Electric actuator press-fitting operating table

A technology of electric actuator and operating table, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of non-vertical pressing angle, insufficient pressing force, and unequal terminal inclination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

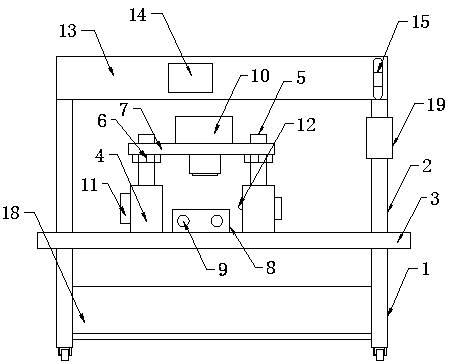

[0022] like Figure 1-2 As shown, an electric actuator press-fitting operation table of the present invention includes a lower bracket 1 and an upper bracket 2, the lower bracket 1 and the upper bracket 2 are fixedly connected by a support plate 3, and four support columns 4 are arranged on the top of the support plate 3 A HYYL electronic pressure gauge 11 is installed on one side of one of the support columns 4, which can detect the downforce of the motor when it is pressed, and a camera 12 is installed on one side of the other support column 4, which is convenient for observing the installation of the motor. The inclination angle of the terminal can be adjusted accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com