Cucumber automatic cultivation system

A cucumber, automatic technology, applied in the field of cultivation system, can solve the problems of high work intensity, high labor cost, poor planting quality, etc., achieve the effect of improving growth stability, convenient pruning work, and improving growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

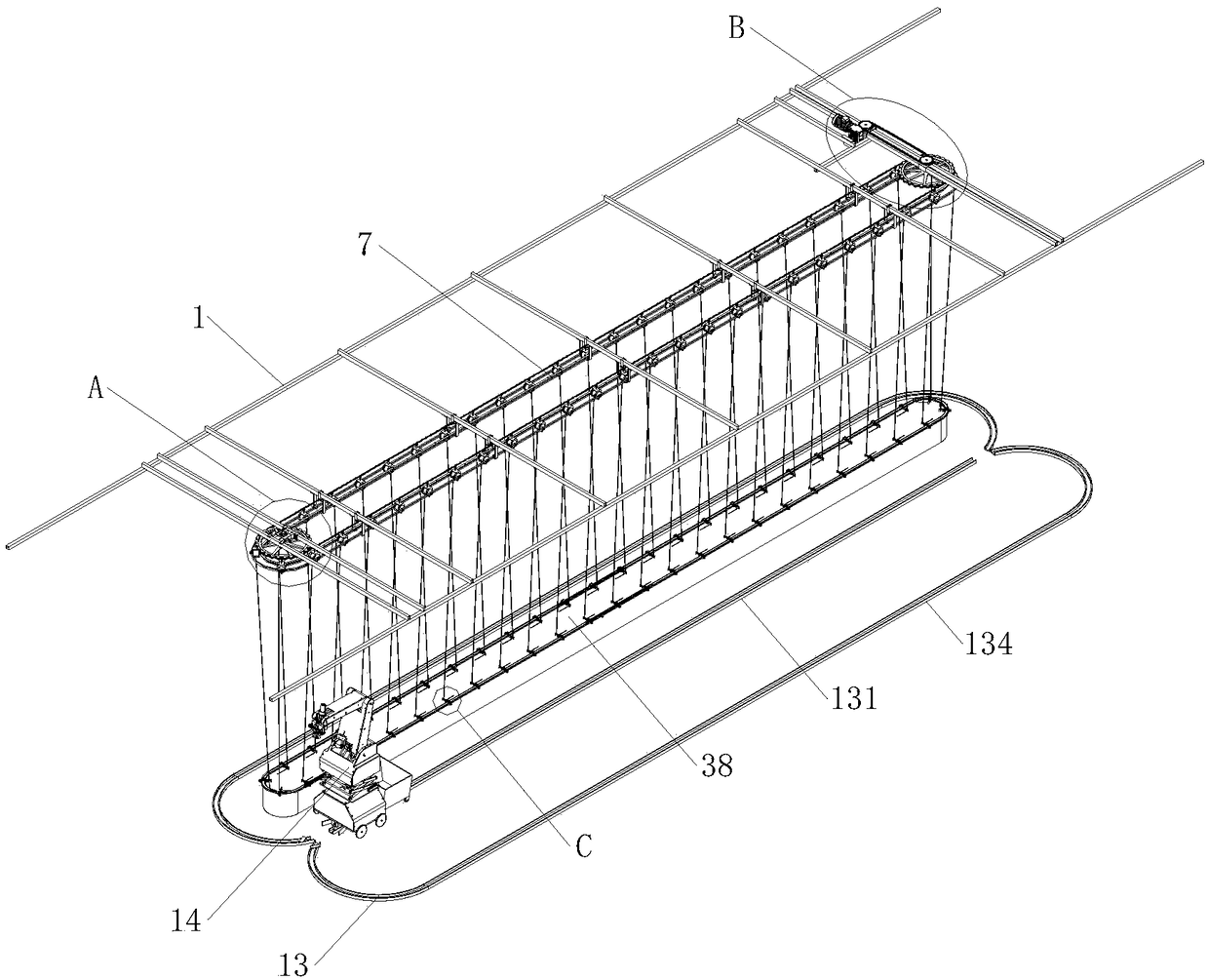

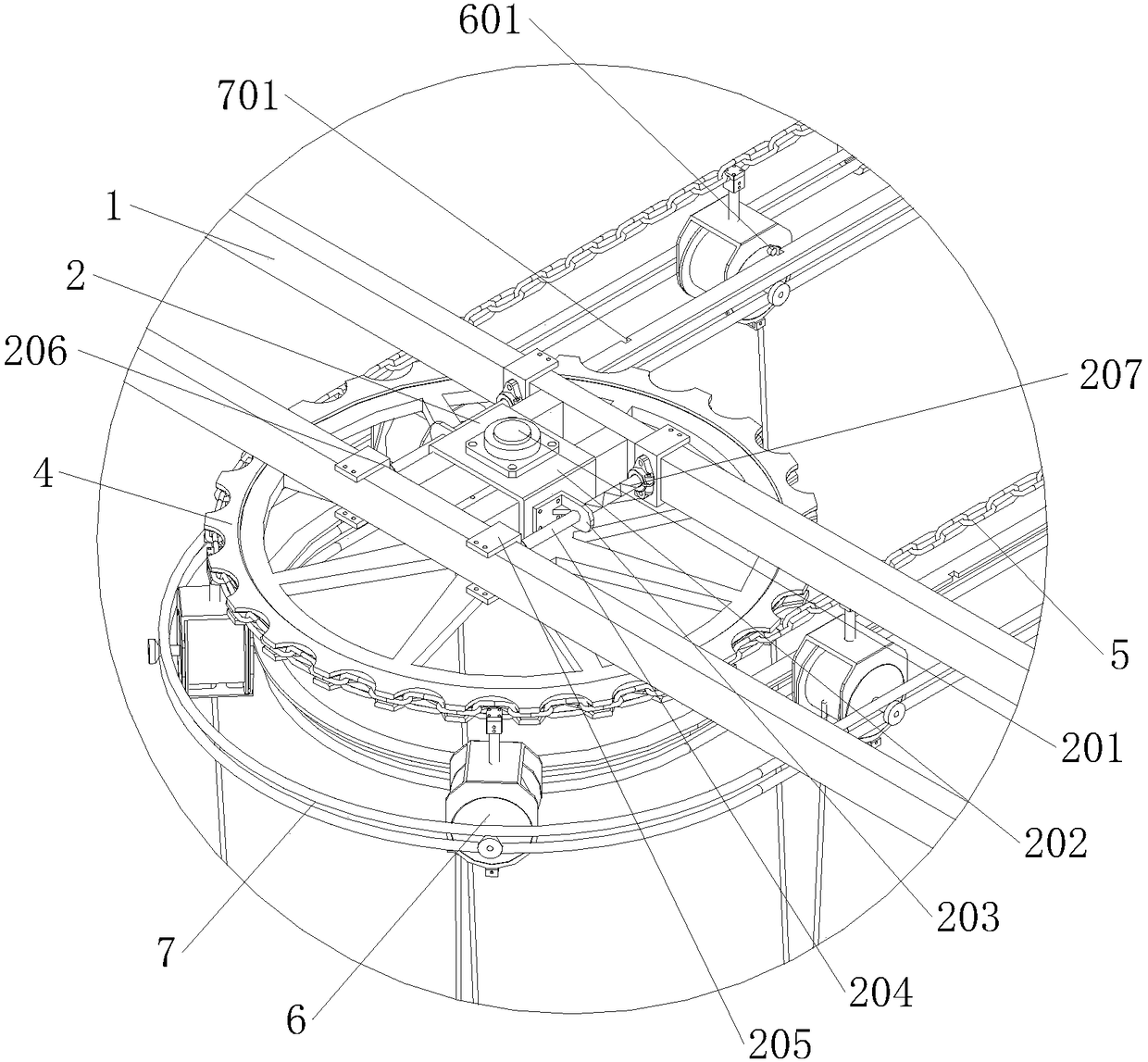

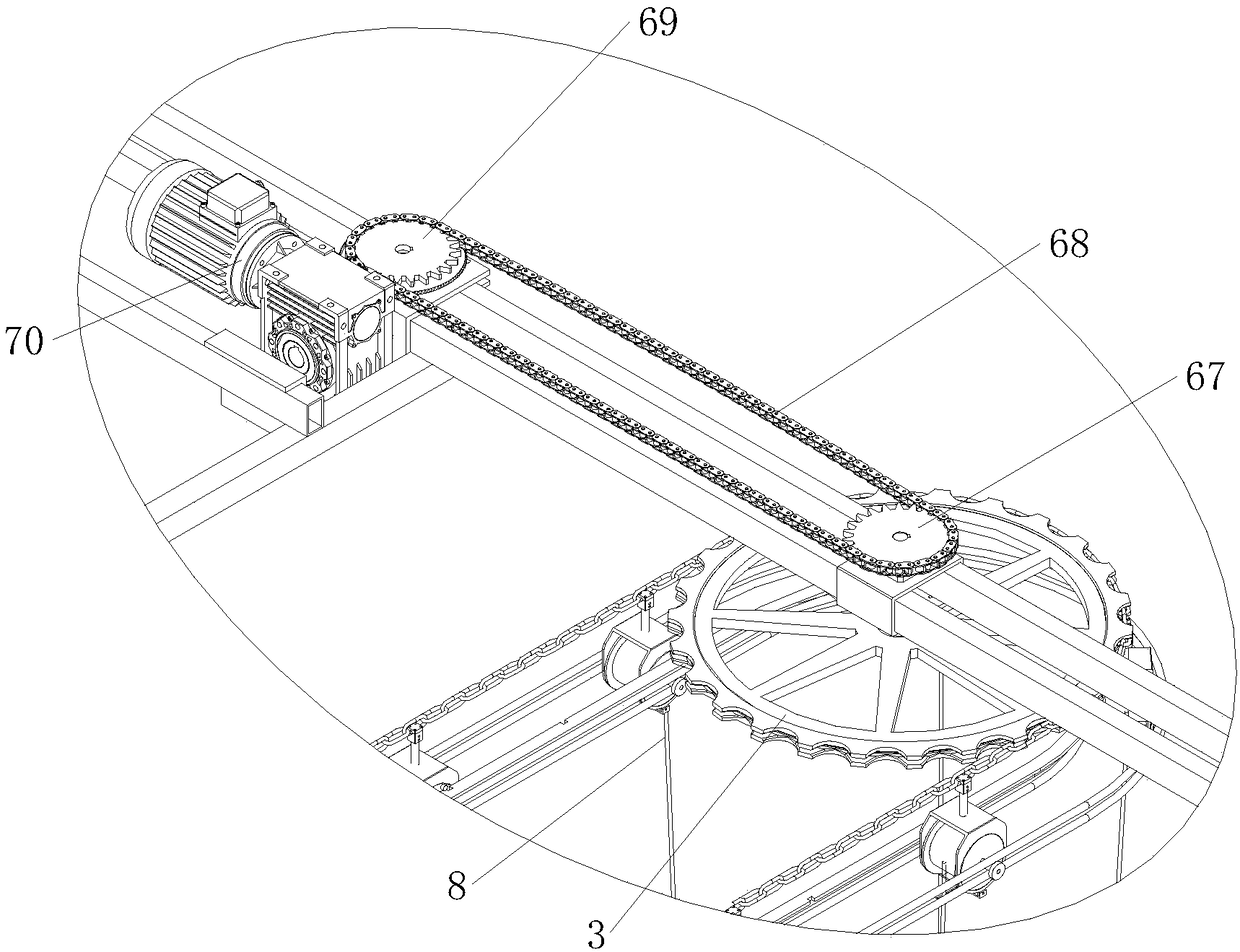

[0033] Example. Cucumber automatic cultivation system consists of figure 1 As shown, the beam bracket 1 is included, the two sides of the beam bracket 1 are respectively connected with the driving ring sprocket 3 and the driven ring sprocket 4 through the sprocket fixing device 2, and the outside of the driving ring sprocket 3 and the driven ring sprocket 4 are connected through the ring The chains 5 are connected to each other, and a plurality of winders 6 are arranged at the same interval on the endless chain 5. The center of both sides of the winders 6 is provided with an annular double-layer track 7 fixed on the lower end of the crossbeam bracket 1, and one side of the winders 6 is provided with There is an eccentrically arranged rotating pin 601, and a rectangular groove 701 cooperating with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com