Plant electric load distribution method

A technology for load distribution and plant power consumption, applied in the field of electric power, which can solve problems such as inability to maintain load balance and breakage of load balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

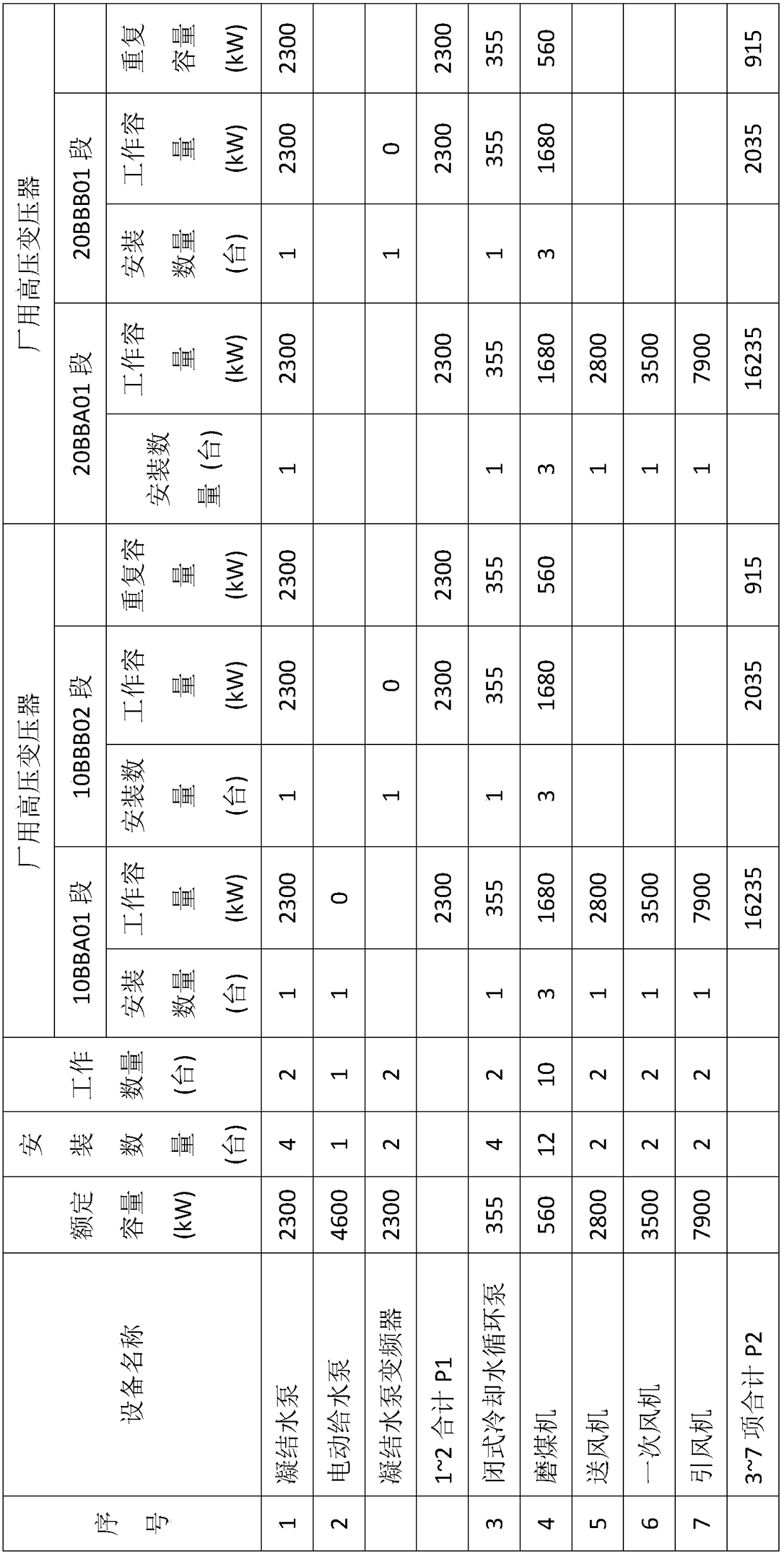

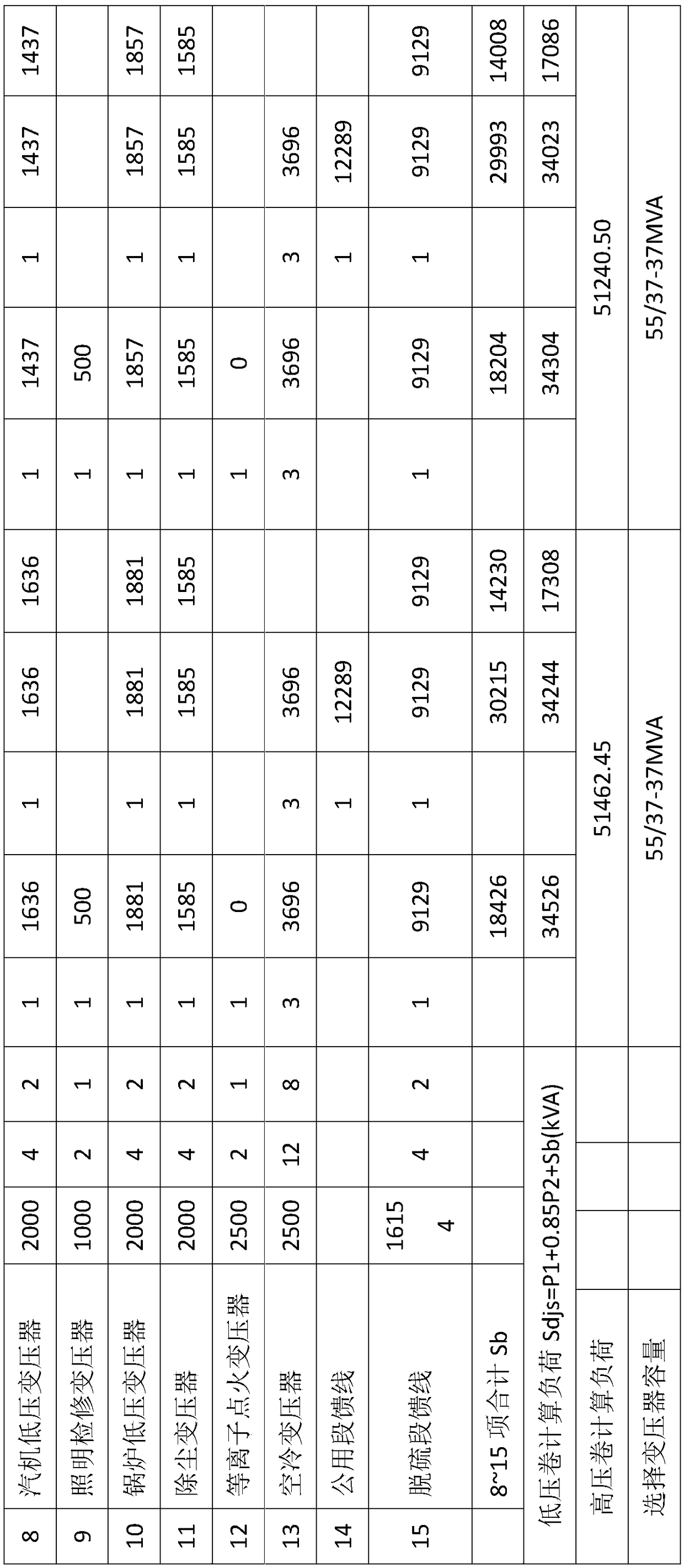

[0027] First, see figure 1 , the invention provides a method for distributing utility power loads, comprising:

[0028] The medium-voltage plant power system includes two units, namely the first unit 1 and the second unit 2, and two sections of medium-voltage working busbars are set up for each unit, of which the first unit 1 is equipped with two sections of medium-voltage working busbars 10A, 10B, the second unit 2 is equipped with two sections of medium-voltage working busbars 20A and 20B, and two sections of medium-voltage common busbars 01A and 01B are set up for the first unit 1 and the second unit 2, of which 01A is drawn from the first unit 1 medium-voltage working bus The busbars 10B and 01B are led from the medium-voltage working busbar 20B of the second unit 2, and the common busbar 01A and the common busbar 01B are provided with a tie switch and a busbar 10.

[0029] Connect the two sections of medium-voltage public buses to the plant working buses tapped to differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com