Shear box applicable to vertical ring-shear test

A shearing box and ring shearing technology, applied in the field of shearing box, can solve the problems of reduced precision of shearing force, inconsistent shearing displacement, inconsistent distribution of shearing line speed, etc., achieve convenient and fast operation process, and improve operation stability , Reduce the effect of frictional heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

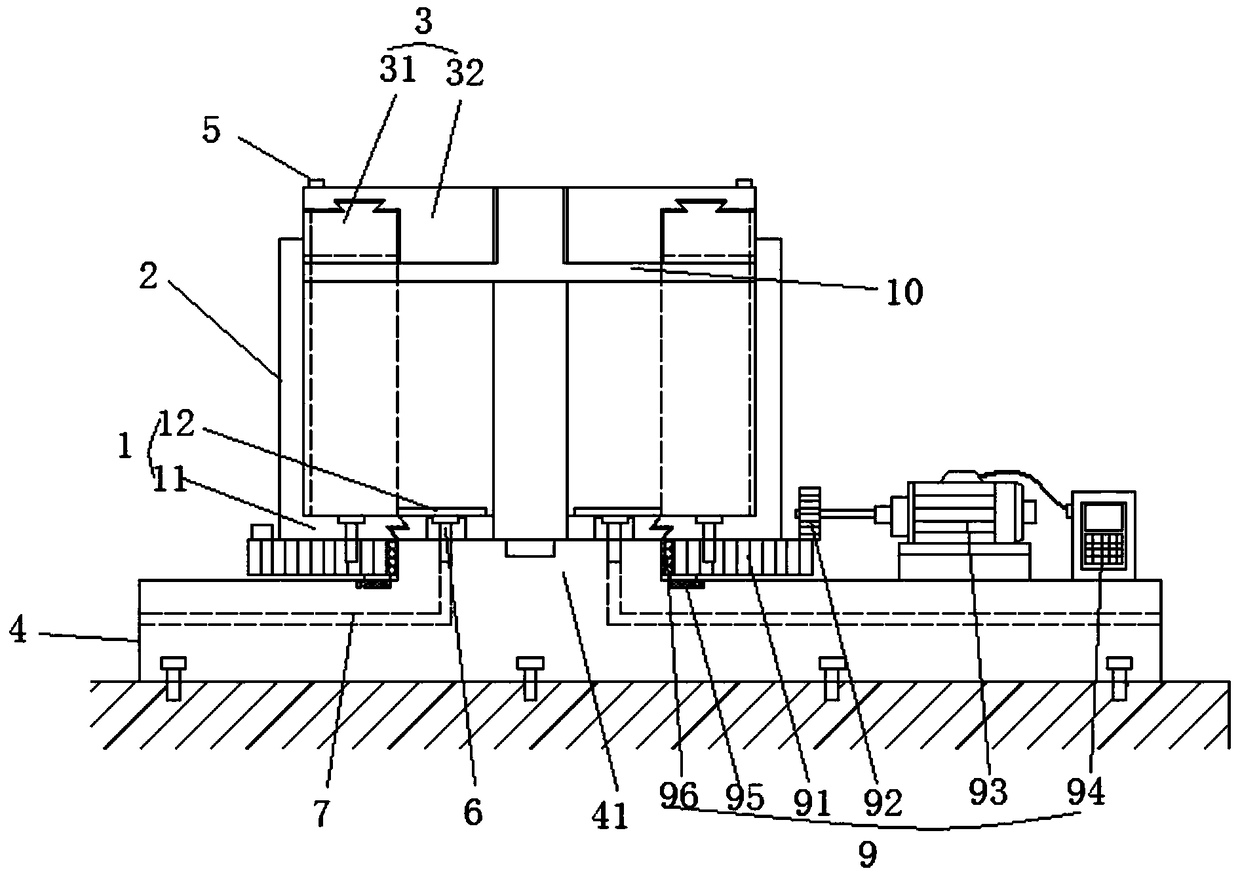

[0030] Please refer to figure 1 , the embodiment of the present invention provides a kind of shear box that is suitable for vertical ring shear test, comprises bottom plate 1, outer cover 2, top cover 3 and top cover fixing bar 10, reserves a cylindrical hole in the middle of shear box, When the instrument is not in use, the top cover fixing rod 10 is installed in the cylindrical hole. When the test is carried out, the top cover fixing rod 10 is taken out and the normal stress loading device is installed.

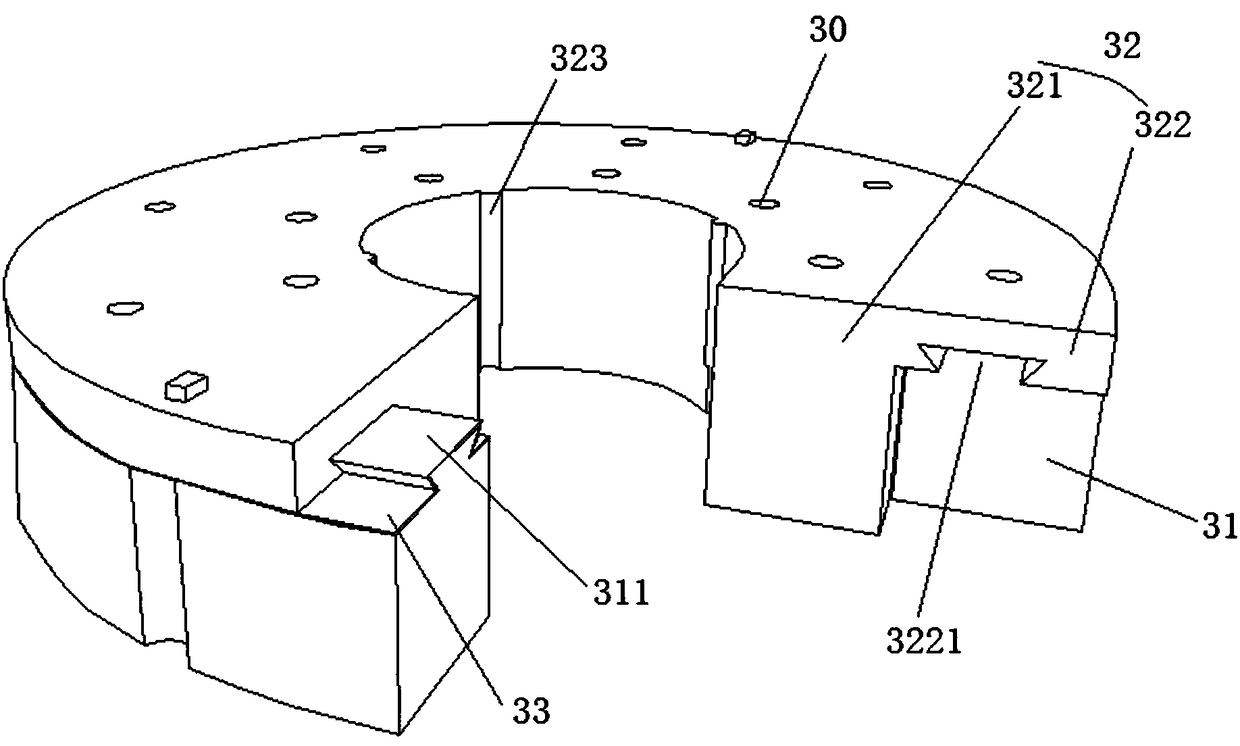

[0031] Please refer to figure 1 , 2and 4, the bottom plate 1 includes an outer bottom plate 11 and an inner bottom plate 12 that are slidably mounted together, the outer bottom plate 11 can rotate in a circular direction, and the circular rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com