Lubricating device for maintaining equipment

A technology for lubricating equipment and maintenance equipment, applied in mechanical equipment, transmission parts, gear lubrication/cooling, etc., can solve problems such as operator personal injury, waste, safety hazards, etc., to avoid personal injury, avoid excessive or excessive Less, avoid the effect of position offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] as attached figure 1 As shown, a lubricating device for maintaining equipment includes a box body 1, and two clamping blocks 6 are slidably connected to the right side of the box body 1, and the two clamping blocks 6 are respectively located at the upper and lower parts of the box body 1 and are both Can slide along the vertical direction of the box body 1. A sliding shaft 5 is fixed on the box body 1 , and several limiting holes and pins 17 are provided on the sliding shaft 5 . When the clamping block 6 slides onto the sliding shaft 5 that can extend the sliding distance of the clamping block 6 , the pin 17 can be inserted into the limiting hole to limit the clamping block 6 .

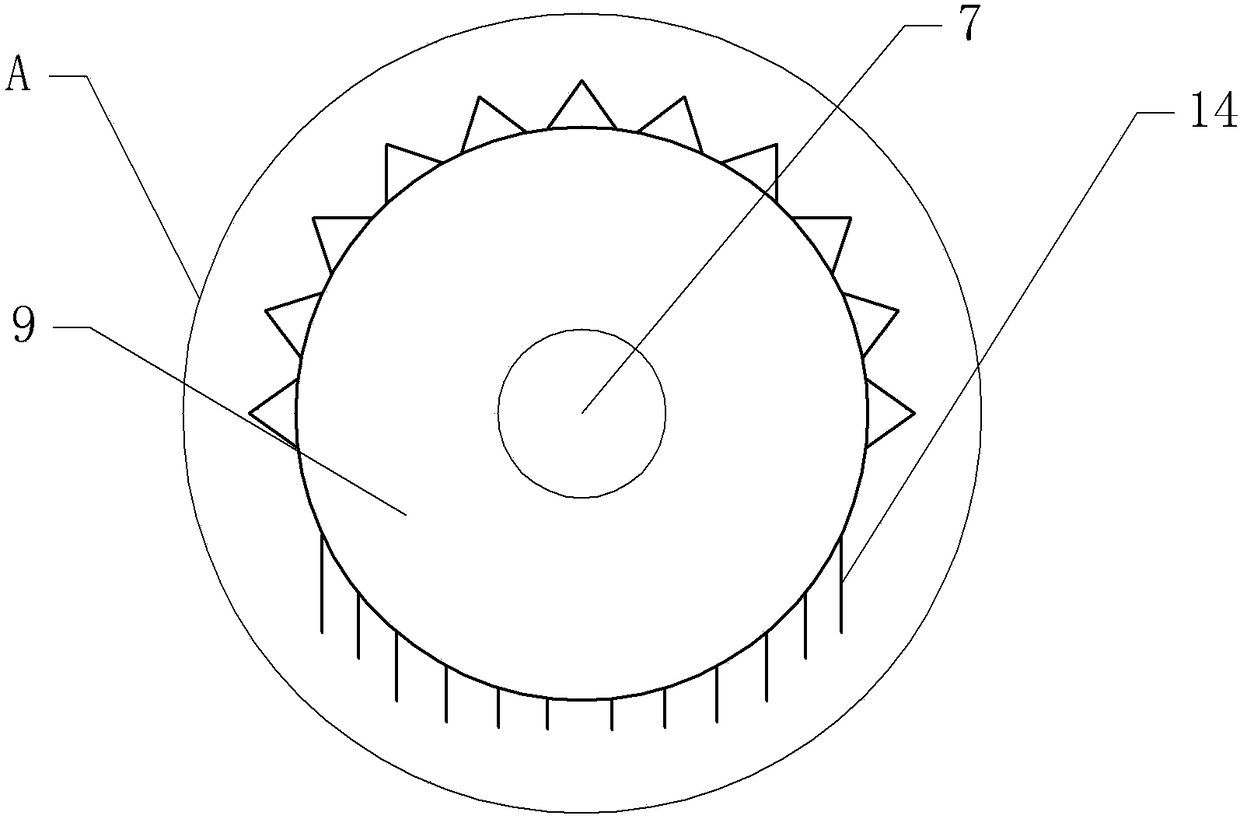

[0023] The clamping block 6 is provided with an oil chamber 13 , a servo motor 7 , an incomplete gear 9 and a button switch 8 . The servo motor 7 is fixed on the right side of the clamping block 6 by fastening bolts, and the servo motor 7 is electrically connected with a button switch 8 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com