Stapler with cutting mechanism

A cutting mechanism and stapler technology, applied in the field of medical devices, can solve problems such as easy collapse, insufficient anvil strength, and inability to completely cut tissues and staples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

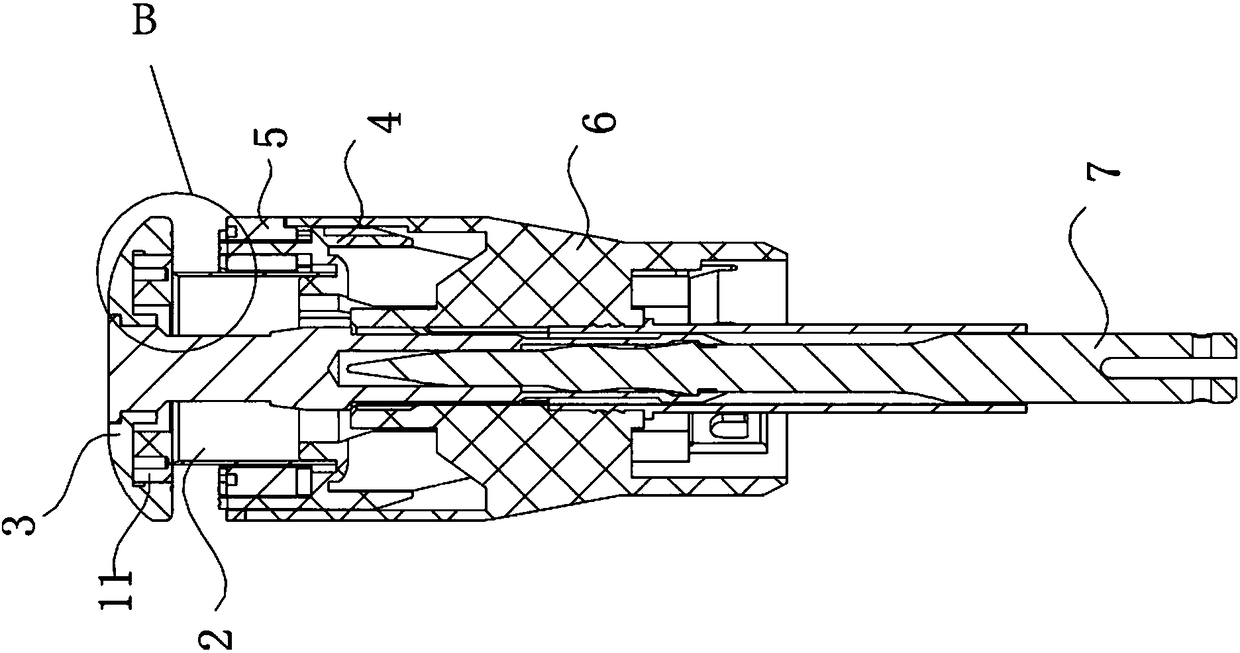

[0023] like figure 1 As shown, the embodiment of the present invention provides a stapler with a cutting mechanism A, the cutting mechanism A includes a combined anvil 1 with a hollow structure, such as figure 2 As shown, the combined anvil 1 includes a first layer of anvil 11 , a hollow layer 12 and a secondary support 13 . Optionally, the above-mentioned first-layer anvil 11 is a thermosetting polymer material, and / or the above-mentioned secondary support 13 is a stainless steel metal piece. The above-mentioned hollow layer 12 can make the cutting knife suddenly lose its support after breaking through the first layer of thermosetting polymer material support, so as to obtain an acceleration and rush to the second layer of stainless steel support.

[0024] like image 3 and Figure 4 As shown, the above-mentioned cutting mechanism also includes a cutting knife 2 , a nail abutment component 3 , a nail pusher 4 , a nail cartridge 5 , a head shell 6 and a firing rod 7 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com