System and method for preventing excessive flying shear tail

A flying shear, oversized technology, applied in the field of steel rolling, can solve the problem of oversized cutting tail, and achieve the effect of avoiding flying shears from being stuck, preventing flying shearing tails from being oversized, reducing push waste and abnormal shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

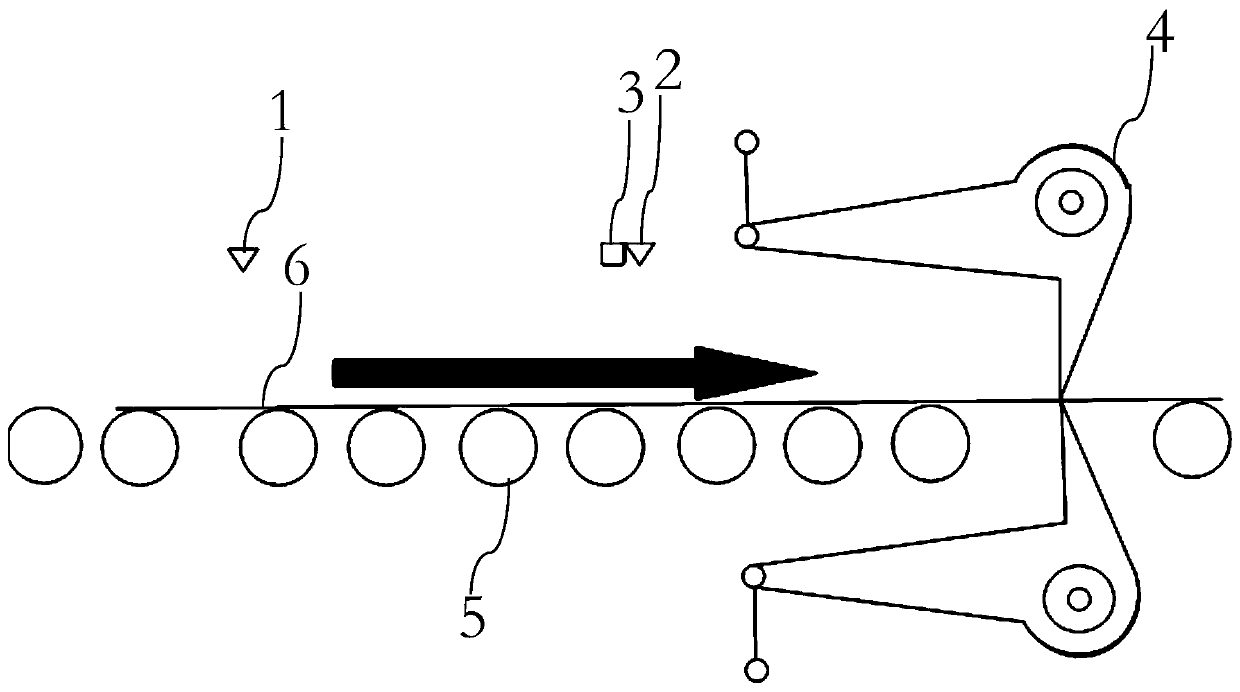

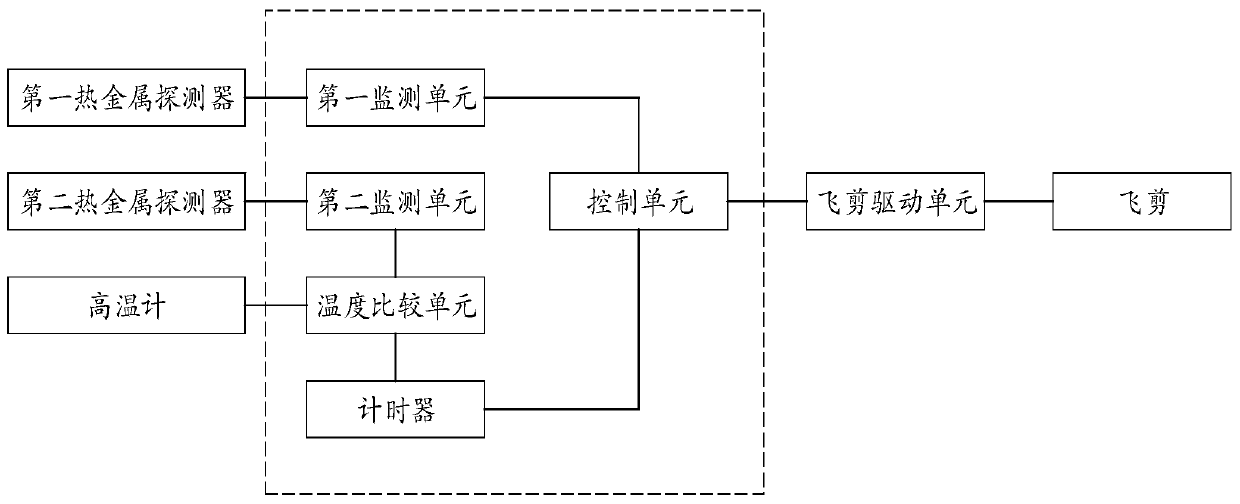

[0036] see figure 1 , the present embodiment provides a system for preventing the flying shear tail from being too large, and the system includes: a roller table 5, a first hot metal detector 1, a second hot metal detector 2, a pyrometer 3, and a flying shear driving unit , flying shear 4 and controller. The first hot metal detector 1, the second hot metal detector 2 and the pyrometer 3 are arranged above the roller table 5; the second hot metal detector 2 and the pyrometer 3 are arranged on the downstream of the first hot metal detector 1, This downstream refers to the downstream of strip steel 6 running direction, figure 1 The direction indicated by the middle arrow is the running direction of strip 6. The irradiation points of the second hot metal detector 2 and the pyrometer 3 on the steel strip 6 are set at the same position, and the measuring range of the pyrometer 3 is 600-1200°C. The flying shear driving unit is connected with the flying shear 4, and drives the flyi...

Embodiment 2

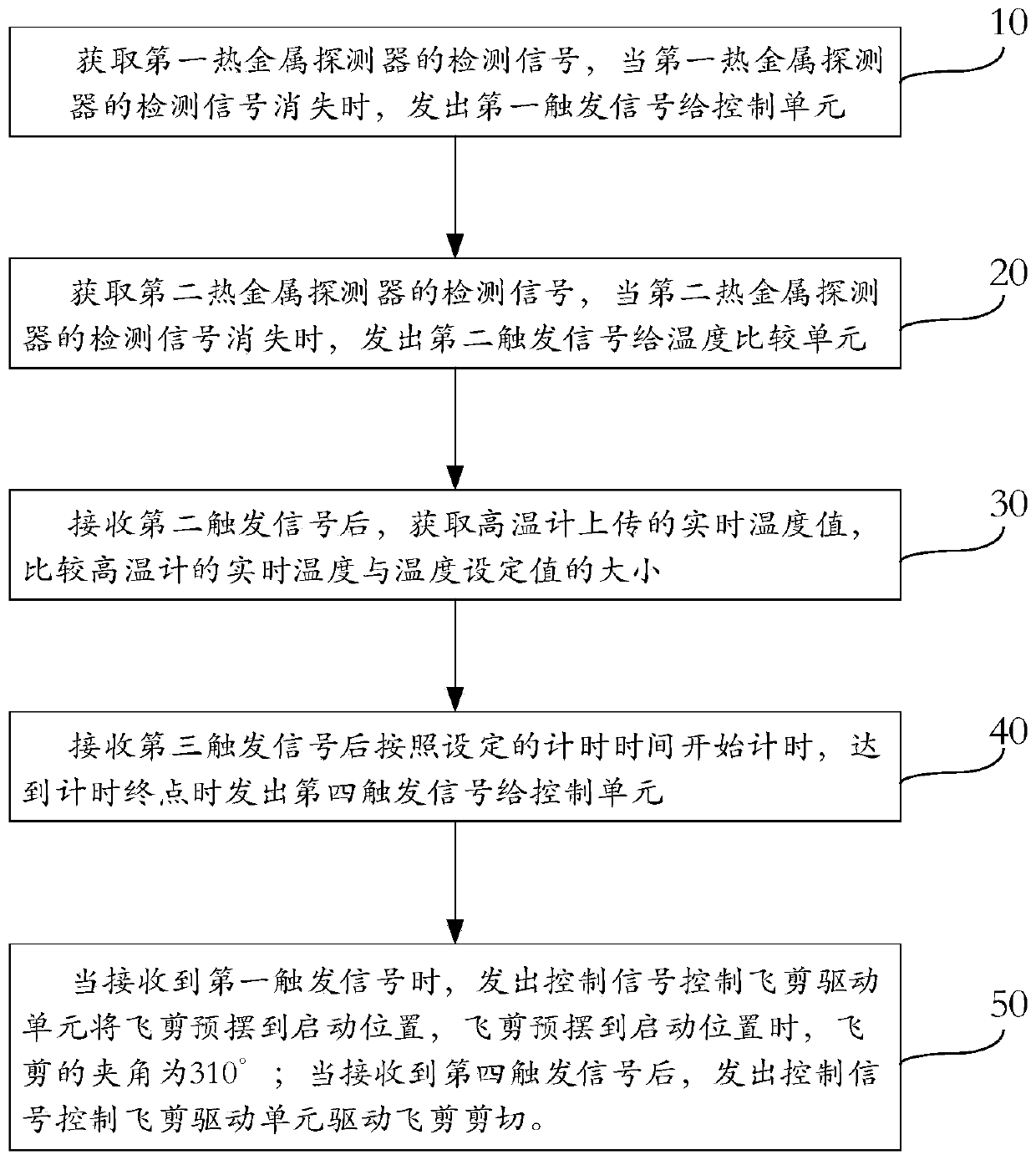

[0044] see figure 1 and image 3 , present embodiment provides a kind of method that prevents flying shear tail from being too large, and this method is that strip steel 6 realizes after running on roller table 5, comprises the following steps:

[0045] Step 10, acquiring the detection signal of the first hot metal detector 1, and sending a first trigger signal to the control unit when the detection signal of the first hot metal detector 1 disappears.

[0046] Step 20, acquiring the detection signal of the second hot metal detector 2, and sending a second trigger signal to the temperature comparison unit when the detection signal of the second hot metal detector 2 disappears.

[0047] Step 30, after receiving the second trigger signal, obtain the real-time temperature value uploaded by the pyrometer 3, and compare the real-time temperature of the pyrometer 3 with the temperature setting value. In this embodiment, the temperature setting value is 700°C. If the real-time temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com