Gas stove valve anti-leakage anti-explosion combined system

A combined system and gas furnace technology, applied in heating fuel, household stove/stove, gaseous heating fuel, etc., can solve problems such as indoor pipeline explosion, and achieve the effect of preventing pipeline explosion, system safety and reliability, and preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

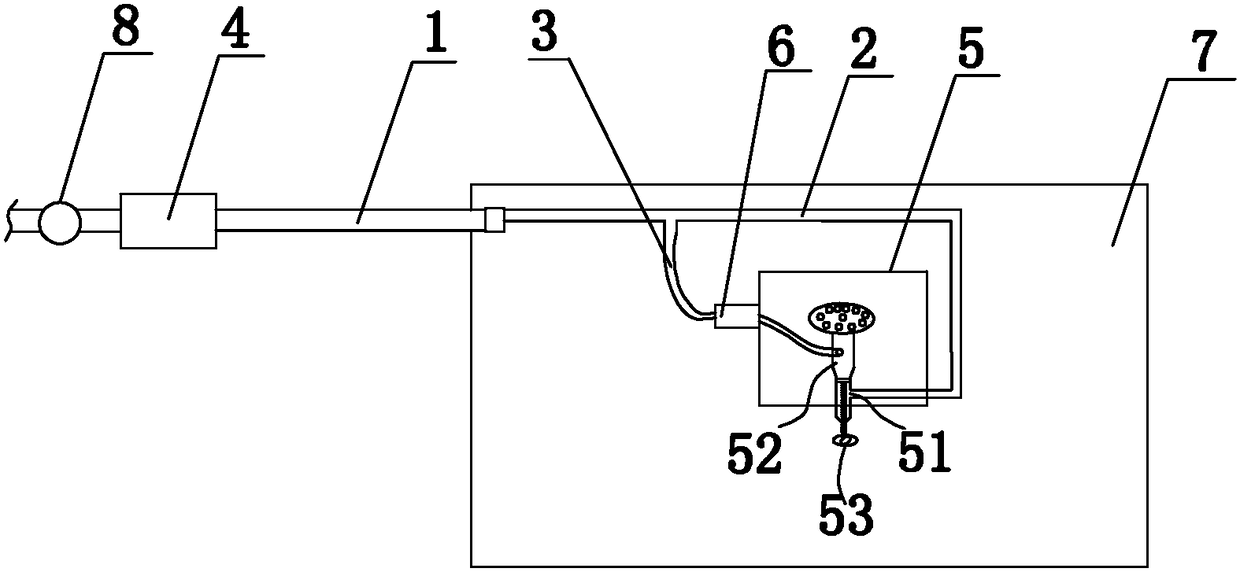

[0031] figure 1 It is a structural schematic diagram of a gas furnace valve leak-proof and explosion-proof combination system of the present invention, including a main pipe 1, a gas furnace main pipe 2, an anti-leakage valve 4, a gas furnace 5 and an explosion-proof valve 6, and the anti-leakage valve 4 and meter 8 are designed On the main pipeline and both are located outside the kitchen 7, one end of the main pipeline communicates with one end of the main pipeline of the gas furnace, and the other end of the main pipeline of the gas furnace communicates with the air inlet 51 of the gas furnace. The opening and closing of the air inlet is controlled by the ignition switch 53 of the gas stove. The main pipe of the gas stove is provided with a branch pipe 3, and the free end of the branch pipe is connected with the stove 52 of the gas stove. The explosion-proof valve is located at the branch. Pipelines, gas stoves and explosion-proof valves are located inside the kitchen.

[...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that two branch pipes are arranged on the main pipe, the free ends of the branch pipes communicate with the gas stove head, and each branch pipe is provided with an explosion-proof valve.

[0038] When the kitchen area is too large, multiple explosion-proof valves can be set inside the kitchen, and the explosion-proof valves can be opened in time when the kitchen encounters a fire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com