Manufacturing technique of rigid magnetic yoke of motor rotor of large pumped storage generator

A technology of pumped storage and manufacturing process, which is applied in the manufacture of motor generators, electromechanical devices, electric components, etc., to achieve the effect of improving position, ensuring processing quality, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

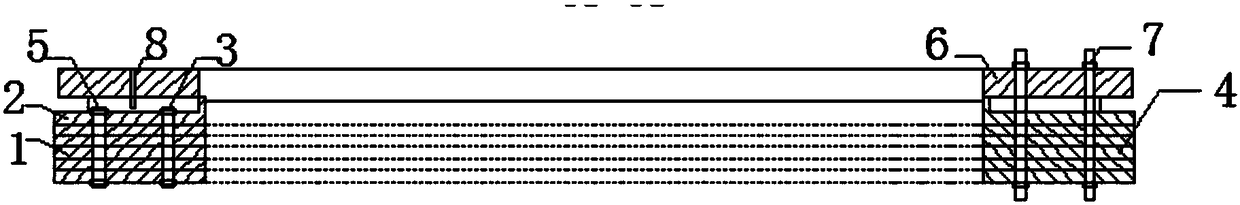

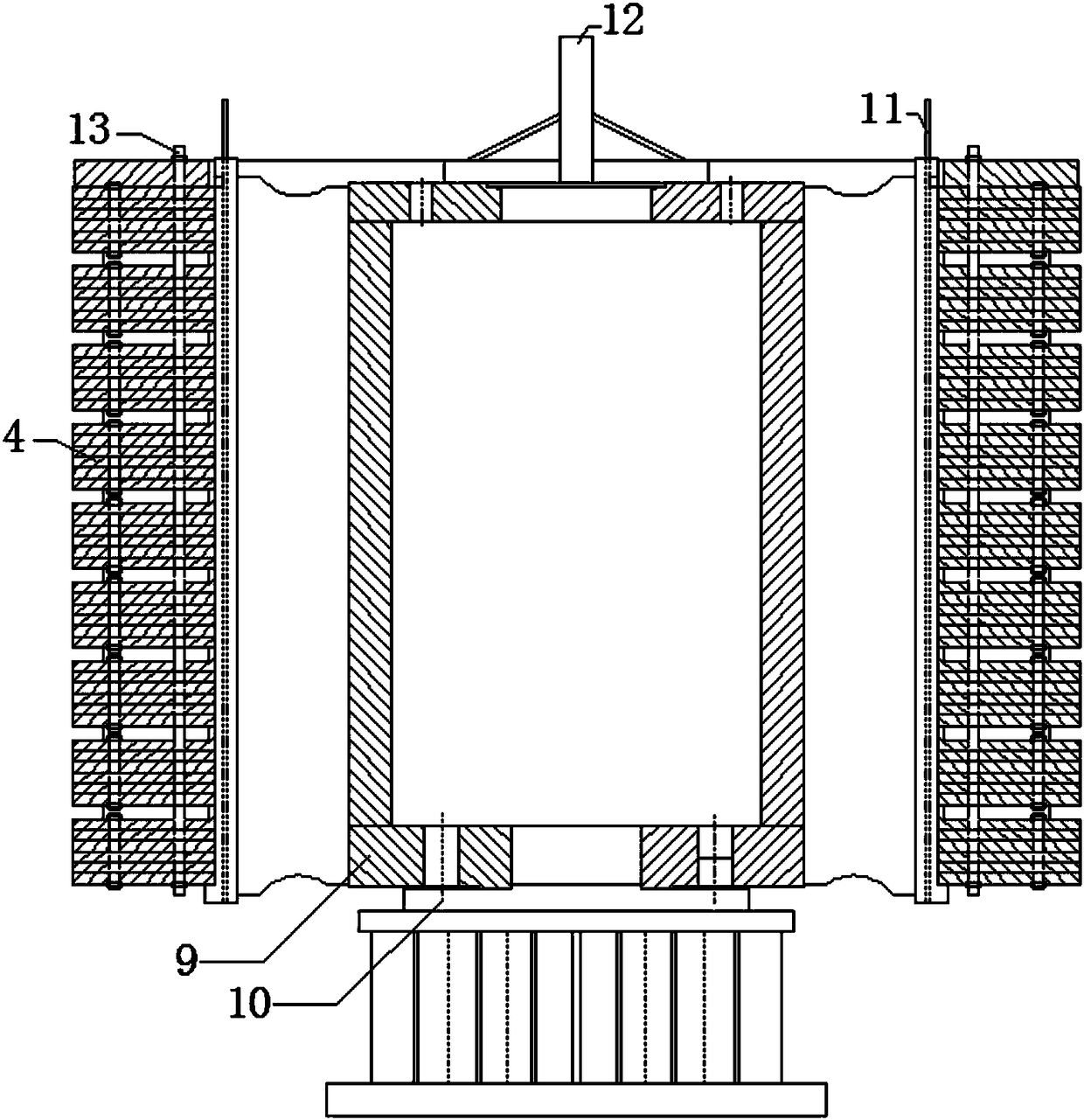

[0035] Such as figure 1 , figure 2 As shown, the present invention is a manufacturing process for the rigid yoke of a large-scale pumped storage generator motor, which ensures the processing quality of the rigid yoke while shortening the production cycle, high production efficiency and high manufacturing precision. Technical scheme of the present invention is:

[0036] 1) The upper and lower planes of the single disc 1 are processed by CNC turning and boring integrated vertical lathe, and the thickness meets the requirements of the drawing; the inner and outer circles of the rough car are left 2mm on one side; when the station remains unchanged, the 56-φ36mm The positioning pin hole and the 28-φ40mm screw hole are all pre-drilled to φ32mm.

[0037] 2) Use the vertical lathe to finish the upper and lower planes of the air guide disc 2 to meet the requirements of the drawings; to finish the inner and outer circles, leave a margin of 2mm on one side.

[0038] 3) Use fifty-six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com