Cavitation jet cleaning cavitator

A cavitation and jet technology, applied in the field of cavitation, can solve the problems of limited cavitation effect and poor cleaning effect, and achieve the effects of enhancing the cavitation cleaning effect, reducing energy consumption, and enhancing the cavitation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

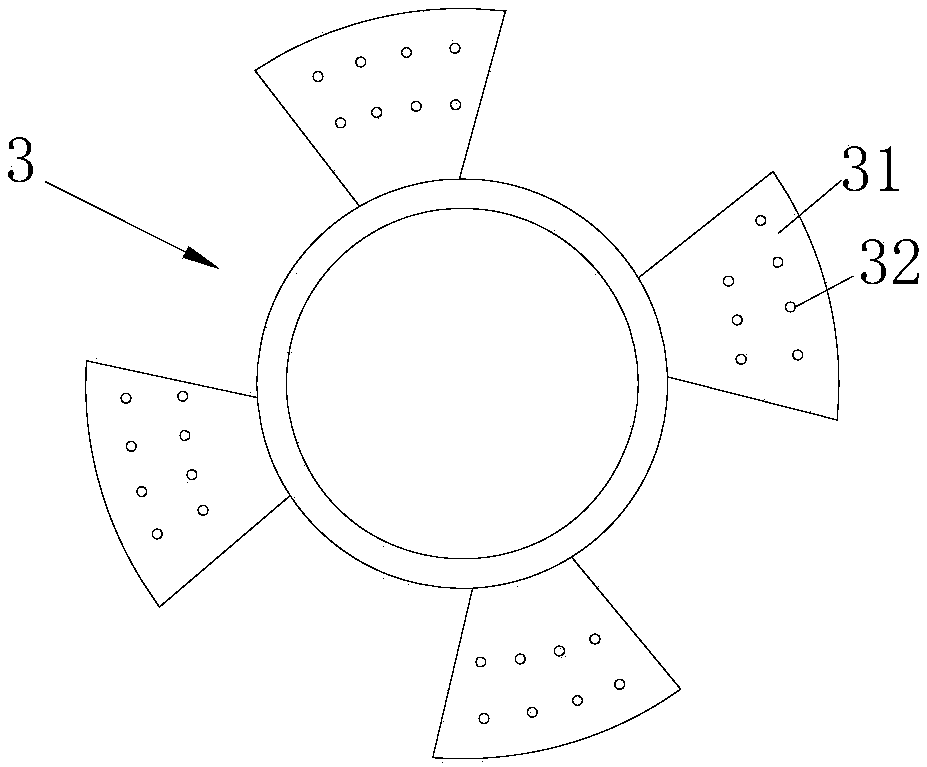

[0020] Embodiment one: if figure 1 , 2 As shown, this embodiment includes a pump and a casing 1, and a cavitation passage 2 is arranged in the casing 1, and the cavitation passage 2 includes an inlet 11 and an outlet 12, wherein the water outlet of the pump is connected to the inlet 11 of the cavitation passage 2 connected. The cavitation channel 2 includes two-stage Venturi lumens connected in series and connected in sequence. Each level of Venturi lumens includes an entrance section, a constriction section, and a throat section. Both the entrance section and the throat section are straight circular pipe structures, and The diameter of the throat section is 0.3 times the diameter of the inlet section. The two-level Venturi lumens are respectively the first-level Venturi lumen 21 and the second-level Venturi lumen 22. The first-level Venturi lumen 21 includes an entrance section 211, a constriction section 212, and a throat section 213. The second-level Venturi lumen Cavity...

Embodiment 2

[0024] Embodiment 2: The only difference from Embodiment 1 is that the through hole is a tapered hole, the opening on the tapered hole opposite to the entrance of the cavitation channel is a large opening, and the opening on the tapered hole opposite to the outlet of the cavitation channel is a small opening .

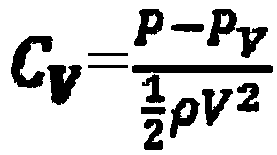

[0025] The cavitation number is a dimensionless parameter describing the cavitation state. The calculation formula of the cavitation number is as follows:

[0026]

[0027] The cavitation number at the midpoint of the Venturi tube axis can be calculated by this formula, in the formula: C V is the cavitation number, P is the incoming pressure of the liquid, P V is the saturated vapor pressure of the liquid at ambient temperature, ρ is the density of the liquid, and V is the flow rate of the liquid.

[0028] Among them, the smaller the cavitation number, the stronger the cavitation effect. Through the measurement and calculation of experimental data, the cavitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com