Hub type rigid flange of rib-added composite foam sandwich barrel and preparation method thereof

A foam and reinforcement technology, which is applied in the field of new materials, new structures and combined structures, can solve the problem that the connecting flange of the composite foam sandwich tube cannot meet the large load-bearing requirements, the composite skin has weak supporting capacity, and the face core debonding fails and other problems, to achieve the effect of superior surface-core bonding strength, high-efficiency play of strength, and high surface-core bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

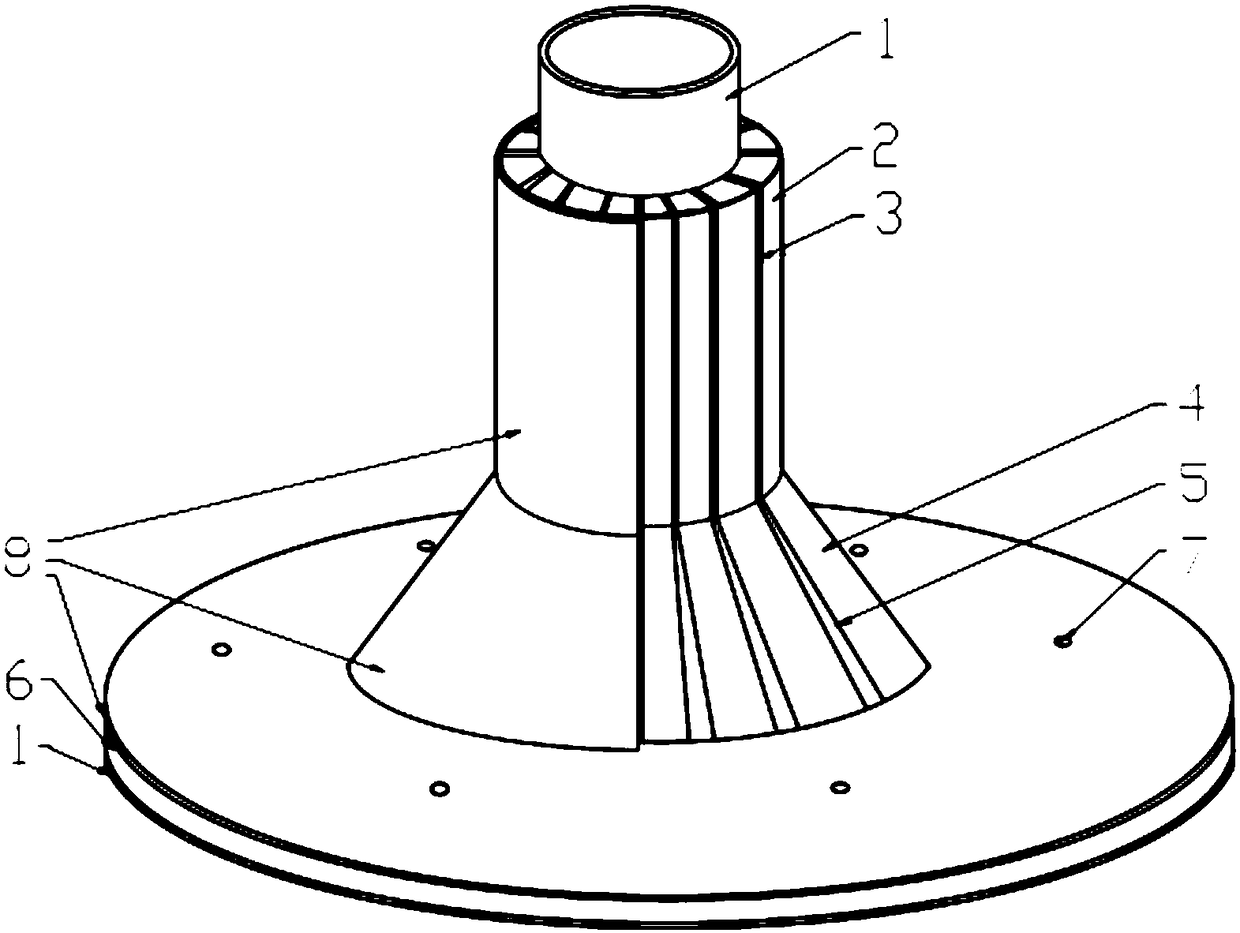

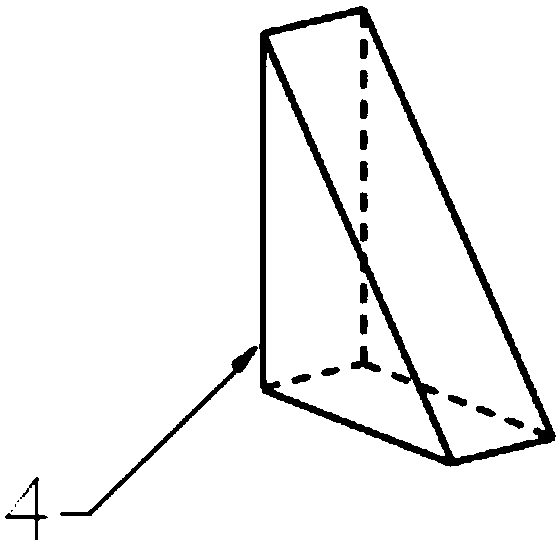

[0031] This embodiment provides a rigid flange with a neck of a reinforced composite foam sandwich tube, the structure of which is as follows figure 1 As shown, the main body of the necked rigid flange includes a neck, a support part and a flange part. Ring-shaped structure, one end of the neck is connected to the smaller end of the support part, and the larger end of the support part is connected to the flange part; a connecting flange is provided at one end of the foam sandwich tube for connection with another necked rigid method The flanges are connected, and steel plates are added in the middle of the flange; the neck includes composite material inner skin 1 and composite material outer skin 8, and vertical foam slats 2 are evenly distributed between the composite material inner skin 1 and composite material outer skin 8 Composite strip reinforcement 3, the composite strip reinforcement 3 is equally spaced between the vertical foam slats 2, the composite interior skin 1 an...

Embodiment 2

[0041] This embodiment provides a method for preparing a rigid flange with a neck of a reinforced composite foam sandwich tube, which consists of a composite material inner skin, a composite material outer skin, foam sandwiched between two skins, foam It is composed of composite material ribs between the two skins; the height of the reinforced composite foam sandwich tube is 1000mm, and the inner diameter is 200mm; the composite material inner skin and the composite material outer skin are reinforced by glass fiber biaxial cloth Composed of resin-based composite materials, the thickness is 3mm; the foam material has a density of 100kg / m 3 PVC foam with a thickness of 40mm; the composite ribs are made of glass fiber unidirectional cloth reinforced resin-based composites.

[0042] Including the following specific steps:

[0043] (1) Prepare PVC foam: According to the design requirements of component size, PVC foam is provided by Beijing Colas Co., Ltd., with a density of 100kg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com