Continuous multi-brick weighing and feeding device for refractory material

A technology of refractory materials and feeding devices, which is applied in the direction of unloading devices, conveyor control devices, transportation and packaging, etc. It can solve the problems of time-consuming and labor-intensive bricks, and it is difficult to carry bricks according to the predetermined weight, and achieve low manufacturing costs. The effect of fixed weight is good and the performance is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

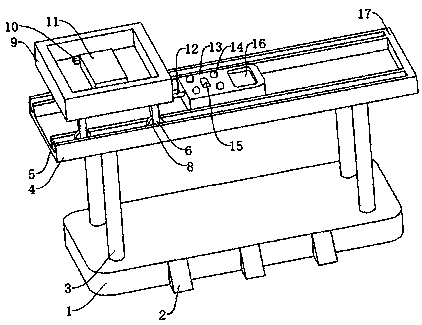

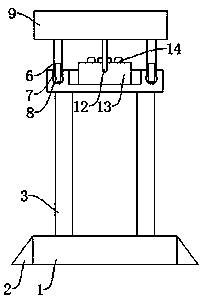

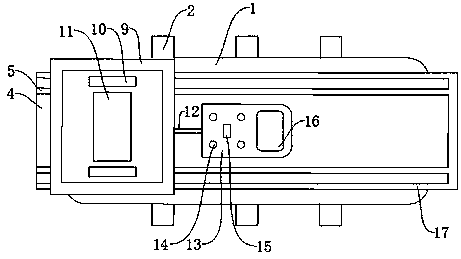

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1-Figure 3 As shown, a continuous multi-brick fixed-weight feeding device for refractory materials includes a fixed-weight feeder support 1, a pressure sensor 10, and an electric control box 13. The fixed-weight feeder support 1 is provided with ribs 2. To enhance the stability of the device, the fixed-weight feeder support 1 is provided with a fixed-weight feeder support 3 to support the slide table 4, and the upper end of the fixed-weight feeder support 3 is provided with a slide table 4. The upper end of the table 4 is provided with a chute 5 to provide a track for the movement of the load box 9. The upper end of the chute 5 is provided with a wheel support frame 6 to support the wheels 8. The wheel support frame 6 is provided with a wheel shaft 7, and the wheel shaft 7 is provided with There are wheels 8, and the upper end of the wheel support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com