Heating level-regulable coke oven structure and heating level regulation method

A coke oven and horizontal technology, applied in the field of coke ovens, can solve the problems of difficult adjustment, loss, and inability to make precise adjustments, and achieve the effect of changing the heating level and adjusting the process simply and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

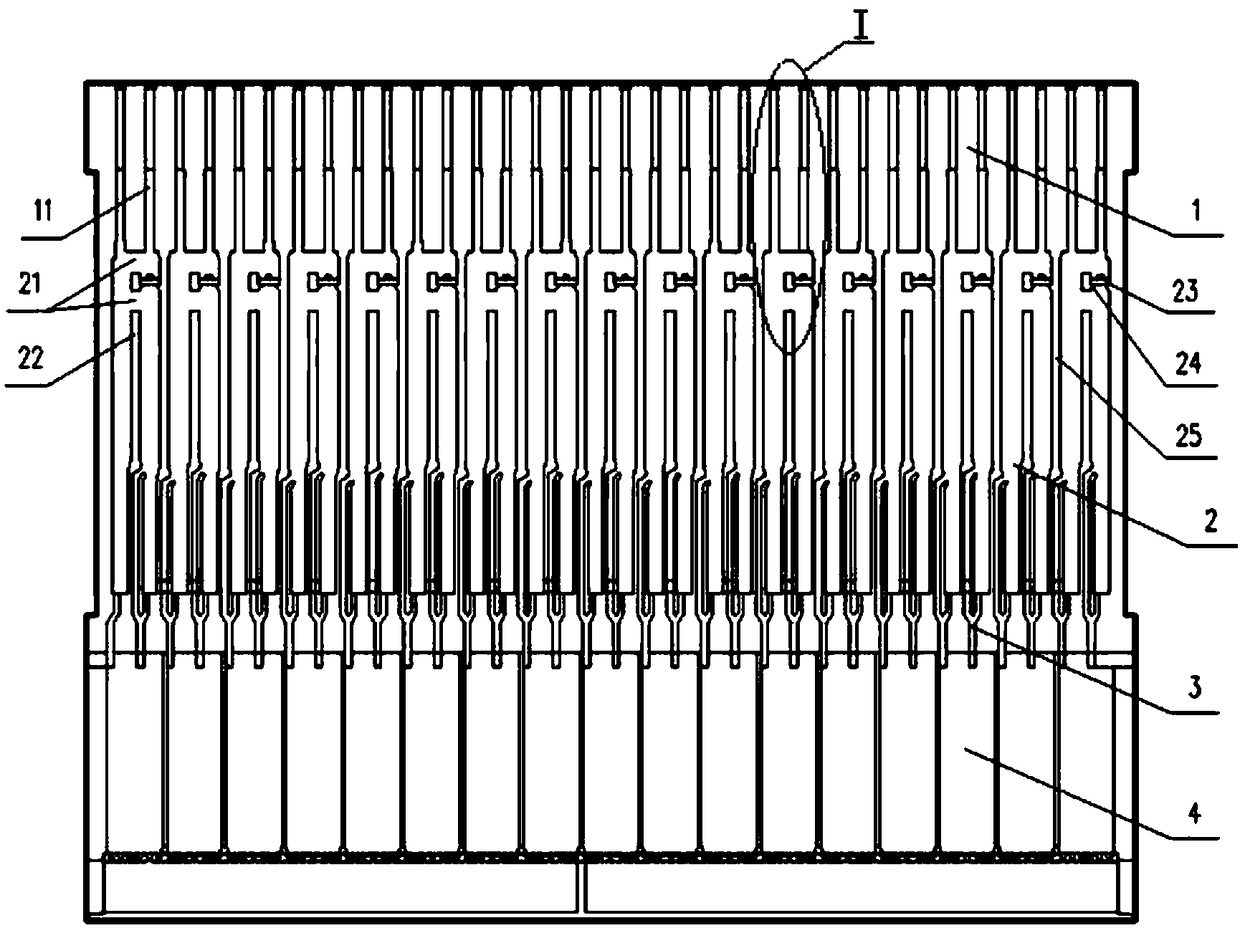

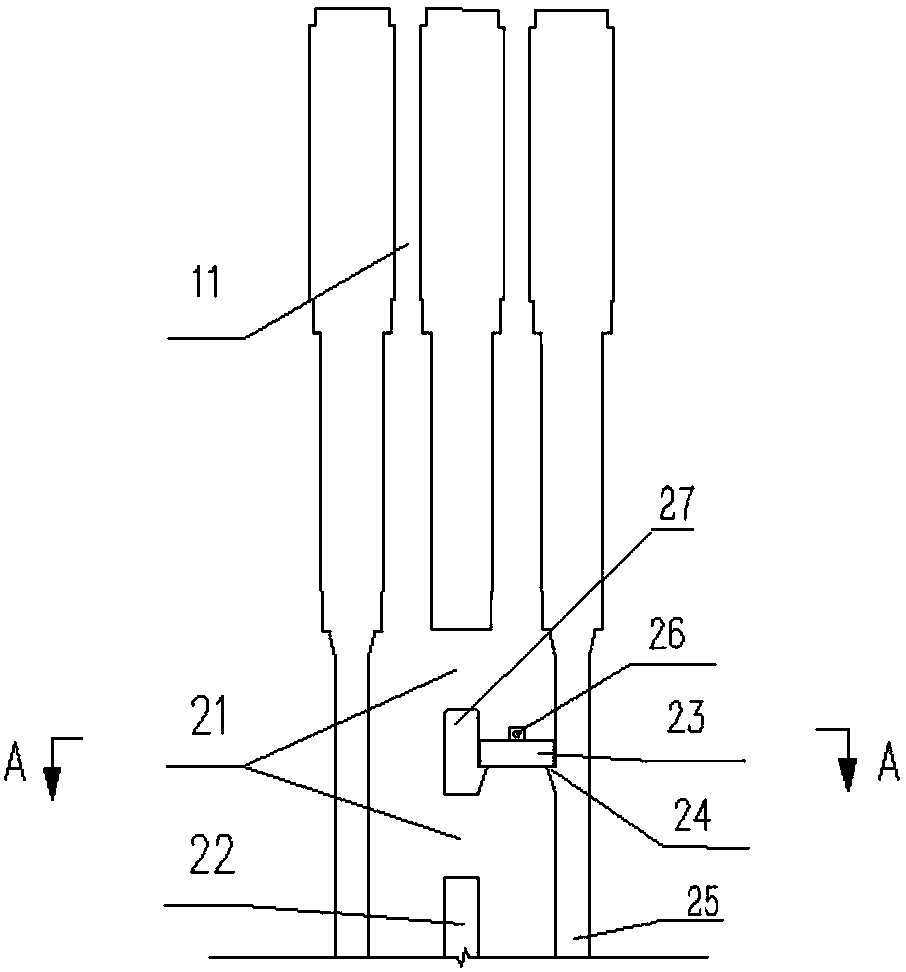

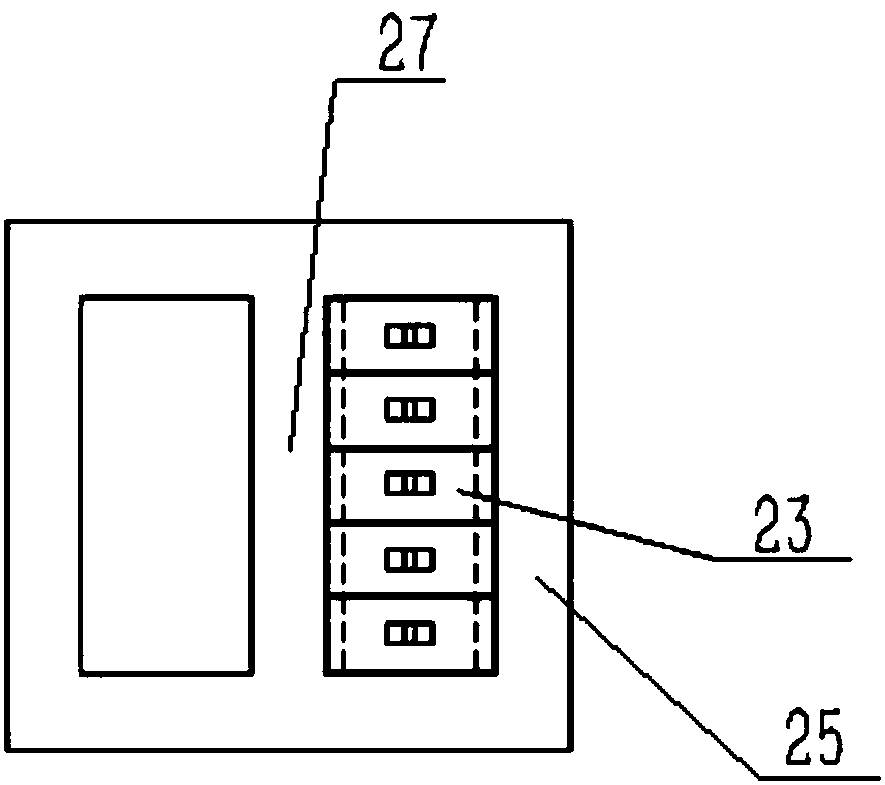

[0025] Such as Figure 1-Figure 3 As shown, the coke oven structure with adjustable heating level in the present invention includes a regenerator 4, a chute 3, a combustion chamber 2 and a furnace roof 1 arranged in sequence from bottom to top, wherein the combustion chamber 2 It consists of a number of fire passages, each fire passage top is equipped with a fire viewing hole 11, and two adjacent fire passages are separated by a fire passage partition wall 25. The fire passages are double-connected fire passages, and the double-connected fire passages The passages are separated by a double fire passage partition wall 22, and the top of the vertical fire passage is provided with a crossing hole 21 to connect the double fire passages. The crossing hole 21 is composed of an upper floor crossing hole and a lower floor crossing hole. A partition 27 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com