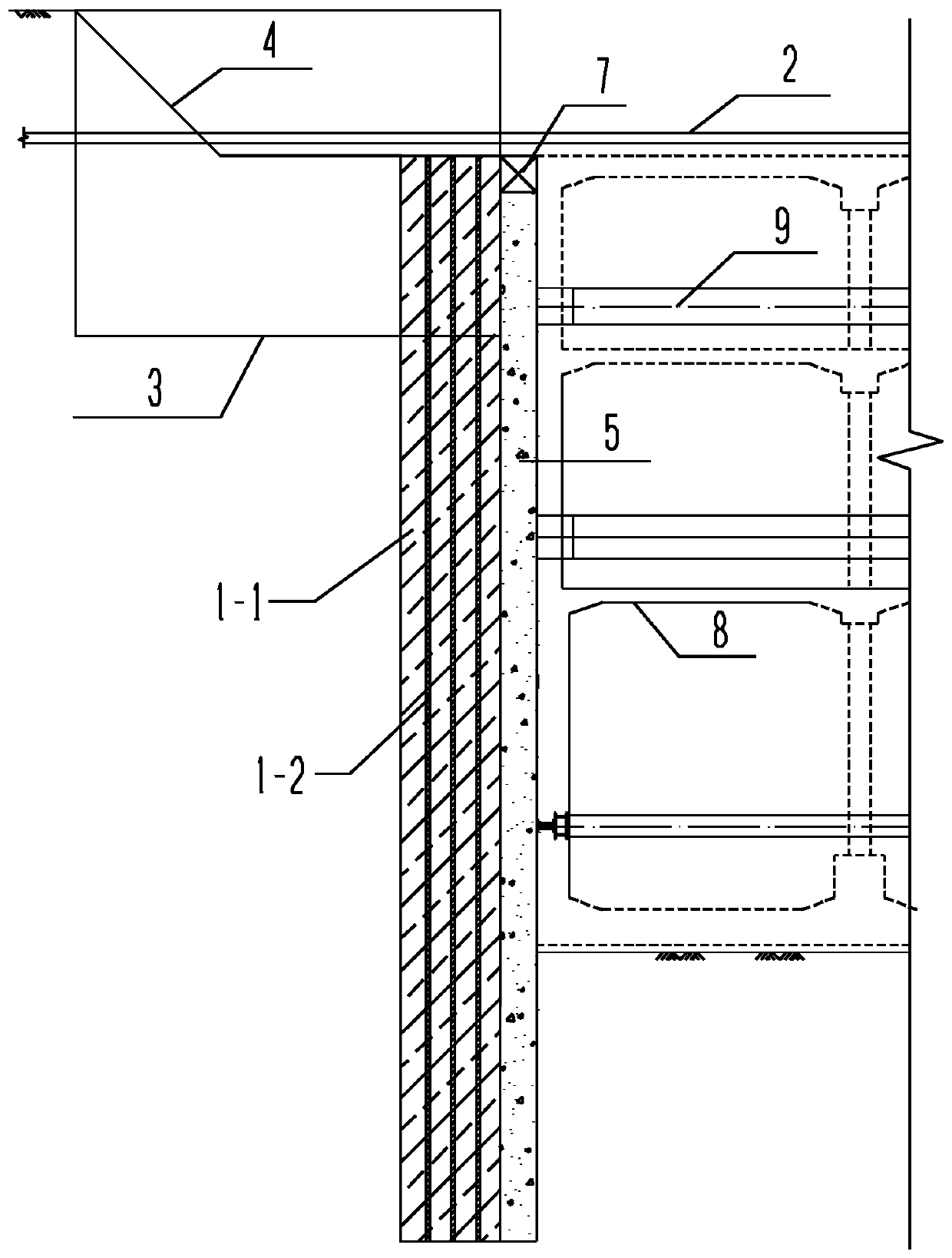

[0031] The present invention will be further described below in conjunction with drawings and embodiments. like figure 1A kind of in-situ protection and enclosure retaining structure for pressure pipelines crossing deep foundation pits shown, including the first-stage underground diaphragm wall 6 constructed on both sides of the in-situ protection pipeline 2, the first-stage underground diaphragm wall 6 An interruption area 5 is formed near the pipeline 2 to be protected in situ, the width of the interruption area 5 is not greater than 2.5m, and a gap greater than 0.5m is reserved between the two sections of the interruption area 5 and the pipeline 2 to be protected in situ, The underground diaphragm wall at the interrupted area is constructed by the reverse method. Before the construction, the retaining structure is constructed, and a retaining wall construction area 10 is dug outside the interrupted area 5. The width of the retaining wall construction area 10 is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com