A method for detecting thermal stability of polymer bonded explosives

A technology for bonding explosives and thermal stability, which is applied in the preparation of test samples, measuring devices, instruments, etc., and can solve problems such as inapplicability of detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Detection of thermal stability of sample PBX1 microstructure

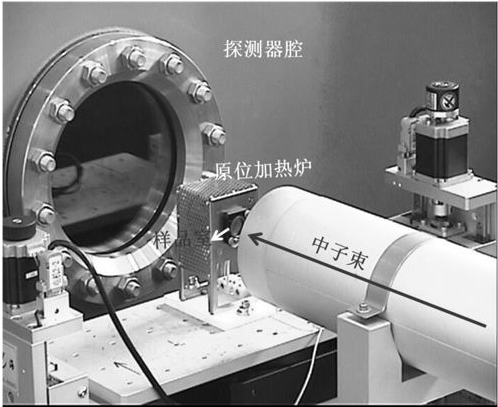

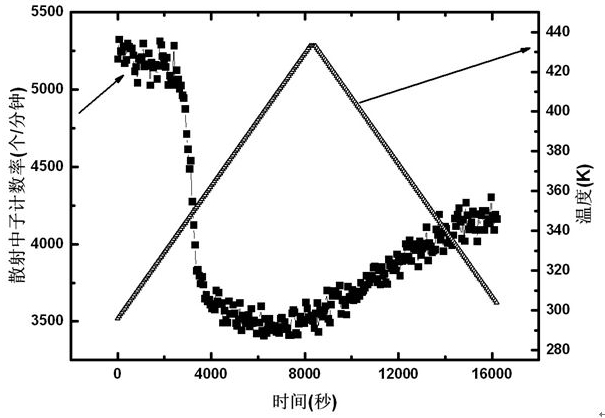

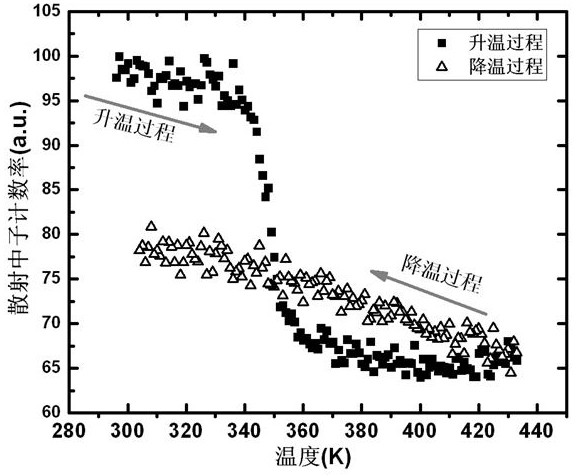

[0032] Select the molded PBX1 explosive to prepare a sheet-like PBX sample with a thickness of 1mm and a diameter of ф=10mm; figure 1 shown; then under the layout condition that the sample and the detector are 5.2 meters apart (the corresponding scattering vector q range is 0.08nm -1 ~0.8nm -1 ), carry out in situ variable temperature neutron small angle scattering experiments, raise the temperature from 303K to 433K at a heating rate of 1K / min, keep at 433K for 5min, and then cool down to 303K at a cooling rate of 1K / min, collect and record the temperature and detection of the sample The change of all scattered neutron counts on the detector with time; the change of all scattered neutron counts with time is converted into the change curve of scattered neutron count rate with time according to the time interval of 60s, such as figure 2 As shown; the change curve of the scattered neutron count ra...

Embodiment 2

[0033] Example 2 Detection of sample PBX2 microstructure thermal stability

[0034] Select the molded PBX2 explosives to prepare a sheet-like PBX sample with a thickness of 3mm and a diameter of ф=10mm; then place the sheet-like PBX sample at the neutron small scattering spectrometer sample with an in-situ temperature-changing device at the Mianyang Research Reactor; 0.08nm -1 ~0.8nm-1 Carry out in-situ variable temperature neutron small angle scattering experiments within the range of the scattering vector q, heat up from 293K to 393K at a heating rate of 1K / min, keep at 393K for 5min, and then cool down to 293K at a cooling rate of 1K / min, collect and record samples Changes with time of all scattered neutron counts on the temperature and detector; said all scattered neutron counts are converted into scattered neutron count rate change curves with time according to the time interval of 60s, such as Image 6 As shown; the change curve of the scattered neutron or X photon coun...

Embodiment 3

[0035] Example 3 Detection of thermal stability of sample PBX3 microstructure

[0036] Select shaped PBX3 explosives to prepare a sheet-like PBX sample with a thickness of 1mm and a diameter of ф=10mm; then place the sheet-like PBX sample at the neutron small scattering spectrometer sample with an in-situ temperature-changing device at the Mianyang Research Reactor; then at 0.08 nm -1 ~0.8nm -1 Carry out in situ variable temperature neutron small angle scattering experiments within the range of the scattering vector q, heat up from 293K to 393K at a heating rate of 1K / min, keep at 393K for 5min, then cool down to 293K at a heating rate of 1K / min, collect and record samples Changes with time of all scattered neutron counts on the temperature at the detector and on the detector; said all scattered neutron counts are converted into scattered neutron or X photon count rate change curves with time according to the time interval of 60s, such as Figure 8 As shown; the change curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com