Lifting frame for detection jig

A technology for testing jigs and lifting frames, which is applied in lifting frames, lifting devices, etc., can solve the problems of increasing manual labor, people are prone to fatigue, etc., and achieve the effect of improving testing comfort and reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

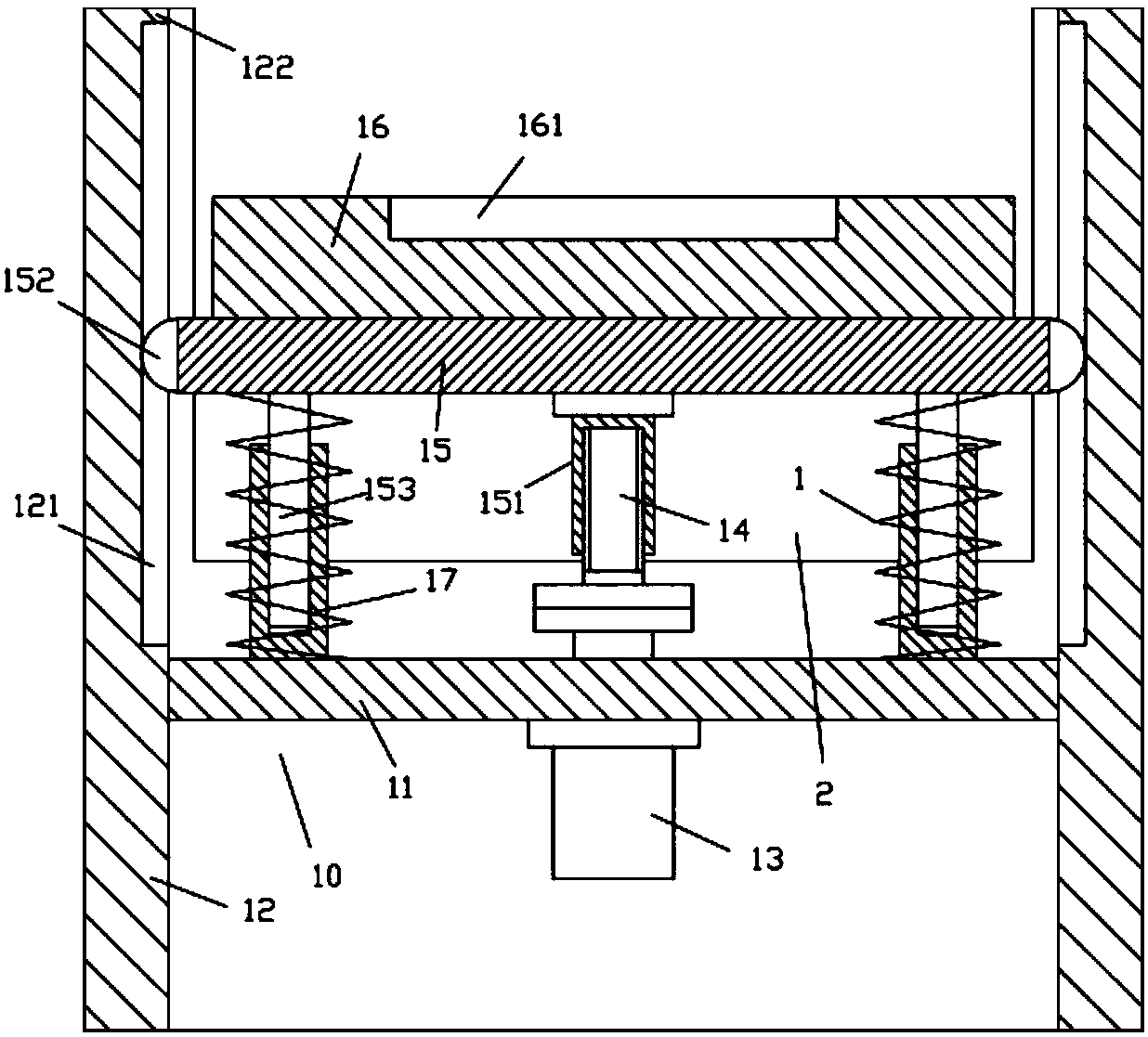

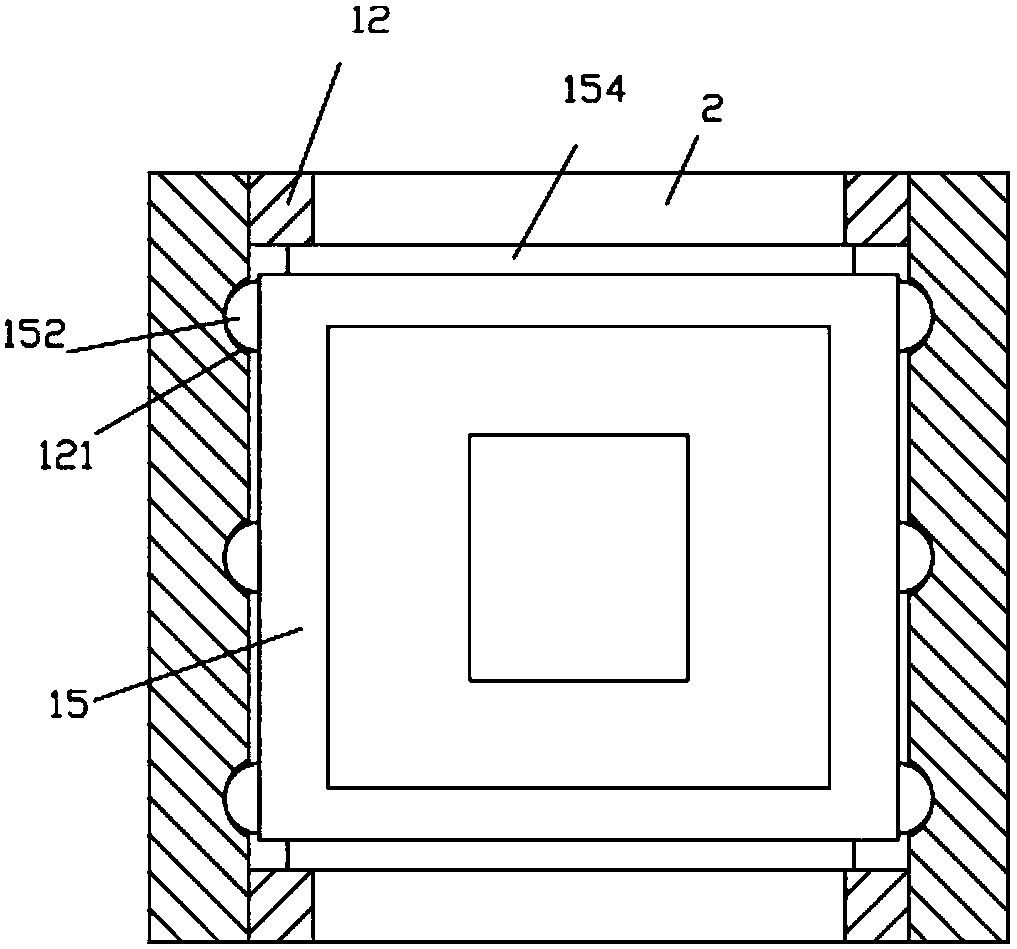

[0015] Examples, see e.g. Figures 1 to 2 As shown, a lifting frame for a detection fixture includes a frame 10, and the frame 10 includes a main base plate 11, the four side walls of the main base plate 11 are fixed with vertical support plates 12, and the side walls of the main base plate 11 Fixed on the inner side wall of the middle part of the vertical support plate 12, the bottom surface of the middle part of the main base plate 11 is fixed with a lifting motor 13, the output shaft of the lifting motor 13 passes through the main base plate 11 and is connected with a vertical screw rod 14 through a coupling, and the lifting plate 15 is located above the main bottom plate 11, the bottom surface of the middle part of the lifting plate 15 is fixed with a vertical screw sleeve 151, and the vertical screw rod 14 is screwed in the vertical screw sleeve 151;

[0016] A plurality of hemispherical self-lubricating blocks 152 are fixed on the left and right side walls of the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com