Method for preparing bismuth selenide nanosheet on mica substrate by controlling gas flow

A technology for controlling gas and bismuth selenide, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of low material deposition rate and Se vacancies, and achieve high material deposition rate, large nanosheet size, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

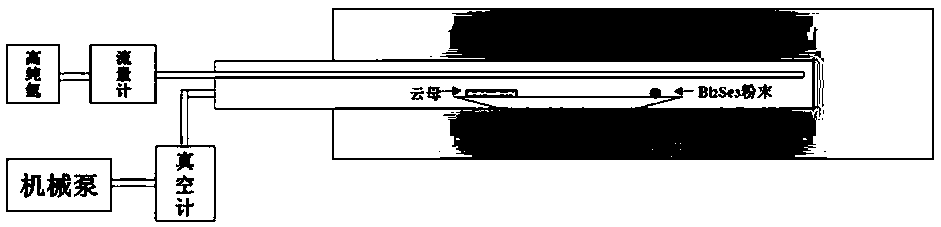

Embodiment 1

[0020] Take 0.3g high-purity Bi 2 Se 3 The powder is placed at one end of the quartz boat as the source material, and the freshly stripped mica substrate is placed at a position downstream of the carrier gas 32cm away from the source material, and then the quartz boat is placed in a single-port quartz tube with a diameter of 6cm, and high-purity argon is used as the carrier gas To transport the source material vapor, a thin quartz tube with a diameter of 5 mm is inserted into the single-port quartz tube for gas delivery. First use a mechanical pump to evacuate the chemical vapor deposition system to 15Pa, and then use high-purity argon gas to wash it for more than 3 times to exhaust the residual oxygen in the quartz tube. When the tube furnace reaches the set growth temperature of 600°C, push the quartz tube into the tube furnace so that the source material is located in the center of the tube furnace, and at the same time turn on the gas flow meter to feed 50 sccm high-purit...

Embodiment 2

[0022] Take 0.3g high-purity Bi 2 Se 3 The powder is placed at one end of the quartz boat as the source material, and the freshly stripped mica substrate is placed at a position downstream of the carrier gas 32cm away from the source material, and then the quartz boat is placed in a single-port quartz tube with a diameter of 6cm, and high-purity argon is used as the carrier gas To transport the source material vapor, a thin quartz tube with a diameter of 5 mm is inserted into the single-port quartz tube for gas delivery. First use a mechanical pump to evacuate the chemical vapor deposition system to 15Pa, and then use high-purity argon gas to wash it for more than 3 times to exhaust the residual oxygen in the quartz tube. When the tube furnace reaches the set growth temperature of 600°C, push the quartz tube into the tube furnace so that the source material is located in the center of the tube furnace, and at the same time turn on the gas flow meter to feed in 70 sccm high-pu...

Embodiment 3

[0024] Take 0.3g high-purity Bi 2 Se 3 The powder is placed at one end of the quartz boat as the source material, and the freshly stripped mica substrate is placed at a position downstream of the carrier gas 32cm away from the source material, and then the quartz boat is placed in a single-port quartz tube with a diameter of 6cm, and high-purity argon is used as the carrier gas To transport the source material vapor, a thin quartz tube with a diameter of 5 mm is inserted into the single-port quartz tube for gas delivery. First use a mechanical pump to evacuate the chemical vapor deposition system to 15Pa, and then use high-purity argon gas to wash it for more than 3 times to exhaust the residual oxygen in the quartz tube. When the tube furnace reaches the set growth temperature of 600°C, push the quartz tube into the tube furnace so that the source material is located in the center of the tube furnace, and at the same time turn on the gas flow meter to feed in 90 sccm high-pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com