A Method for Accurately Measuring the Lateral Resolution of a Focused Ultrasound Transducer

A technology of lateral resolution and focused ultrasound, applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as the impact of imaging clarity and the complexity of the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The invention provides a method for accurately measuring the lateral resolution of a focused ultrasonic transducer.

[0027] The method steps are as follows:

[0028] (1) Processing the stainless steel material into a cube test block;

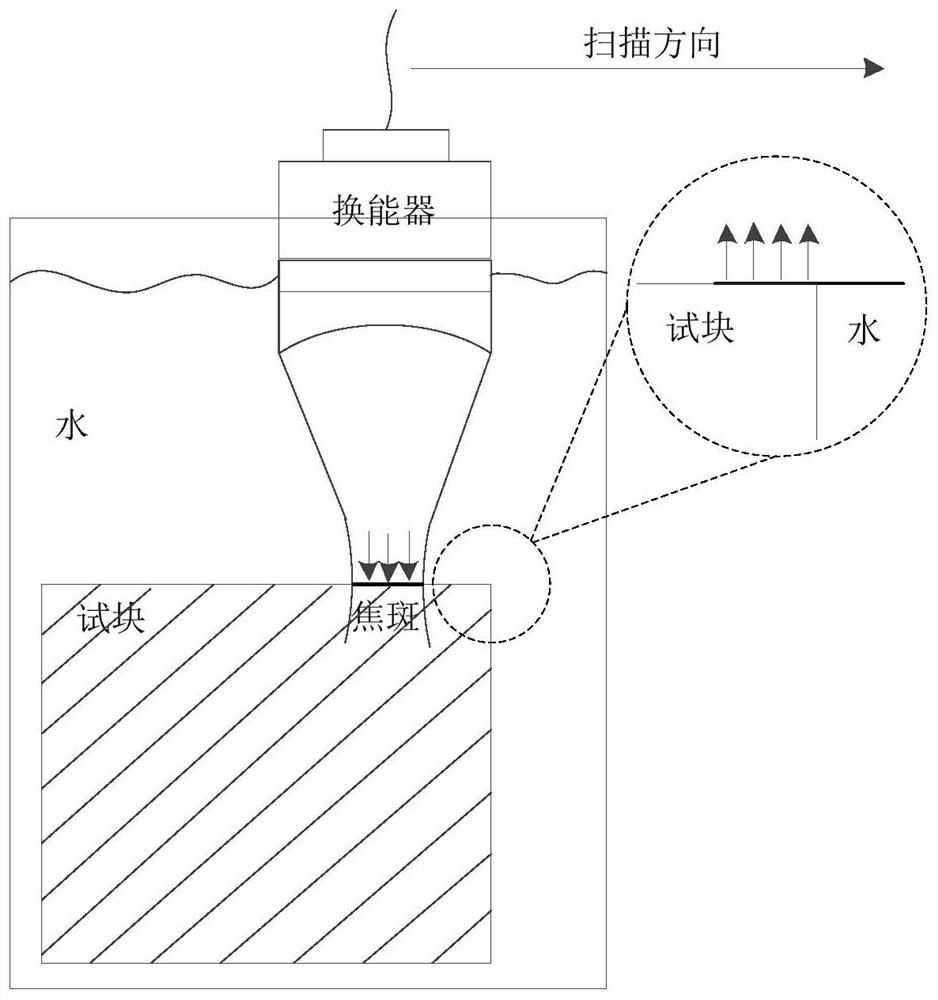

[0029] (2) Carry out high-precision C-scan imaging to the edge of the cube test block prepared in step (1) with the focused ultrasonic transducer to be tested;

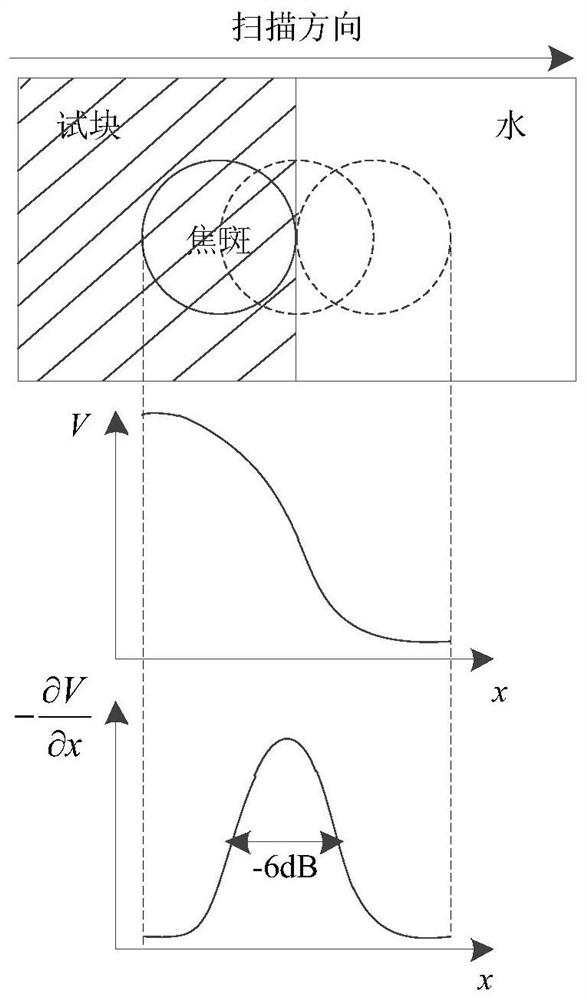

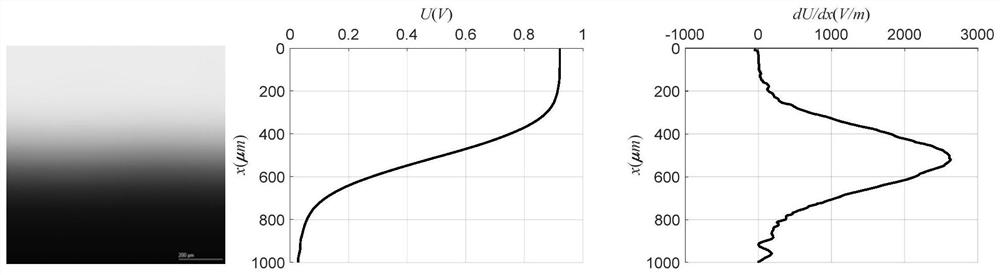

[0030] (3) Randomly select 10 gray value curves V(x) perpendicular to the edge of the test block in the C-scan image in step (2), average them and then use the mean value filter method to smooth the gray value curves;

[0031] (4) Derivation operation is performed on the smoothed gray value curve in step (3) to obtain the gray value change rate curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com