Reinforcing steel bar carrying robot structure

A technology for handling robots and steel bars, applied in the field of handling robots, can solve the problems of large size and structure of gantry hangers, potential safety hazards, and difficulty in turning steel bars, so as to facilitate the transportation of steel bars, avoid personnel injuries, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

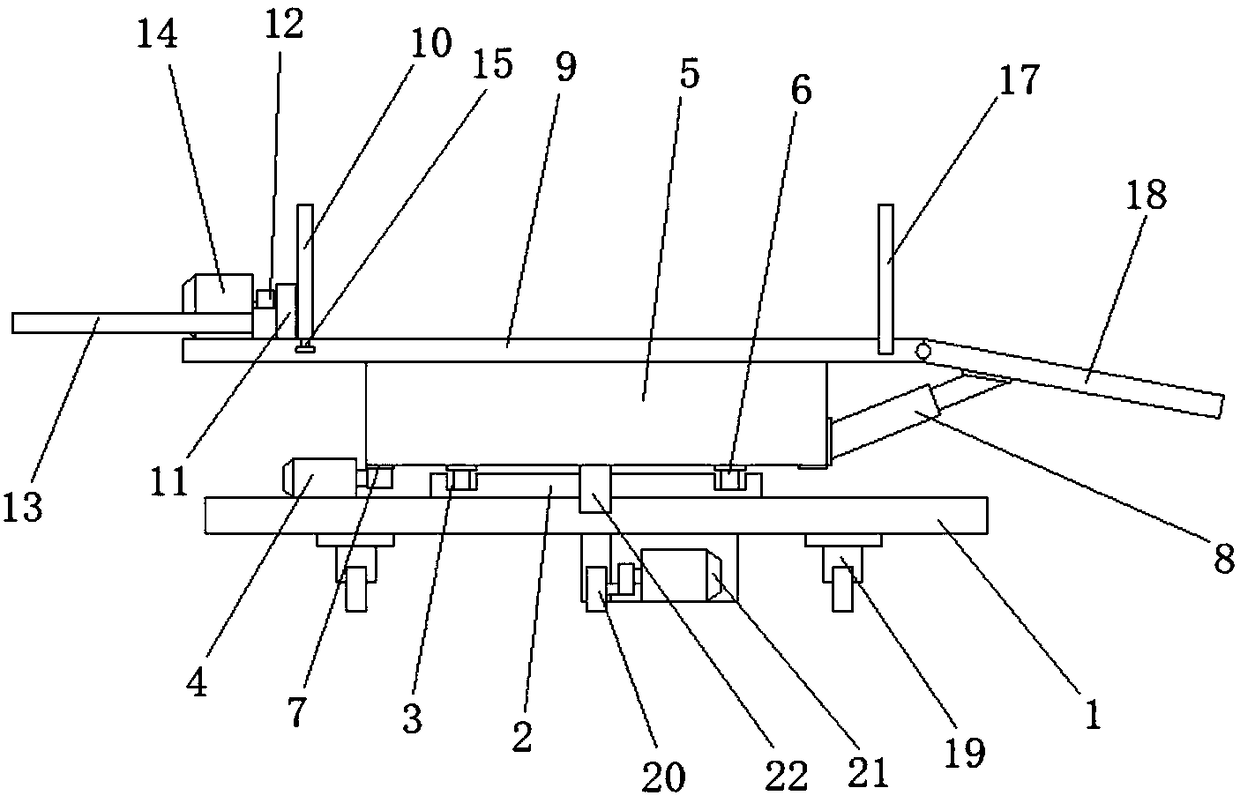

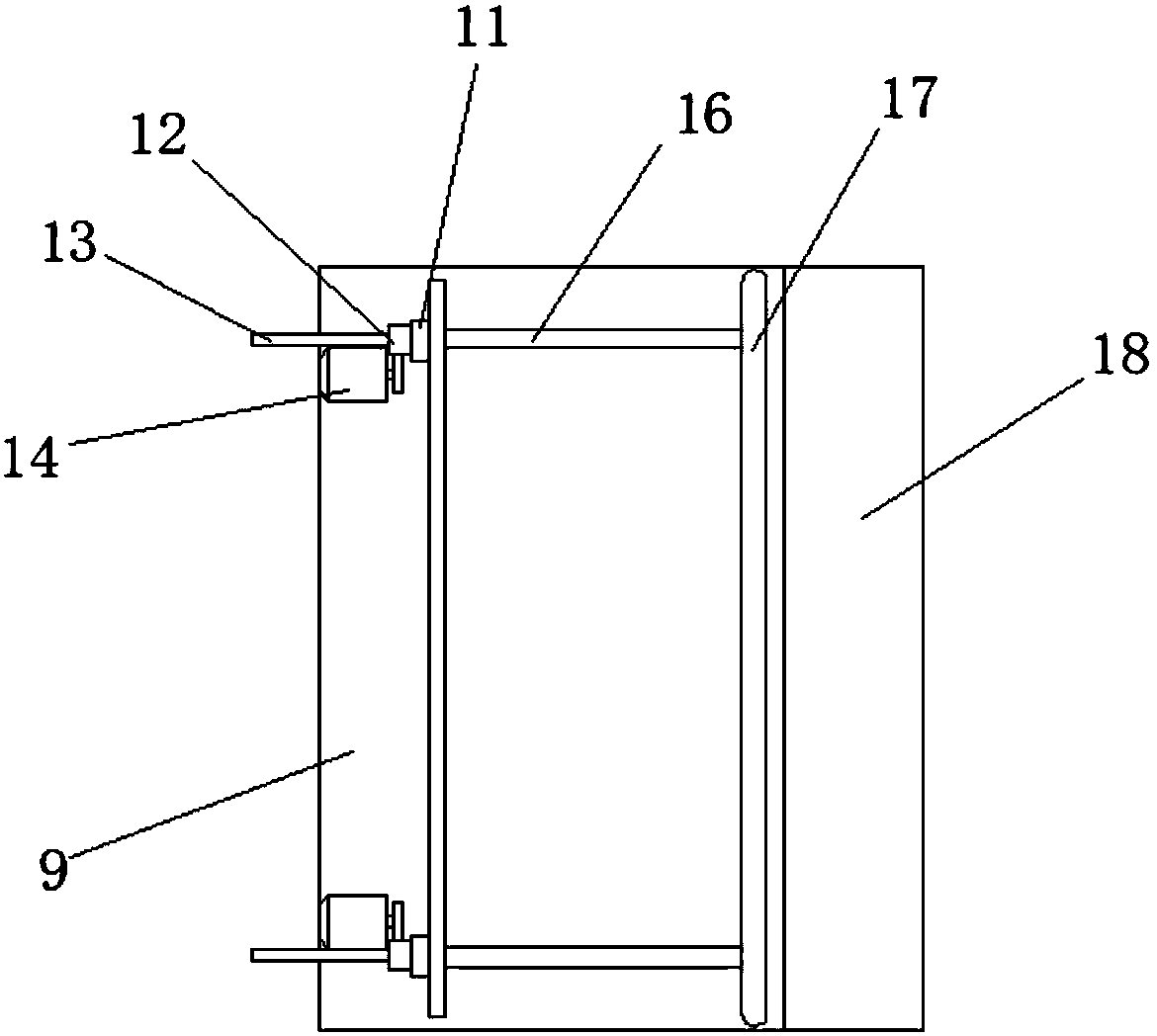

[0017] Such as Figure 1-Figure 2 As shown, a steel bar handling robot structure includes a base 1, a rotating disk 2 is provided on the top of the base 1, a rotating groove 3 is provided on the top of the rotating disk 2, and a rotating motor is provided on one side of the rotating disk 2. 4. There is a supporting seat 5 above the rotating disk 2, and a rotating wheel 6 is provided at the bottom of the supporting seat 5, which can make the placing plate 9 rotate, and change the direction of the sliding plate 18 according to the placing position, thereby changing the direction of unloading steel bars , and the rotating wheel 6 is located in the inner cavity of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com