Blade inclination angle adjustable and anti-slide abrasion-resisting reducing pitch adjusting detachable delivery pump screw shaft

A blade inclination and disassembly technology, applied in the field of machinery, can solve the problems of late discharge, increased power consumption, poor discharge, etc., to achieve the effect of convenient disassembly and maintenance, increase working life, and prevent material blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

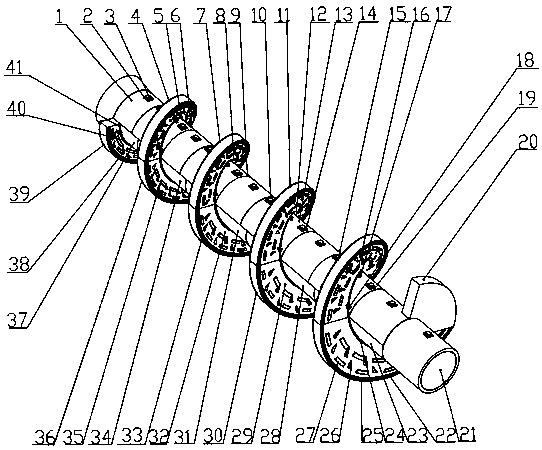

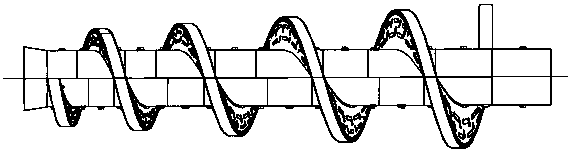

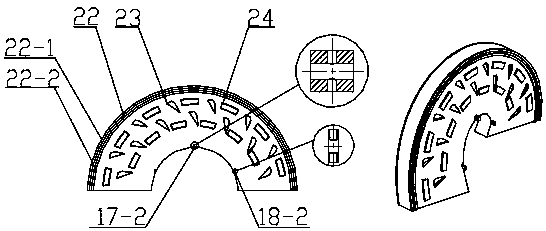

[0023] Such as Figure 1-Figure 7 As shown, a screw shaft of a detachable delivery pump with adjustable blade inclination and anti-skid and wear resistance is composed of nine different detachable blade components, a blade inclination adjustment structure, a blade positioning structure, a rotating shaft 21, and a tail end The baffle plate 20 and the filling plate 1 are composed; each detachable blade assembly is fixed on the corresponding position on the rotating shaft 21 through the blade positioning structure, and the blade inclination adjustment structure is installed on each detachable blade assembly, and the tail end baffle plate 20 Welded on the tail of the ninth detachable blade assembly 24, the filling plate 1 between each detachable blade assembly is connected on the rotating shaft 21 by screws 3; in this embodiment, there are 13 single Shaped crescent-shaped groove 26 and single-shaped arc-shaped protrusion 27, and the crescent-shaped groove 26 and arc-shaped protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com