Robot-based electronic element hand-eye coordination plug-in mechanism

An electronic component, hand-eye coordination technology, applied in electrical components, electrical components, manipulators, etc., can solve the problems of low plug-in efficiency, difficult positioning, and inability to adjust the angle of industrial cameras, so as to improve adaptability, improve plug-in accuracy, save money The effect of human resources and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

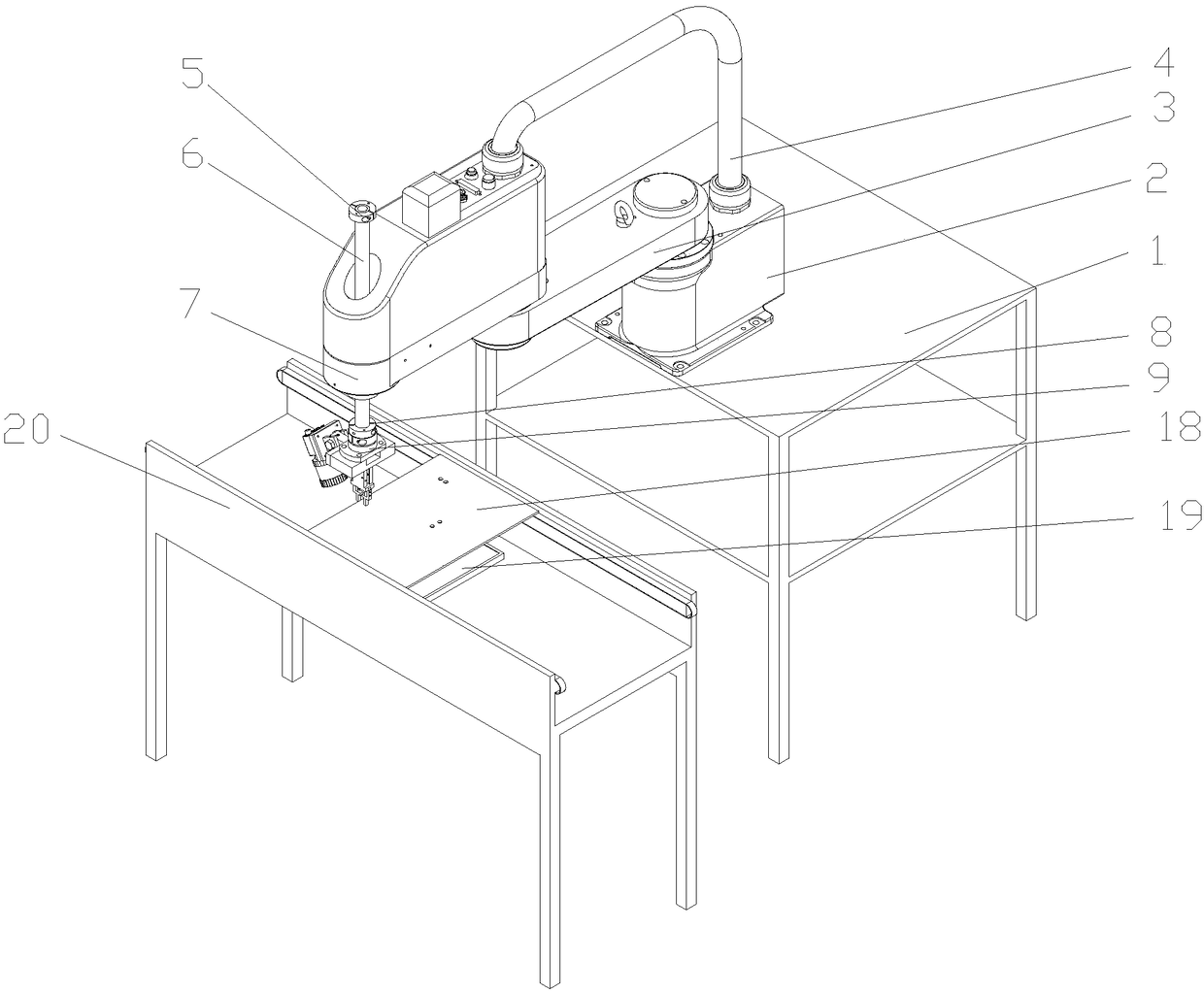

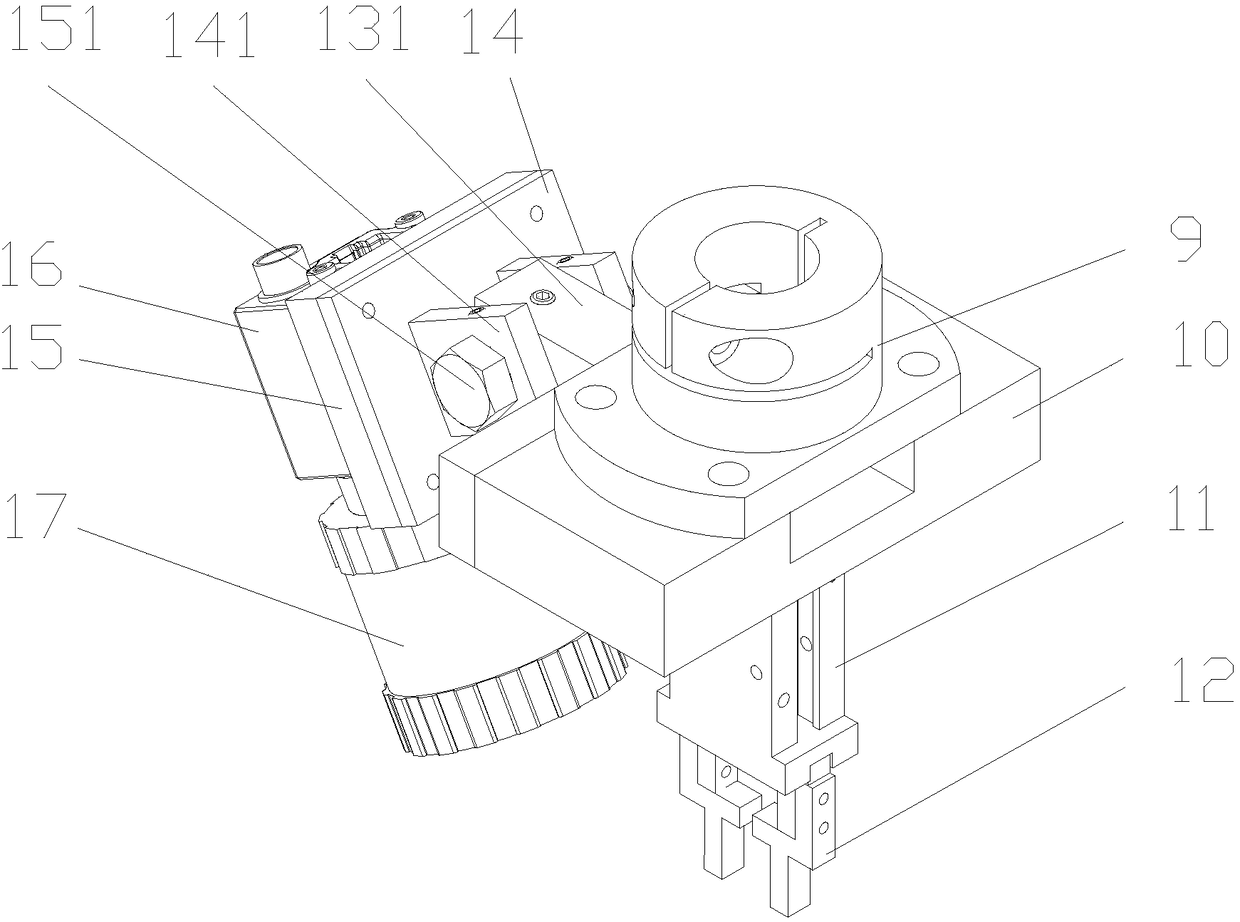

[0031] Such as figure 1 with figure 2 shown. The invention discloses a hand-eye coordination plug-in mechanism for electronic components based on a robot, which includes an industrial four-degree-of-freedom robot arranged on a workbench 1; the industrial four-degree-of-freedom robot includes a screw rod 6 installed on a forearm 7; the screw rod The lower end of 6 is equipped with a parallel opening and closing type pneumatic gripper mechanism; the side of the parallel opening and closing type pneumatic gripper mechanism is connected with a movable transfer mechanism for installing the industrial camera 16;

[0032] The movable transfer mechanism includes a first transfer board 13 and a second transfer board 14; the first transfer board 13 has a shoulder 131, and the second transfer board 14 has a concave corresponding to the shoulder 131. shoulder 141, the protruding shoulder 131 is placed in the concave shoulder 141, and the protruding shoulder 131 and the concave shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com