A wear-resistant and pressure-stabilized plunger mud pump

A mud pump and plunger technology, which is applied in the field of wear-resistant and pressure-stabilized plunger mud pumps, can solve the problems of inconvenient replacement, difficult plunger processing, and high cost, and achieve the goals of prolonging life, reducing difficulty in heat treatment, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

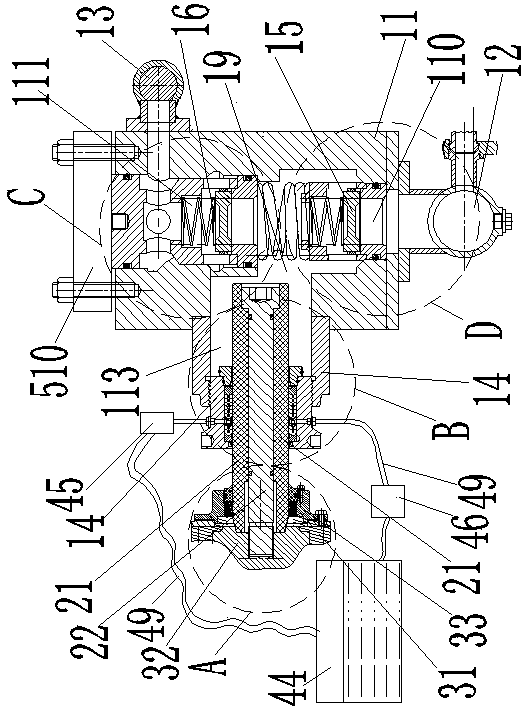

[0037] Example 1. Such as Figure 1 to Figure 10 As shown, a wear-resistant and pressure-stabilized plunger mud pump includes a transmission assembly, a plunger assembly, a sealing lubrication assembly and a valve box assembly. The port 12 and the liquid outlet 13, the inner chamber 19 arranged in the box, the right mounting hole 113 of the plunger arranged on the left side wall of the box body 11, the right mounting hole 113 of the plunger is set with a center axis transversely arranged The plunger right mounting sleeve 14, the right end of the plunger assembly is located in the inner cavity 19 of the tank, the tank 11 is provided with a liquid inlet valve 15, a liquid outlet valve 16, the liquid inlet valve 15 is connected with the liquid inlet 12, and the liquid outlet valve 16 It is connected with the liquid outlet 13.

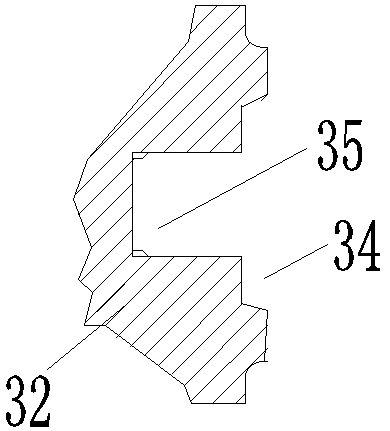

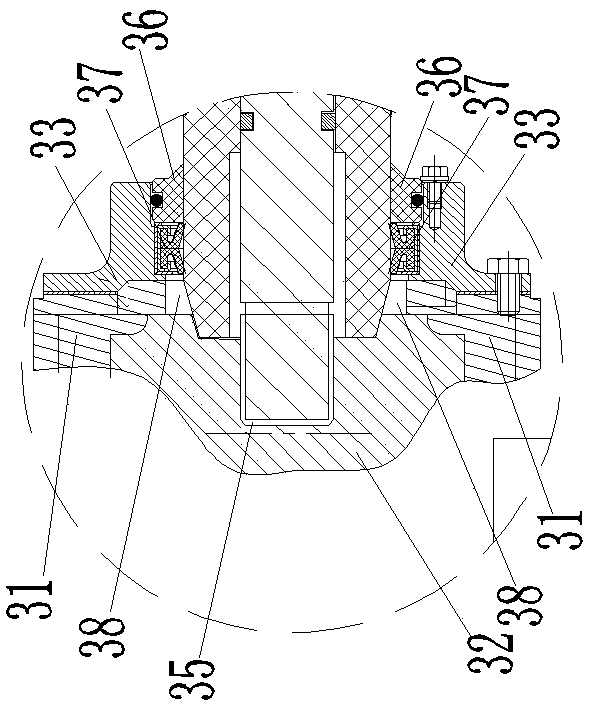

[0038] The plunger assembly includes a plunger wear-resistant jacket 21 arranged transversely to the central axis, a plunger inner shaft 22 arranged lat...

Embodiment 2

[0053] Example 2. Such as Figure 11-13 As shown, the difference between this embodiment and Embodiment 1 is that a sediment filter 410 is provided on the pipeline 49 between the oil outlet 48 and the oil-water separator 46 .

[0054] The mud pump includes a pressure relief assembly. The pressure relief assembly includes a pressure relief hole 61 on the side wall of the box body 11 that can communicate with the inside and outside of the box body 11 . The pressure relief hole 61 is provided with a valve 62 . There are multiple pressure relief devices, which can quickly release pressure and facilitate the internal maintenance of valve box components. Through the pressure relief hole, the residual mud inside the valve box assembly can also be released, which is convenient for cleaning the inside of the valve box, and the medium can also be cleaned when the mud pump is not in use, so as to avoid oxidation and freezing in winter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com