Method and device for determining fault range of r2r manufacturing system

A fault range and manufacturing system technology, applied in the field of information processing, can solve problems such as failure to adopt, monitoring abnormal faults in the manufacturing process, and high false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

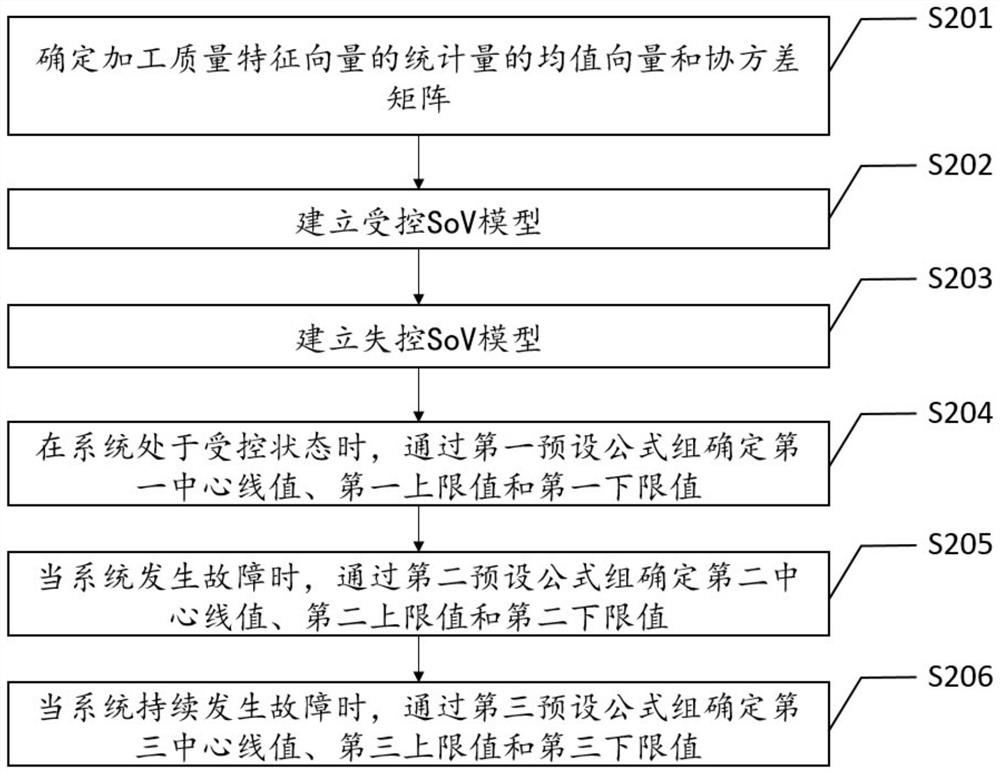

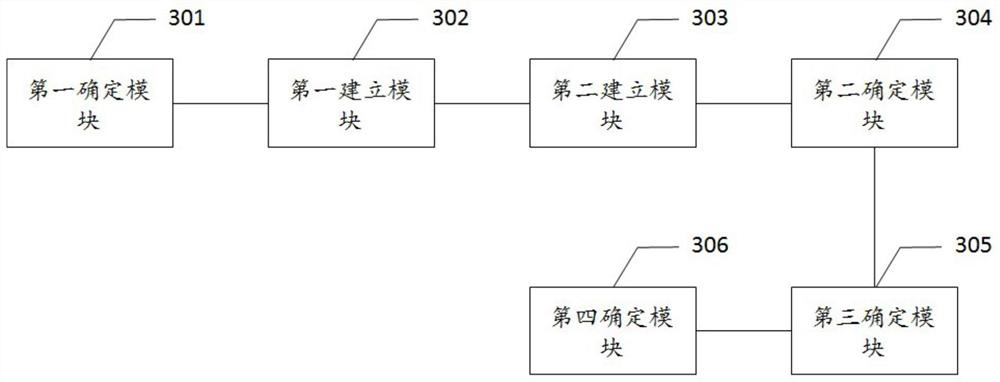

[0080] The embodiment of the present invention provides a method and device for determining the fault range of an R2R manufacturing system, which solves the problem of existing fault determination methods such as single-factor control charts, multi-factor control charts, and regression adjustment control charts when monitoring a multi-station system. The problem of high false alarm rate, especially when there is autocorrelation in the process data, cannot use the conventional control chart under the assumption of independence to monitor the technical problem of abnormal faults in the manufacturing process.

[0081] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com