A typical damage repair process of engine reverse thrust grille

A damage repair and engine technology, applied in the field of aircraft maintenance, to achieve the effect of expanding the scope of repair, clearing technical blind spots, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A typical damage repair process for an engine reverse thrust grille, comprising the following steps:

[0043] 1) Determine the typical damage types of the engine thrust reverser grille, including hyperboloid edge aperture damage and metal guide vane damage;

[0044] 2) For hyperboloid edge aperture damage, the repair methods include:

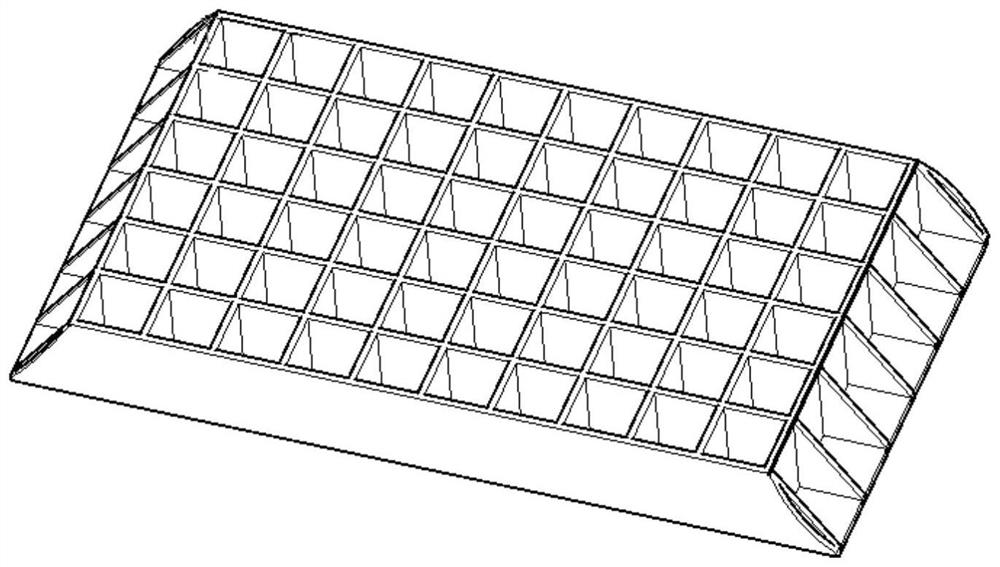

[0045] 2.1 The shape of the grid is kept in the grid near the hyperbolic edge aperture damage area. Set a separation film (not shown in the figure), and set a filler 1 (filler part number) in the separation film (part number of the separation film QZ5111). EC3524 B / A), such as figure 2 shown;

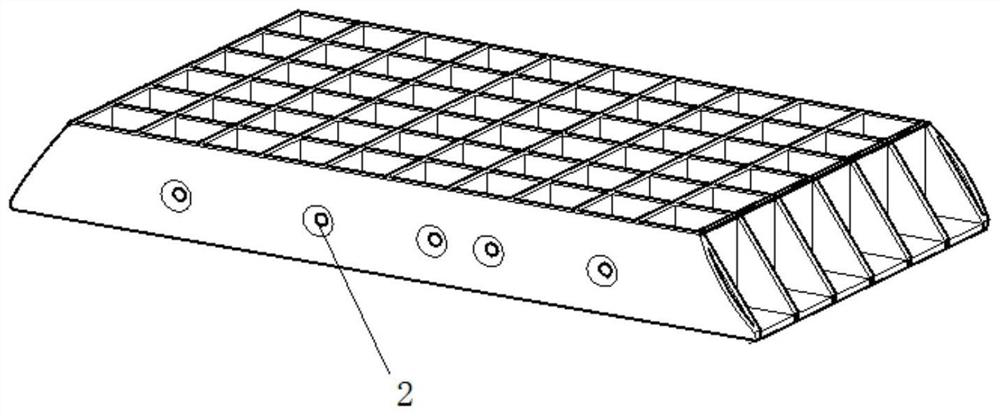

[0046] 2.2 Repair of the outer surface of the grid For the hyperboloid edge aperture damage area 2 Repair from the outer surface, such as image 3 As shown, the slope is firstly polished, and after the grinding is completed, the carbon fiber prepreg 3 is laid layer by layer from the outer surface of the hole damage area to the slope to form a f...

Embodiment 2

[0057] A typical damage repair process for an engine reverse thrust grille, comprising the following steps:

[0058] 1) Determine the typical damage types of the engine thrust reverser grille, including hyperboloid edge aperture damage and metal guide vane damage;

[0059] 2) For hyperboloid edge aperture damage, the repair methods include:

[0060] 2.1 The shape of the grid is kept in the grid near the hyperbolic edge aperture damage area, and the blue high-temperature separation tape is set in the grid, and the filling glue is set in the tape, such as figure 2 shown;

[0061] The blue tape is AIRIECH:Flashbreaker 1R, and the filling glue is EC3524 B / A.

[0062] The method of using blue tape and structural filling glue can ensure the strength of the filling structure and effectively prevent secondary damage to the original structure.

[0063] 2.2 The repair of the outer surface of the grille is repaired from the outer surface of the hyperboloid edge aperture damage area, ...

Embodiment 3

[0077] A typical damage repair process for an engine reverse thrust grille, comprising the following steps:

[0078] 1) It is determined that the typical damage type of the engine reverse thrust grid is the hyperboloid edge aperture damage;

[0079] 2) For hyperboloid edge aperture damage, the repair methods include:

[0080] 2.1 The shape of the grid is kept in the grid near the hyperbolic edge aperture damage area, and the blue high-temperature separation tape is set in the grid, and the filling glue is set in the tape, such as figure 2 shown;

[0081] The blue tape is AIRIECH:Flashbreaker 1R, and the filling glue is EC3524 B / A.

[0082] The method of using blue tape and structural filling glue can ensure the strength of the filling structure and effectively prevent secondary damage to the original structure.

[0083] 2.2 The repair of the outer surface of the grille is repaired from the outer surface of the hyperboloid edge aperture damage area, such as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com