Preparation method of provenance spore microbial agent used in Aspergillus niger koji making process

A spore inoculum and a technology for producing Aspergillus niger, which is applied in the field of preparation of provenance spore inoculum in the process of koji making by Aspergillus niger, can solve the problems of quality fluctuation of bran koji, large production volume of eggplant bottles, complicated inoculation operation and the like, and achieve inoculation The link is simplified, the chance of contamination is reduced, and the effect of less chance of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

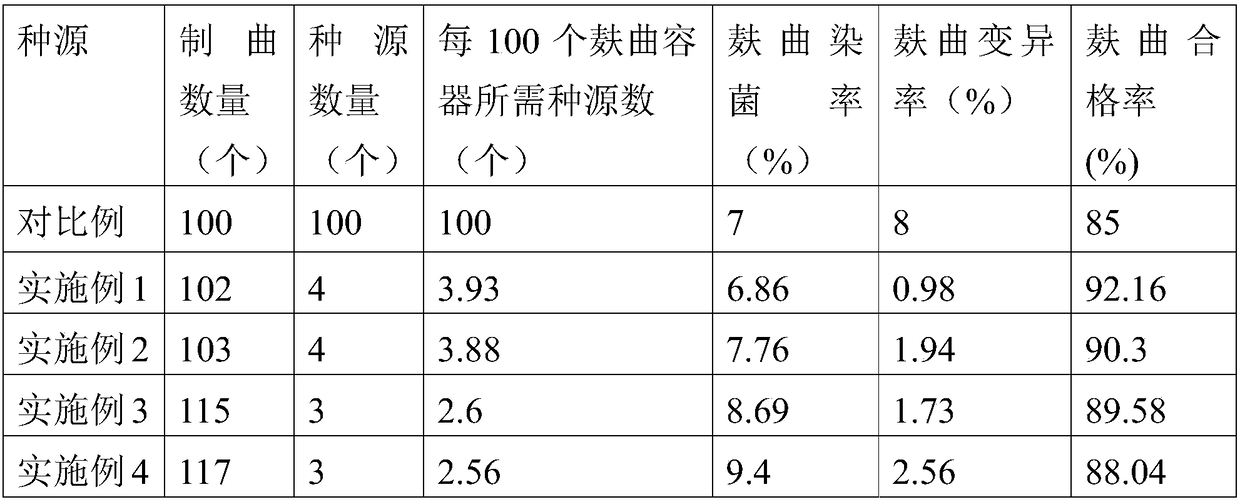

Examples

Embodiment 1

[0032] A preparation method of provenance spore bacterial agent in the Aspergillus niger koji-making process, described method comprises the steps:

[0033] (1) Cultivate provenance spores in corncob culture medium;

[0034] The selection of corn cob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: take 800g of corn steep liquor powder and glucose, 120g of ammonium sulfate, mix and dissolve with water, and make up to 6L after dissolution. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0035] Take four 2000ml triangular flasks, fill each bottle with 40g of corncob medium, add 60ml of water, sterilize at 121°C for 30min, cool to 35°C after sterilization, pick a ring of spores with an i...

Embodiment 2

[0043] A preparation method of provenance spore bacterial agent in the Aspergillus niger koji-making process, described method comprises the steps:

[0044] (1) Cultivate provenance spores in corncob culture medium;

[0045] The selection of corn cob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: Take 200g of corn steep liquor powder and glucose, 60g of ammonium sulfate, 3.4L of soybean meal hydrolyzate, mix and dissolve with water, and make up to 6L after dissolving. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0046]Take four 1000ml triangular flasks, fill each bottle with 40g of corn cob medium, add 50ml of water, sterilize at 121°C for 30min, cool to 35°C after sterilization,...

Embodiment 3

[0054] A preparation method of provenance spore bacterial agent in the Aspergillus niger koji-making process, described method comprises the steps:

[0055] (1) Cultivate provenance spores in corncob culture medium;

[0056] The selection of corn cob carrier and the preparation of soybean meal hydrolyzate are as mentioned above, and the preparation of nutrient solution is as follows: take 400g of corn steep liquor powder and glucose, 120g of ammonium sulfate, 1L of soybean meal hydrolyzate, mix and dissolve with water, and make up to 6L after dissolving. Mix 6L of nutrient solution evenly into 8kg of corncobs, and after the corncobs have completely absorbed the nutrient solution, dry them in a low-temperature drying oven at a temperature not exceeding 60°C. After drying, it is the finished culture medium.

[0057] Take three 2000ml triangular flasks, fill each bottle with 60g of corn cob medium, add 84ml of water, sterilize at 121°C for 30min, cool to 35°C after sterilization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com