Single layer type sock shoe and production method thereof

A production method, single-layer technology, applied in footwear, clothing, textiles and papermaking, etc., can solve the problems of increasing manufacturer expenditure, increasing manufacturer production expenditure, and single product, so as to save equipment purchase expenditure and improve competitiveness , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

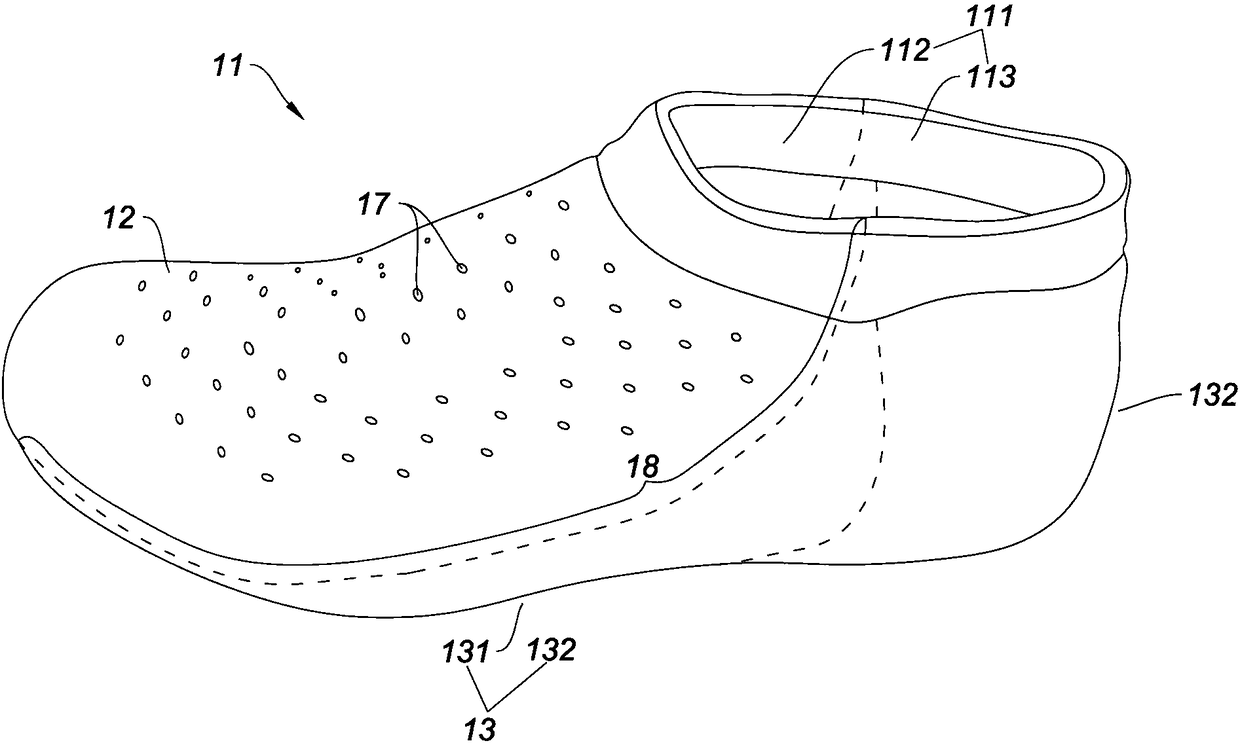

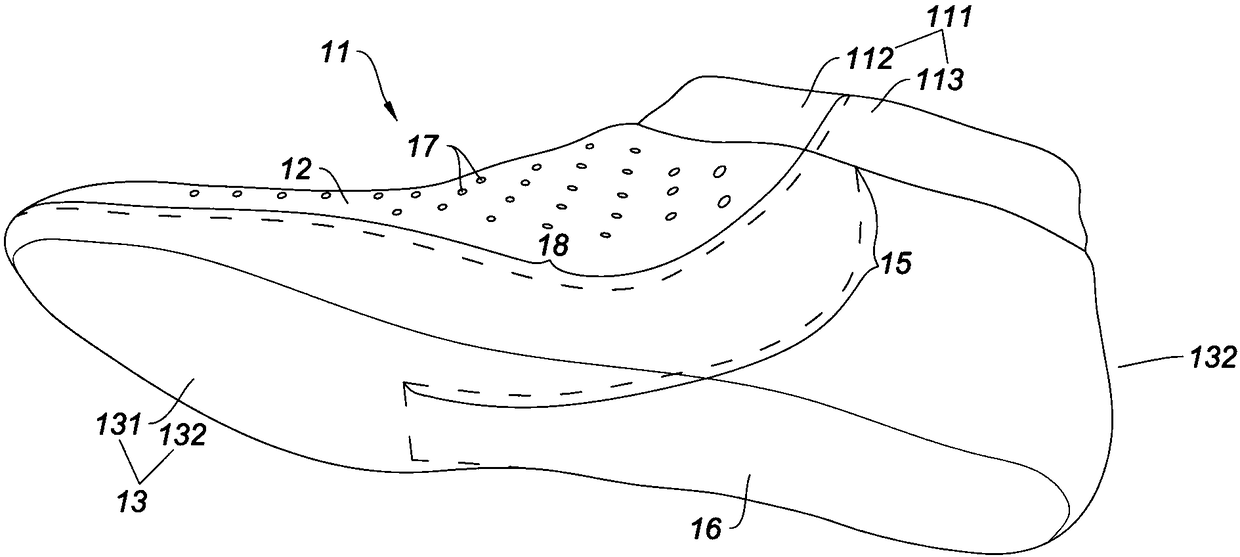

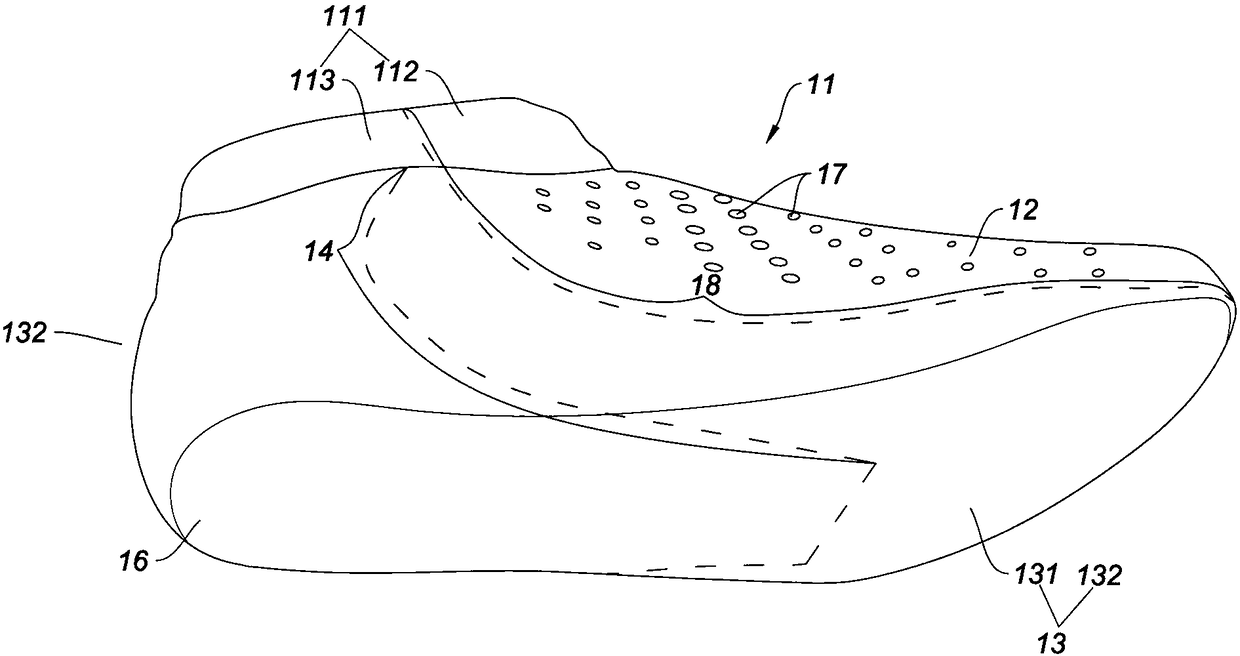

[0031] like figure 1 , figure 2 , image 3 As shown, a single-layer sock shoe in this embodiment includes a sock shoe body 11, the sock shoe body 11 is knitted by knitting thread at one time; the sock shoe body 11 is formed with a sock shoe mouth, and the sock shoe body There is a ring of double-layer elastic tensioning part 111 formed on the shoe mouth. The sock shoe body 11 includes a sock top piece 12 and a sock bottom piece 13. The sock top piece 12 and the sock bottom piece 13 are connected to form two boundary lines. 18 are respectively located on the two sides of the sock shoe body 11. The sock bottom sheet 13 includes a sock bottom surface part 131 and a sock heel part 132. Left shovel stitch marks 14 and right shovel stitch marks 15 are formed on the sock bottom sheet 13. , the left shovel stitch marks 14 and the right shovel stitch marks 15 are hook-shaped structures extending from the sock heel portion 132 to the sock bottom surface portion 131 respectively, and ...

Embodiment 2

[0036] like Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown in the present embodiment, a method for producing single-layer socks and shoes includes the following production steps:

[0037] 1) Preparation before production: check the flat knitting machine, input the knitting program for the flat knitting machine, and install the knitting thread for the flat knitting machine;

[0038] 2) Production of the elastic tension part 231 on the body 23 of the socks and shoes: start the flat knitting machine, such as Figure 4 As shown, the first row of needles 21 and the second row of needles 22 of the flat knitting machine start knitting production at the sock shoe mouth of the sock shoe body 23 at the same time, wherein: the first row of needles 21 of the flat knitting machine knits the first half circle of production In the elastic tensioning part 232 , the needles with odd numbers in the first row of needles 21 are single-sized needles, the needles with even nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com