A shift control system and method for a hybrid electric vehicle

A hybrid electric vehicle and control system technology, which is applied in the field of hybrid electric vehicles and the shift control system of hybrid electric vehicles, can solve problems such as poor synchronization, reduced transmission accuracy, and impact on driving experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

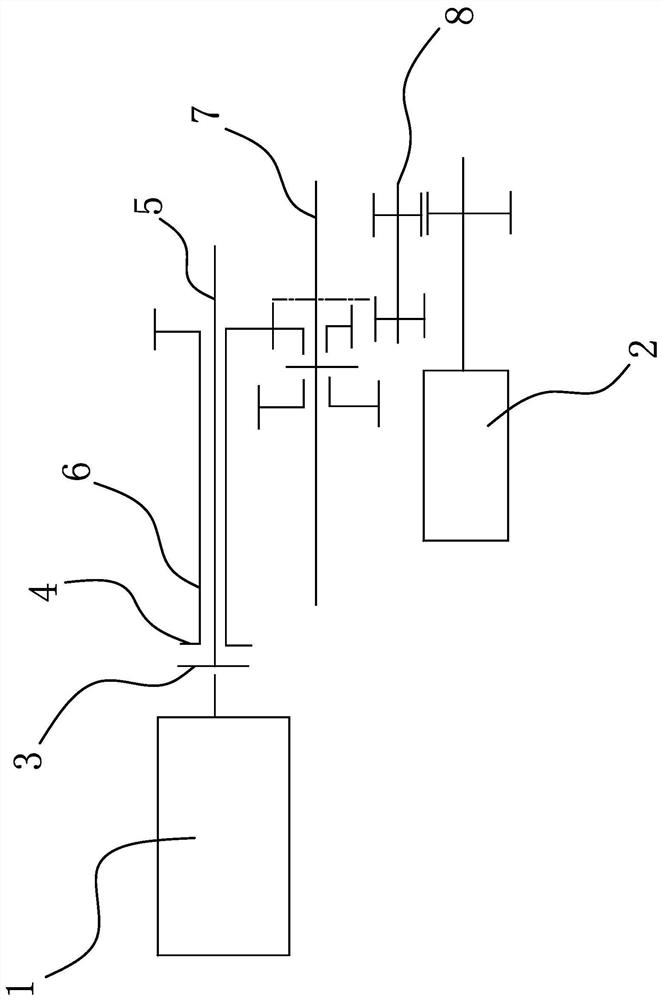

[0037] Such as figure 1 As shown, the automobile of this embodiment is a gasoline-electric hybrid automobile, which adopts a wet dual-clutch transmission for power transmission. The dual-clutch transmission includes an inner clutch 3, an outer clutch 4, an input shaft, an output shaft 7 and a gear shaft 8, wherein the input The shaft includes odd-numbered gear input shaft 5 and even-numbered gear input shaft 6, the even-numbered gear input shaft 6 is a hollow shaft, the even-numbered gear input shaft 6 is sleeved on the odd-numbered input shaft, and the odd-numbered gear input shaft 5 and the even-numbered gear input shaft 6 pass The inner clutch 3 and the outer clutch 4 are connected with the engine 1, the odd-numbered ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com