Granary capable of dehumidifying and dissipating heat

A granary and grain storage technology, applied in the dehumidification and heat dissipation granary field, can solve the problems of uneven dehumidification and low dehumidification efficiency, and achieve the effect of accelerating the diffusion speed, improving efficiency and extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

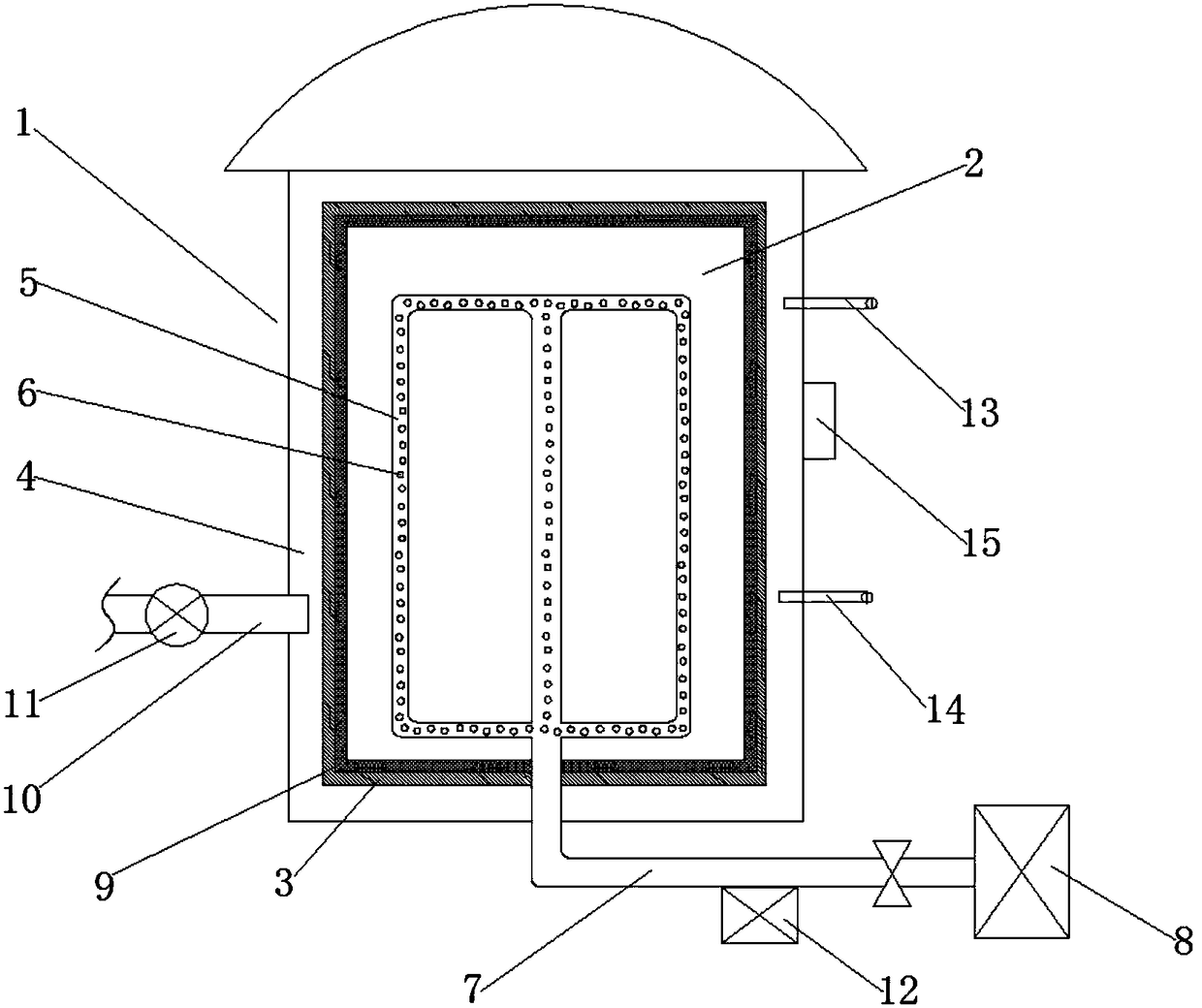

[0017] Such as figure 1 A granary that can dehumidify and dissipate heat is shown, the granary 1 is provided with a grain storage cavity 2, and the cavity wall 3 of the grain storage cavity 2 is a mesh structure, and the mesh size of the mesh structure is not larger than the particle size of the grain , a gas passage 4 is formed between the grain storage chamber 2 and the inner wall of the granary 1, and an exhaust device communicating with the outside of the granary 1 is connected to the gas passage 4, and a plurality of Parallel dehumidification pipeline 5, said dehumidification pipeline 5 evenly has a plurality of through-holes 6, and a plurality of said dehumidification pipelines 5 are all connected with the intake main pipe 7, and said intake main pipe 7 extends to the outside of the granary 1, and connects with the granary 1 external inert gas installation 8 connection.

[0018] In the above-mentioned embodiment, a dehumidification pipeline 5 is arranged inside the grai...

Embodiment 2

[0020] Based on Example 1, such as figure 1 As shown, the inner wall of the grain storage cavity 2 is also provided with a filter cloth 9, and the aperture of the filter cloth 9 is not larger than the mesh size of the mesh structure. By setting the filter cloth 9 on the inner wall of the grain storage cavity 2, dust impurities in the grain are prevented from entering the gas passage 4, causing accumulation of dust in the gas passage 4, improving the life of the equipment, and prolonging the maintenance cycle.

Embodiment 3

[0022] Based on Example 1, such as figure 1 As shown, the exhaust device includes an exhaust pipe 10 communicated with the gas channel 4 , and an induced draft fan 11 is arranged on the exhaust pipe 10 . Through the arrangement of the induced draft fan 11, the diffusion speed of the gas can be accelerated, and the efficiency of dehumidification and heat dissipation can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com